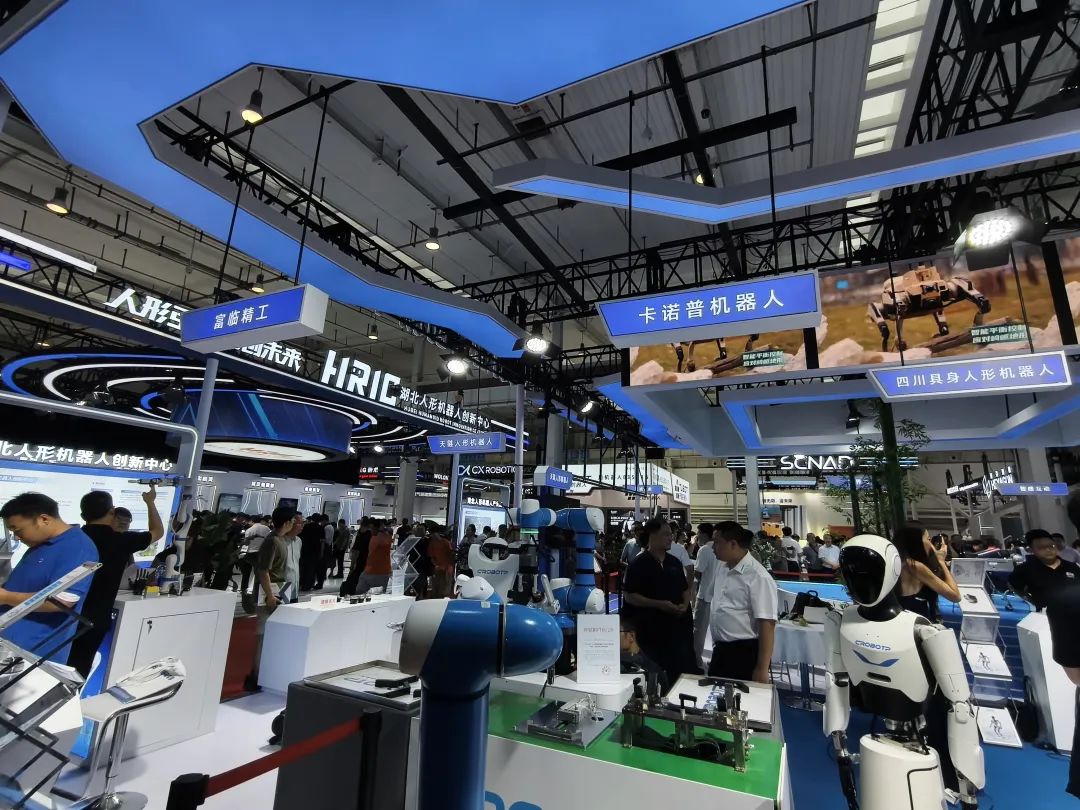

Oh no! I'm surrounded by robots in Beijing, so many that it seems like there are an endless stream of them!

Last month, the author of Negative Reviews visited the World Artificial Intelligence Conference.

At that time, the biggest feeling was: "Did I go to the wrong place?"

Wasn't it supposed to be an artificial intelligence conference? But everyone there seemed to be working on robots.

