A lawn mowing robot company valued at over 100 million yuan is facing difficulties in fulfilling its crowdfunding deliveries, and the upheaval among small and medium-sized players is just beginning.

Author | Huang Nan

Editor | Peng Xiaoqiu

In the past few years, it has been quite common to see cases where hardware startups failed due to mass - production issues. Now, this industry dilemma is playing out again in the lawn mowing robot market.

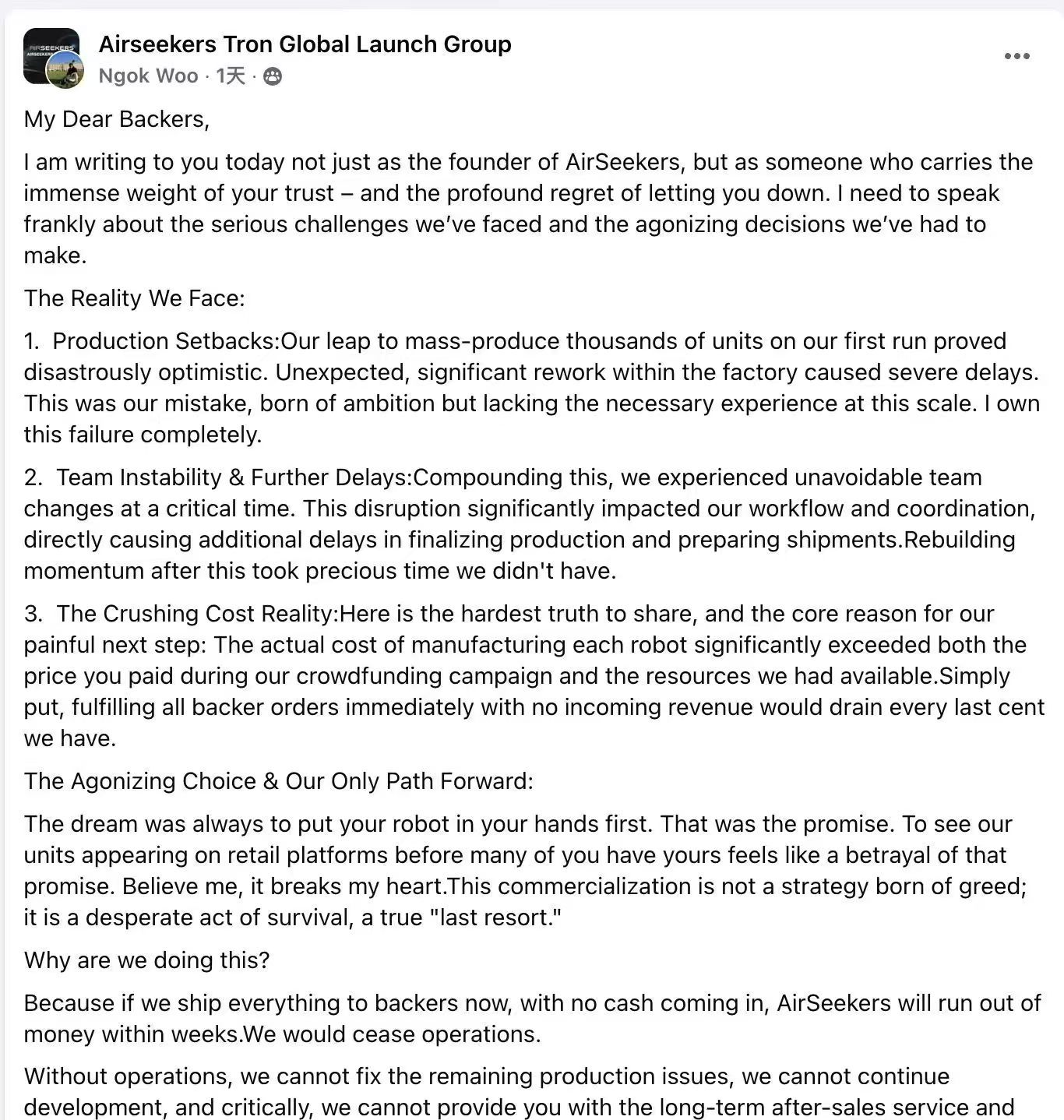

Recently, Changyao Innovation, a smart lawn mowing robot manufacturer, issued an announcement stating that the company is deeply troubled by three difficult problems and is facing a development predicament. Firstly, on the product production and delivery end, due to an underestimation of its own capabilities and the difficulty of mass production, the company overly optimistically planned the quantity for the first large - scale production (thousands of devices). As a result, rework occurred in the factory, and production was severely delayed.

