Aiming at domestic substitution and supplying electronic pastes in bulk to leading customers, "Yunhuang New Materials" has completed a pre-Series A financing of tens of millions of yuan | Exclusive from 36Kr

Text | Zhang Bingbing

Editor | A Zhi

36Kr learned that Haining Yunhuang New Materials Co., Ltd. (hereinafter referred to as "Yunhuang New Materials") recently announced the completion of a pre - A round of financing worth tens of millions of yuan. The investor is Yida Capital, and the funds will be mainly used to supplement the company's cash flow and expand the customer market.

Founded in 2022, "Yunhuang New Materials" is an emerging technology enterprise focusing on the R & D and production of high - end electronic pastes. It is committed to breaking the monopoly of foreign giants in the field of electronic functional materials. In the past two years, "Yunhuang New Materials" has focused on product R & D and customer testing. Nearly 60 products have been developed, covering application scenarios such as chip resistors, tantalum capacitors, radio frequency devices, and thick - film integrated circuits.

Currently, "Yunhuang New Materials" has achieved mass supply to a global leading customer group in the application of major chip electronic components, and will start supplying to a large - scale customer group by the end of 2024. In the first half of 2025, it will achieve tens of millions of sales and accelerate the commercialization process.

I. Starting from market demand, aiming for domestic substitution

As a key basic material in the field of electronic manufacturing, electronic paste is a paste - like composite material composed of functional powders (such as metal/ceramic particles), organic carriers (resins/solvents), and inorganic binders (such as inorganic oxides/glass powders). It is attached to the substrate through processes such as screen printing and roll coating, and forms a core layer with conductive, dielectric, or resistive functions after sintering. It is widely used in industries such as electronic components, radio frequency communication, and semiconductor electronic packaging, and is related to the innovation of terminal products such as AI, smartphones, new energy vehicles, and Internet of Things devices.

Different from the development path of scientific research entrepreneurs who first conduct technological innovation in the laboratory and then expand the customer base in the market, "Yunhuang New Materials" has positioned its products to solve customers' actual problems from the very beginning.

"Our core team has been in the electronic paste industry for more than a decade and has dealt with many customers in this industry. So we are very clear about the key problems that customers currently face in the market and the actual problems of products from mainstream foreign suppliers such as those from the United States and Japan." Cai Liangmin, the founder of "Yunhuang New Materials", gave an example. In the electronic component segment, "Yunhuang New Materials" has solved problems such as poor anti - static performance and negative temperature coefficient of traditional suppliers. The anti - static ability and load capacity of its products have been significantly improved, while also ensuring a high yield rate for customers' production. "We have improved other previously weak links without losing the original basic technical performance."

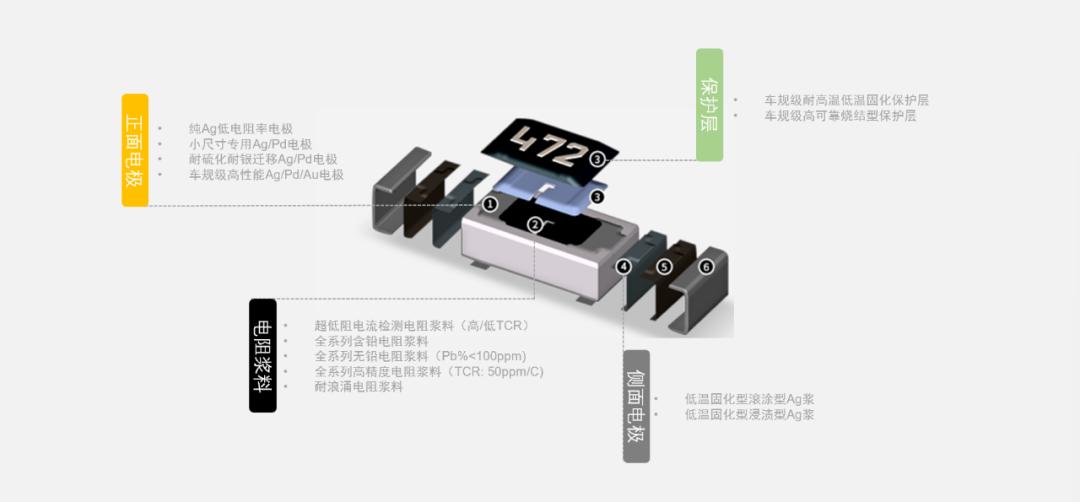

Product matrix of "Yunhuang New Materials"

In addition to product performance, response speed is another major pain point in the market. Cai Liangmin introduced that mainstream suppliers are relatively dominant. Usually, it takes several months from the time a customer's demand is put forward to the completion of internal discussions, and the response speed is relatively slow. "Yunhuang New Materials" has established a rapid response mechanism: it only takes 2 - 3 weeks from the time a customer's demand is put forward to the delivery of samples. Based on feedback, the product iteration cycle has been compressed to 1 - 2 weeks, improving the efficiency of supply chain collaboration.