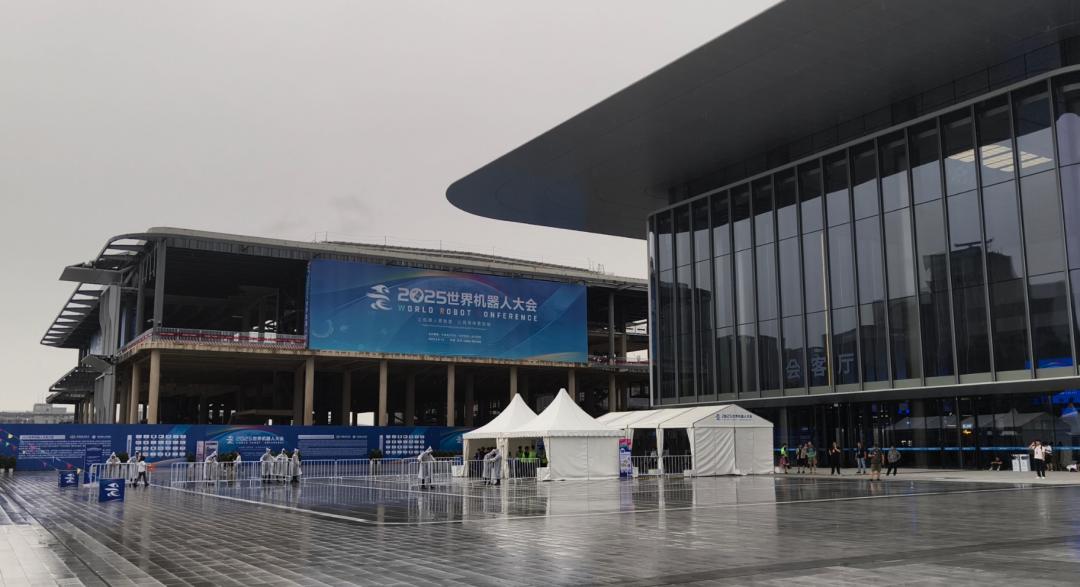

So this month, the author specifically went to the World Robot Conference in Beijing. To the author's surprise, the most prominent thing at this conference wasn't actually robots.

Instead, it was a sea of people who came from all over the country to see the robots...

Every booth was crowded. If the brand was well - known, the situation would be even more chaotic.

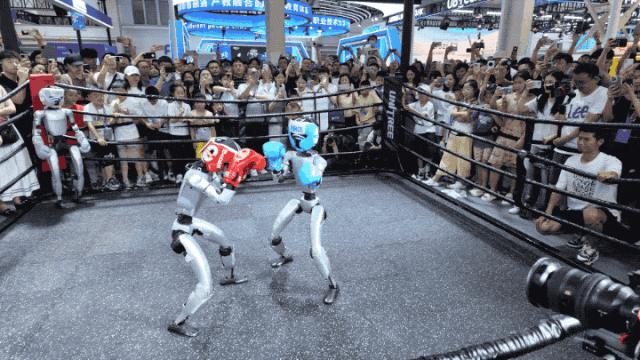

Take the Unitree booth, which was on the Spring Festival Gala this year, for example. People surrounded it three - deep to watch the robots fight each other and capture precious video footage of what it would be like for early humans to enslave robots. The author couldn't even squeeze in.

The robots from other industries were also quite diverse. After visiting the exhibition, the author had only one thought:

Everything can be a robot, and everyone is making robots.

Not only the robot manufacturers came, but also those who teach people how to make robots.

OK, without further ado, let's start with the robots at the exhibition, which are becoming more and more refined and practical:

There's no need to dwell on traditional humanoid robots. This year, these robots seem to walk much more steadily than before.

A swaggering gait

Moreover, people are paying more and more attention to the details of robots. Some manufacturers focus on making robot heads, while others specialize in researching robot hands. Even for the fingers, some manufacturers have started to develop sensors for in - depth study.

The author saw an extremely lifelike robot head at the exhibition. After inquiring, it was found that platinum silicone was used (yes, the same kind as some dolls). The degree of simulation was comparable to that of a wax figure, and the facial expressions were incredibly flexible.

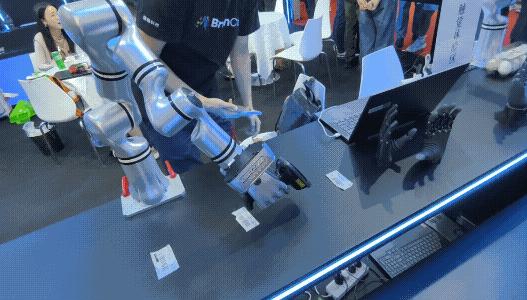

In addition, the manipulative skills of robots have improved this year. Besides simple tasks like holding two clips to fold clothes or sort goods as in the past...

They are now learning from humans, growing five fingers and even playing the piano like us.

There was also a robotic hand on display by a company that could remotely synchronize human movements. It could even pick up and knead a plastic ball.

There was also a force - feedback glove on display. Through this highly sci - fi glove, the force felt by the robotic hand could be remotely transmitted to the human hand through vibration.

In the future, when we remotely control robots, we can feel what the robot touches through the vibration of the glove. It's getting closer and closer to the scenarios in sci - fi movies.