Secondly, during the same period, personnel changes intensified the crisis. Personnel flow in the enterprise can cause obstacles to work synergy, lengthen the product R & D cycle, and further lead to additional delays in the final production and preparation for shipment.

Finally, Changyao Innovation is also in a severe cost dilemma. After internal accounting, the actual manufacturing cost of each lawn mower far exceeds the price promised to users during the crowdfunding and the company's existing capital reserve. Without new capital injection, if the company tries to fulfill all crowdfunding orders forcefully without corresponding revenue, it will quickly exhaust all of the company's funds.

Original text of Changyao Innovation's announcement (Source: Kickstarter)

This startup, which raised over $2.2 million in crowdfunding within a month, is finally stuck at the door of product delivery. Only nearly a hundred units of the first - batch orders have been delivered, and the enterprise has not yet given a clear answer on the delivery time for the remaining user orders.

In recent years, Changyao Innovation has completed two rounds of financing, with a cumulative amount of tens of millions of yuan. The investors include well - known institutions such as Gree Group, Tongchuang Weiye, Orient Fortune Sea, Blue Ocean Capital, Shuimu Wutong Capital, and Brizan Ventures. According to Hard Krypton, its latest valuation has exceeded 100 million yuan.

However, the lawn mowing robot market is never just a simple product competition. It is an all - around competition covering R & D, supply chain, cost control, and marketing. Any shortcoming in one link may trigger a chain collapse of the entire system.

The industry reshuffle is accelerating.

As the market heat continues to rise, the industry has entered a stage of in - depth integration. The cruelty of this elimination competition far exceeds expectations. Enterprises without systematic product strength will eventually be eliminated. It is foreseeable that, not limited to Changyao Innovation, the list of struggling players may continue to grow.

Fatal mistakes in the production process

In the hardware field, there is an insurmountable gap between beautiful Demo data and real - world mass production.

Specifically in the production process, it can be divided into two different stages: small - batch trial production and mass production. Among them, small - batch trial production includes the DVT (Design Verification Test), EVT (Engineering Verification Test), and PVT (Production Verification Test) stages.

Trial production mainly focuses on problem troubleshooting and optimization. For example, in the EVT stage, basic design defects are solved; in the DVT stage, processes and designs are optimized to improve reliability; in the PVT stage, the production process and supply chain synergy are improved. Then, when entering the mass - production stage, by strictly following the standardized process, the consistency of product quality can be guaranteed, costs can be controlled, production capacity can be increased, and the stability and efficiency of production can be maintained.

Changyao Innovation adopted a relatively aggressive production capacity planning strategy in the production management process. An industry insider close to Changyao Innovation told Hard Krypton that it completed the testing of nearly 500 prototype units in less than three weeks during the DVT stage. In contrast, the industry average duration is 4 - 6 weeks. Then, in the PVT stage, it quickly increased the production capacity to 2500 units, an increase of up to 500%, far exceeding the industry's safety threshold of 200% - 300%.