"Unlike suppliers of terminal products such as mobile phones, tablets, and wearable devices, which have hundreds or thousands of customers, there are only about forty to fifty mainstream passive component manufacturers globally. Solving customers' core pain points is the quickest way to enter a highly concentrated market." Cai Liangmin introduced that "Yunhuang New Materials" will focus on the mid - to high - end market, aiming to replace suppliers from the United States and Japan and accelerate the process of domestic substitution of high - end electronic pastes.

II. Building technical barriers from raw materials to product systems

Domestic substitution is not easy. From the perspective of application scenarios, the domestic substitution rate of electronic pastes such as photovoltaic silver paste is already very high, but the domestic substitution rate of high - end electronic pastes used in applications such as automotive - grade chip resistors, tantalum capacitors, MLCCs, and radio frequency communication is generally less than 10%. Cai Liangmin analyzed that the technical barriers are reflected in three aspects:

Complexity of the product system: Systematic product R & D is very important for high - end electronic pastes dedicated to components. Taking chip resistors as an example, a compatible and adaptable system containing more than a dozen products needs to be built, and the entire series must pass customer - side verification before mass production can be introduced. Each application field of chip electronic components needs to build different systems based on a single application, and the complexity far exceeds that of the traditional photovoltaic field. This is the difference and complexity of the electronic component industry system.

High barriers in formula design: Formula design needs to consider the particle size selection, surface coating of various precious metal powders, the synthesis and post - treatment of precious metal compounds, and match various inorganic glass powders and oxides based on sintering and functional requirements. At the same time, the design of the organic system needs to be considered to meet the requirements of the customer - side manufacturing process. Any design deviation may lead to changes in product performance, and the R & D and design of the formula have extremely high barriers.

Technical bottlenecks in the dispersion process: The dispersion of electronic pastes has very strict requirements on the material feeding sequence and powder premixing, and the process parameters are also extremely sensitive. In the selection of raw materials, nano - sized palladium powder, silver - palladium powder, ruthenium powder with high specific surface area, and sub - micron silver powder are used. These small - particle - size powders are very likely to form granules or agglomerates during dispersion. To ensure the consistency of the overall product, uniform dispersion of powders in large - batch production of 50 - 100 kilograms needs to be achieved, and the powder morphology should not be damaged during the high - energy dispersion process.

In addition, there are many unpublicized process details in the industry, which require a team with long - term industry experience to innovate on the basis of experience. "The company does not simply follow the past traditional process flow and technology, but achieves a substantial breakthrough in cost reduction and efficiency improvement through self - developed innovative technologies." Cai Liangmin summarized.

In terms of customer expansion, after one and a half to two years of customer verification, "Yunhuang New Materials" has started to cooperate with leading companies in the industry and has begun mass supply. Currently, there are a total of 9 customers with formal monetary transactions, and more customers are being continuously introduced. In the first half of 2025, the sales orders exceeded tens of millions. Cai Liangmin expects that with the completion of theoretical verification and the acceleration of customer introduction, the business volume this year will reach tens of millions of scale.

According to the plan, "Yunhuang New Materials" will gradually improve the special application solutions in the fields of chip resistors, tantalum capacitors, and radio frequency, and simultaneously promote the product layout in fields such as chip inductors, thick - film integrated circuits, and MLCCs. It is expected to achieve full coverage of the three core businesses of resistors, capacitors, and inductors within 3 - 5 years.

36Kr Future Industries

"36Kr Future Industries" continuously focuses on urban development, industrial transformation, and the implementation of innovation and entrepreneurship projects. For media coverage, please contact wangfengzhi@36kr.com by email or scan the code to contact the author.

In addition, 36Kr officially launched the "36Kr Enterprise Investment Guide Newsletter" this year. Relying on its deep accumulation in the economic circle industrial cluster, regional key promotion plans, and investment promotion fields, 36Kr provides in - depth, detailed, timely, and exclusive comprehensive information services to provide government departments with efficient and accurate industrial project newsletters; it also helps project parties match industrial funds, connect with key contacts, and quickly integrate into the new industrial ecosystem.

This article is from the WeChat official account "36Kr Future Industries". Author: Zhang Bingbing, A Zhi. Republished by 36Kr with permission.