Yes, it's the robotic hand in the bottom - right corner that looks like an exoskeleton

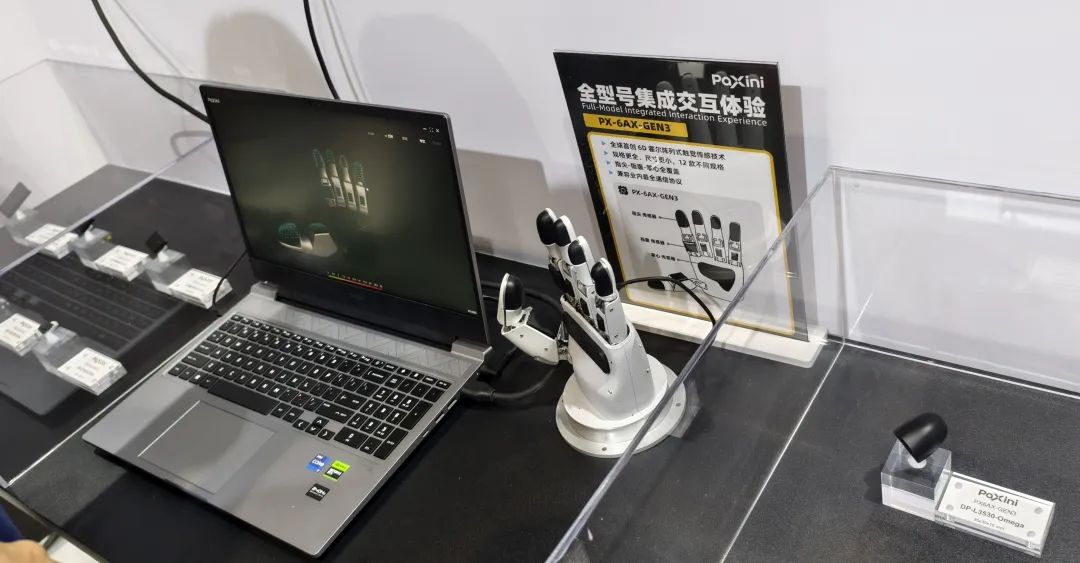

Making robot heads and hands isn't the limit of the "granularity" at this exhibition. The author also saw a company that specializes in making robot fingers.

With this small sensor, the robot can sense whether its finger touches something and the direction and intensity of the force when it does.

These two parameters seem simple but are extremely important for a robot to pick up objects.

Just like when we eat hot pot and use chopsticks to pick up tofu from the spicy soup, we must constantly control the force to pick up the crispy tofu.

The same goes for robots. Once they grasp an object, they must immediately adjust the force on their hands to handle different objects.

Therefore, fingertip sensors are essential for advanced dexterous hands. At the exhibition, we found that there were quite a few manufacturers specializing in such sensors, and their technical routes were diverse.

Some use resistivity calculations, some use capacitance, and more advanced ones use Hall elements. The staff of one company told us that currently, the more advanced dexterous hand manufacturers would buy their fingertip sensors.

By now, you may have noticed that at this exhibition, not only were there various robots on display, but also the supply - chain manufacturers closely related to the industry were present, which was unexpected.

Take the manufacturers of robot hands mentioned above. They come in all shapes and sizes. You might see hands from all directions in one place, and there are even some strange - looking ones twisted like a twist, and some with only three fingers.

I'm wondering if a three - fingered thing is just a clip. Why is it called a hand?

Moreover, more importantly, the prices have come down, and the degree of localization is quite high.

An exhibitor told us that in the past, they had to buy important motors and other components from Germany for their prototype machines. But this year, with the emergence of domestic motors, their new models not only have a more streamlined and beautiful appearance but also have their prices reduced from tens of thousands or even more than a hundred thousand yuan to just twenty thousand yuan.

Moreover, these twenty - thousand - yuan dexterous hands are made with delicate metal shells and even come with fingertip force sensors that can pick up an egg.

At other booths, you can see various hands from other manufacturers, also priced at around twenty thousand yuan, but with different craftsmanship. Some that focus on portability use plastic parts, while those that emphasize load - bearing capacity use steel structures, and some even use cable drives.

Wang Xingxing from Unitree Technology said at the conference that in the first half of this year, the robot industry was booming. Both complete - machine manufacturers and component manufacturers achieved an average growth of 50% to 100%, which is quite rare for the entire industry. The demand side has driven the development of the whole industry.