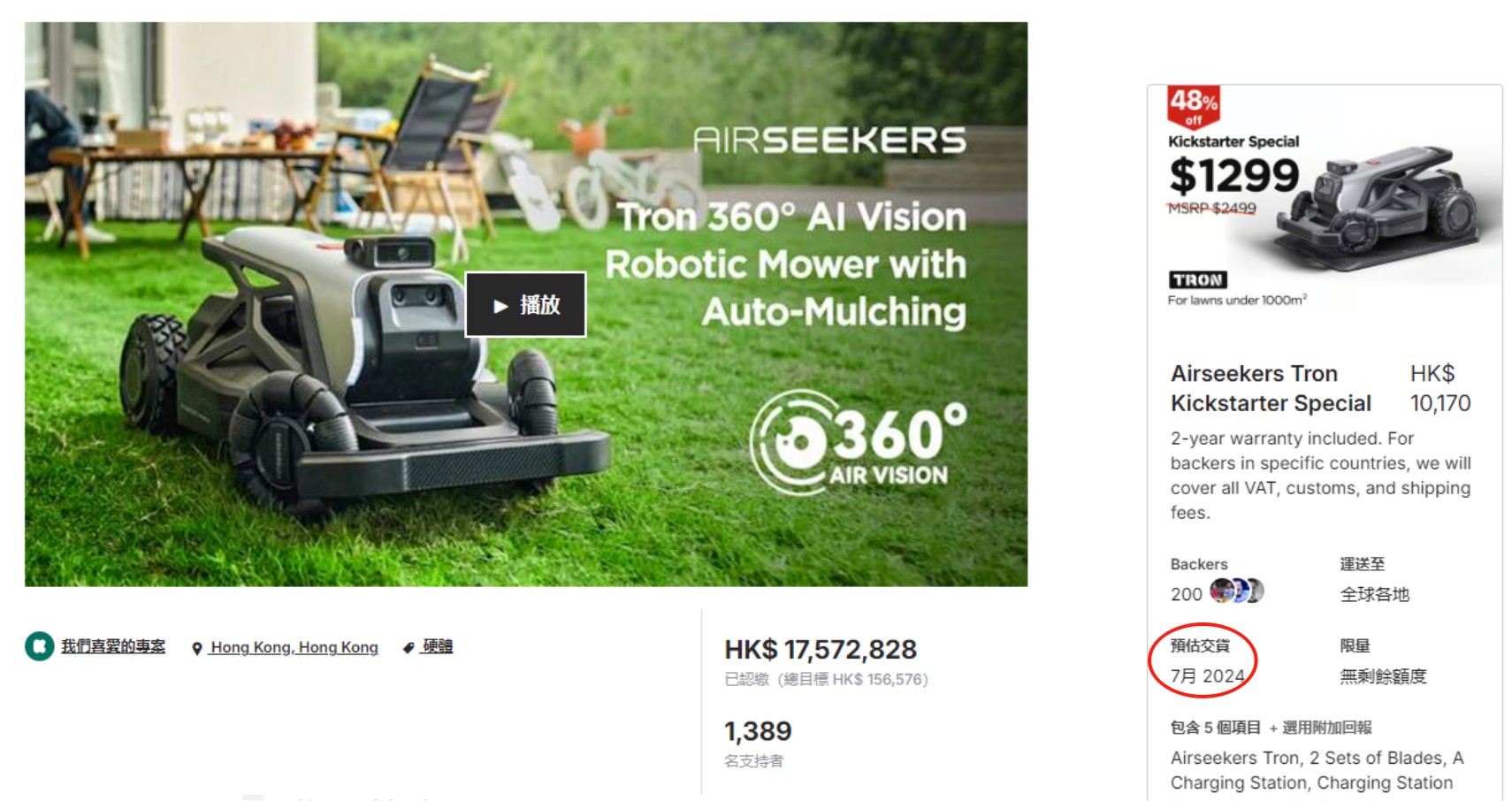

The Kickstarter page shows that the estimated delivery time of the product is July 2024 (Source: Kickstarter)

Migrating the idea of rapid development and iteration of Internet products to the hardware manufacturing field, to some extent, ignores the foundation of structural quality. The seemingly efficient early results also cover up the complexity of large - scale production. "It's like driving a racing car right after getting a driver's license. The speed goes up, but quality control, supply chain management, and production scheduling are likely to get out of control. Once the quantity reaches thousands or even tens of thousands of units, large - scale rework is inevitable," the above - mentioned insider said.

On the other hand, as the lifeline of hardware companies, BOM cost (Bill of Materials cost), it can be seen that Changyao Innovation also has certain systematic mistakes in its cost control and pricing strategy.

According to the healthy industry standards, the financial reports of leading enterprises such as iRobot and Ecovacs show that the BOM ratio of mature products is mostly stable in the range of 18% - 22%. Xu Bin, an investor who has long been concerned about the hardware market, told Hard Krypton that some due - diligence standards clearly require that the BOM ratio of Pre - A round projects should be controlled within 25% and compressed to below 20% in the mature stage.

The production workshop of Changyao Innovation (Source: the enterprise)

Based on the pricing of Changyao Innovation's Airseekers Tron product, its price on Kickstarter starts at $1299. Therefore, the optimal BOM cost should be controlled below $325.

According to insiders, the BOM cost of Changyao Innovation may account for more than 30% of the selling price, which is higher than industry standards and investment requirements. This will not only squeeze the company's profit margin but also make it prone to losses when facing price increases of materials such as chips and motors. It may also fail to meet the due - diligence standards of the capital market due to high costs, affecting the financing process and exacerbating the already tight capital - chain pressure.

During this period, Changyao Innovation also tried to improve cash flow by reducing costs, including reducing material costs and manufacturing expenses. However, these partial optimizations have never fundamentally solved the structural cost problem.

More importantly, Changyao Innovation launched its crowdfunding in April 2024 and officially announced the completion of the Pre - A round of financing in November of the same year. The financing was seven months behind the completion of the crowdfunding, resulting in a capital vacuum during the critical production material preparation period. There is a timing mismatch in capital planning.