On the one hand, the domestic robot industry has a demand for these components. In addition to the domestic motors and sensors mentioned earlier, exhibitors of transmission mechanisms, batteries, etc. were also present. Almost the entire domestic robot industry chain was on display here, giving the author the feeling that one could assemble a robot just with the things in this exhibition hall.

If Iron Man had this setup in the cave where he was trapped, he might have achieved mechanical ascension on the spot.

On the other hand, in addition to research and development and manufacturing, the demand for robot - related scenarios also plays a significant role in promoting the industry's development.

This time, even the robot distribution industry made an appearance. The first booth we saw when entering the exhibition hall was a robot - version 4S store and a robot - version 1688.

According to them, some robot factories focus on R & D and mainly deal with universities and research institutes. It's indeed difficult for them to provide services and after - sales support for general users. So they help users connect with manufacturers, customize products, and provide after - sales services.

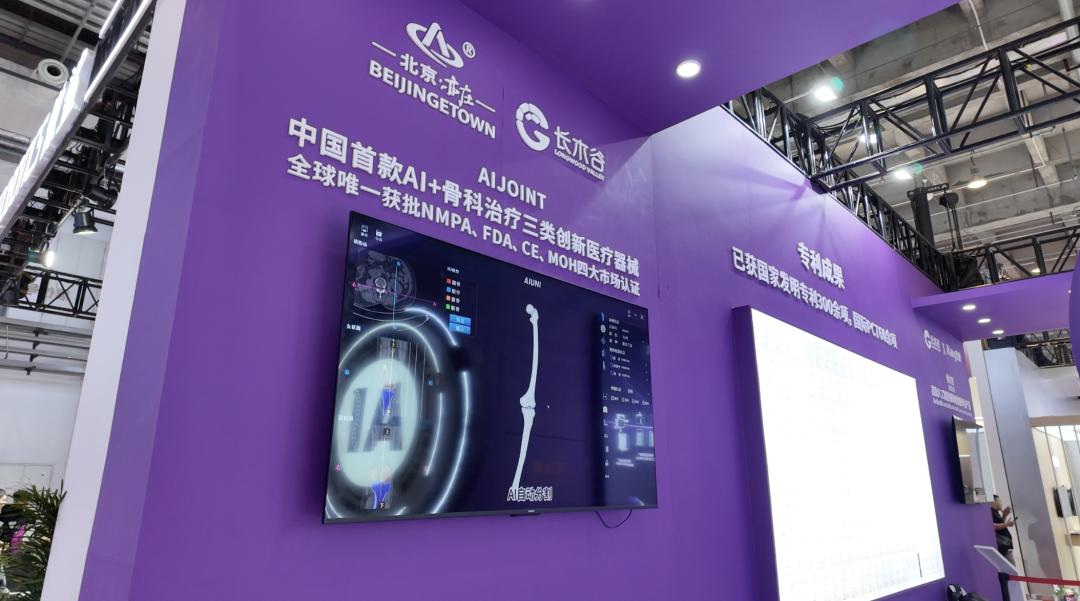

The specific needs in sub - fields such as medical surgical robots, agricultural robots, factory assembly lines, and health - care robots are also being steadily explored and developed by Chinese manufacturers.

But besides all the new things related to humanoid robots that people are interested in, there were also many veteran players in the robot industry at this exhibition. Their products may not be multi - functional, but as long as they can do one thing well, it's enough.

Compared with the emerging robots that are still in the growth stage, these industrial robots have been tested for decades, and their technology is quite mature. With their simple appearances, they have become an important part of various industrial production processes such as automotive manufacturing, material processing, and logistics transportation.

Some of these robots continue to improve in their traditional fields, while others want to keep up with the trend and try something new.

Take the large hydraulic robotic arm below, for example. It can easily lift heavy objects weighing hundreds of kilograms. It doesn't need to worry about battery life and can work continuously when plugged in. It's very common in production environments that require heavy - object handling or high - intensity palletizing.

In such relatively single - task scenarios, what different manufacturers and equipment compete for is how to take up less space, carry heavier objects, and improve efficiency. This involves the selection of high - strength materials and the optimization of structures such as joint design.

For