This operation model, which uses more than $2.2 million in crowdfunding funds to cover 1389 orders but is actually only enough to cover the production cost of hundreds of products and relies on subsequent financing to make up for the capital gap, undoubtedly has extremely high sustainability risks.

The production workshop of Changyao Innovation (Source: the enterprise)

Hu Yue, the founder of Changyao Innovation, pointed out in an exclusive interview with Hard Krypton that for a startup with a scale of 60 to 70 people, from the early stage to the production of EVT equipment, the cost is about 30 - 40 million yuan, personnel expenses are about 30 million yuan, and mold - opening costs are 5 - 6 million yuan. Excluding inventory, about 60 million yuan is needed for mass production. With working capital, at least 100 million yuan is required to achieve complete shipment and form a scale.

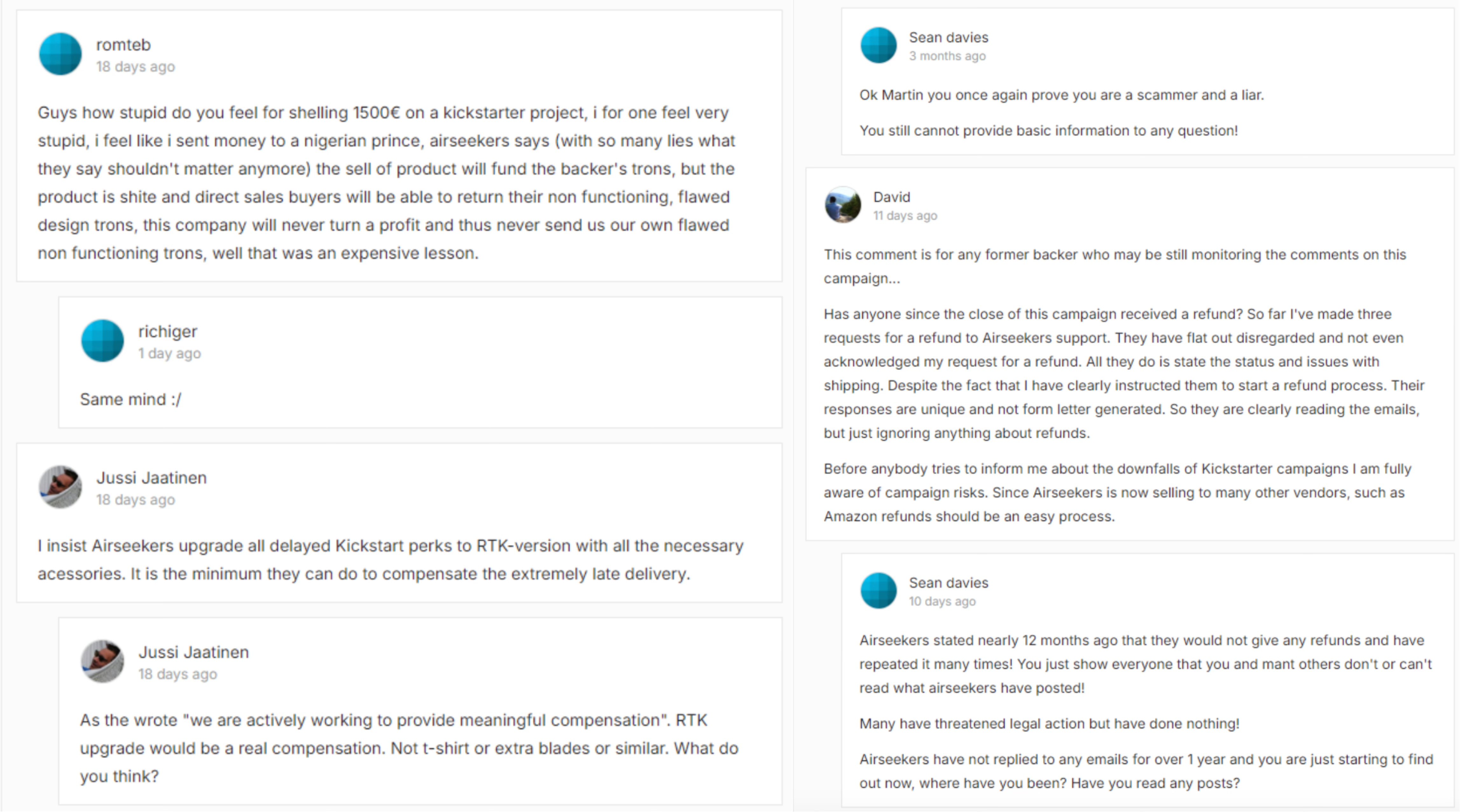

Aggressive production capacity planning, underestimated manufacturing costs, and mismatched financing rhythms have put Changyao Innovation in a dilemma during the critical delivery period: if it prioritizes the delivery of crowdfunding orders, it will exhaust all operating funds; if it focuses on commercial sales to maintain cash flow, it will inevitably delay the orders of supporters.

This dilemma has finally evolved into the current real - world crisis, which not only causes large - scale order delays but also further leads to the collapse of the enterprise's, the market's, and even users' confidence.

Messages from users on Kickstarter urging delivery (Source: Kickstarter)

The industry's window period is closing

Nowadays, the global lawn mowing robot market competition pattern shows obvious regional differentiation. Among them, the competition in the European lawn market is more intense than that in North America. The main reason is that the European market is more mature and the entry threshold is relatively fixed, and the competition pattern is becoming more stable.

According to the "Combustion Ban" policy passed by the EU in 2022, it is clearly stipulated that since 2024, the sale of small garden machinery such as fuel - powered lawn mowers has been prohibited within the EU. This policy has forced the elimination of fuel - powered lawn mowers and directly promoted the rapid popularization of electric products.

Against this background, Chinese smart lawn mower brands are also accelerating to seize the market share released by the policy dividend through the intelligent replacement of traditional garden tools.

It can be clearly seen that since last year, lawn mowing robot manufacturers have all been in a stage of collective volume growth. The shipment volume of Ninebot in 2024 exceeded 140,000 units; the brand sales volume of Kuma Technology in Europe and America reached 80,000 units in 2024; the sales volume of Ecovacs' GOAT series exceeded 80,000 units in 2024; Dreame announced in February this year that its shipment volume exceeded 100,000 units; MOVA announced in June that the shipment volume of its lawn mowing robot exceeded 100,000 units.

The first product of Changyao Innovation, Airseekers Tron (Source: the enterprise)

In terms of market positioning, Changyao Innovation's choice to focus on the small lawn market of less than 1000 square meters faces multiple disadvantages.

Firstly, in terms of product strength, its first product, Airseekers Tron, proposes a pure vision solution based on a dense map. Although it has certain characteristics, its advantage lies in relatively low cost. It can obtain rich environmental information through a multi - camera vision system and, combined with "lawn crawling pattern technology" and "rotation - unbiased algorithm" and other innovations, can identify common obstacles and achieve "autonomous driving" on the lawn. At the same time, the construction of a dense map helps to improve the accuracy of path planning and enhance operation efficiency.

However, affected by the characteristics of the vision solution, lawn mowing robots are also easily interfered with by changes in light. Under complex light conditions such as strong light, backlight, or rainy days, the recognition accuracy may decline, and it is difficult to recognize objects with inconspicuous features, such as low - lying small stones and withered grass, which will affect the obstacle - avoidance effect.

The Tron 360° AI vision lawn mowing robot with automatic crushing function (Source: the enterprise)

The person - in - charge of a lawn mowing robot manufacturer told Hard Krypton that the vision solution requires continuous feeding of massive data, which not only has high training costs but also has a longer cycle from data preparation to algorithm learning and optimization. According to the insider, Changyao Innovation also experienced significant delays in the product R & D rhythm due to this and later switched to an external algorithm solution.

In addition, the problems of slow data processing speed and poor real - time performance still exist. Although a dense map can improve the accuracy of path planning, it takes longer to build the map, increasing the user's initial usage cost. Coupled with the fact that the gap between its core technical indicators and the industry's open - source solutions is rapidly narrowing, it is difficult to gain an advantage over mainstream competitors such as Ninebot, Dreame, and Kuma, and thus lacks more attractive differentiated selling points.

In contrast, large manufacturers can rely on the advantages of large - scale production and supply chain to reduce costs. As a startup, Changyao Innovation has a limited production scale in the early stage, so it is at a disadvantage in price competition and cannot compete with established enterprises such as STIHL and Positec in terms of brand premium.

Its shortcoming in channel construction is even more obvious. Lawn mowers are durable goods with a high customer - unit price and a long service cycle. Therefore, users are often more cautious when purchasing and will fully refer to market reputation and user feedback. This also makes local agents more conservative when introducing products. They generally will not easily cooperate with startups that have no brand awareness or market influence in the local area.

In contrast, large manufacturers have accumulated high brand awareness through early - stage layout and have established stable cooperative relationships with mainstream local garden building material channels and home furnishing chain stores in Europe. Their brand reach and product distribution capabilities far exceed those of startups like Changyao Innovation, which will further squeeze its survival space in the small lawn market.