Betting on embodied intelligence, Midea's humanoid robots are accelerating their implementation: They will enter factories in May and be deployed in stores in the second half of the year.

Author | Huang Nan

Editor | Yuan Silai

In recent years, the traditional home appliance industry has reached a bottleneck in its development. The driving force for technological innovation is insufficient, and its product design and functional forms have reached a high level of maturity. Sales fluctuations mainly rely on the demand for equipment renewal or replacement in the existing market, and the scale of new users has stagnated.

In the highly competitive red ocean of the industry, it is an inevitable choice for leading enterprises to explore innovative product categories to break through the growth ceiling. Among them, embodied intelligence, which has the capabilities of environmental perception, autonomous decision - making, and physical interaction, has become the key direction for giants to break the deadlock in product iteration and reconstruct product competitiveness.

Since 2024, the popularity of embodied intelligence has continued to rise. Companies including Midea, Haier, and Hisense have successively announced their developments in the field of humanoid robots. Compared with startups, home appliance giants have the triple advantages of capital, talent, and application scenarios. Their participation has also brought more variables and vitality to the embodied intelligence track.

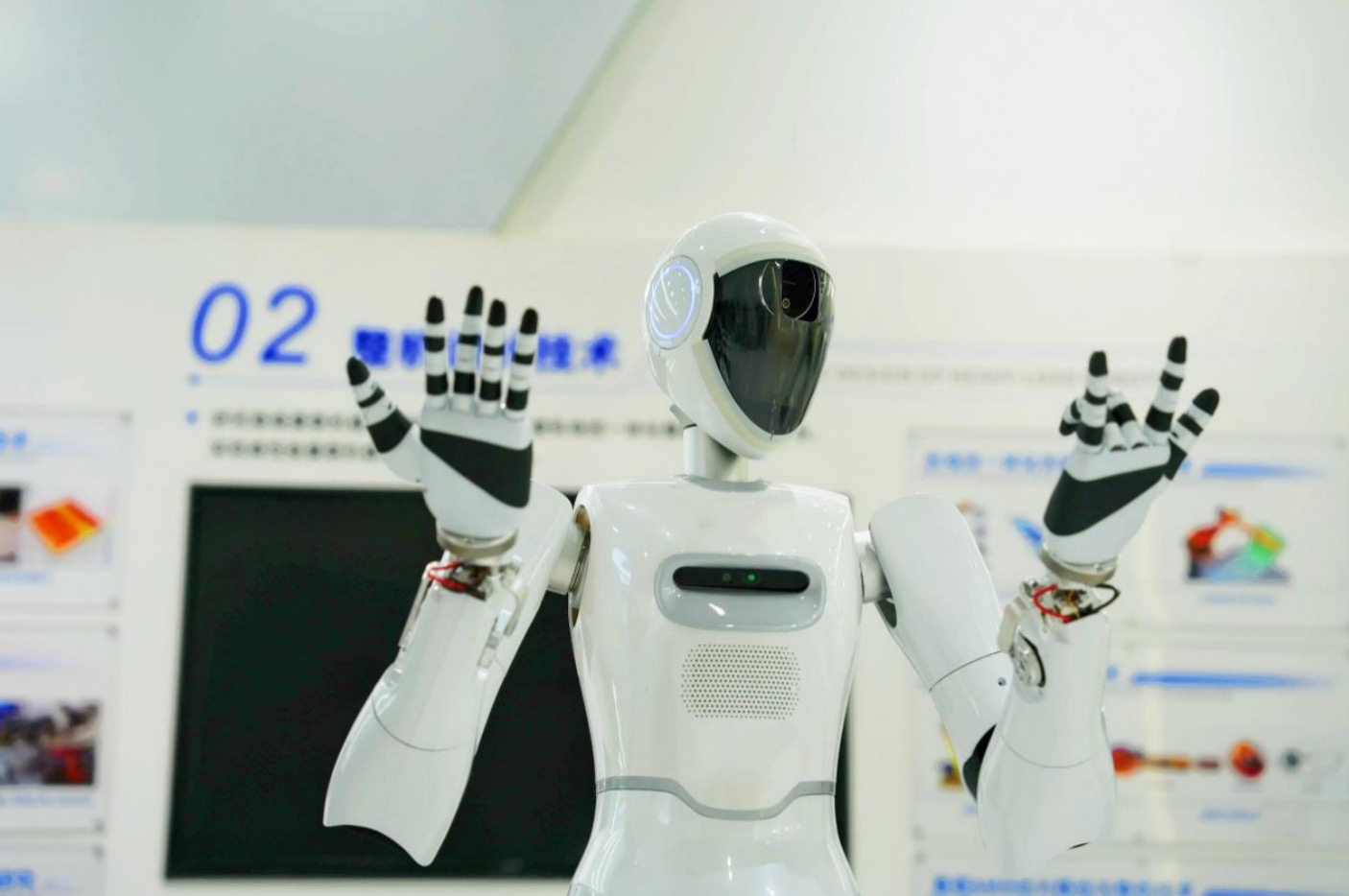

Now, Midea has established an innovation center for humanoid robots and recently unveiled its humanoid robot prototype for the first time. This robot can perform actions such as shaking hands, making a heart shape, dancing, handing over water, and screwing, and can understand voice commands and complete corresponding operations.

Midea's humanoid robot prototype

36Kr learned that Midea's layout in the field of embodied intelligence mainly covers two major directions: the research and development of humanoid robots and the innovation of home appliance robotization. Among them, humanoid robots include the whole robot and its core components, such as reducers, motors, sensors, and controllers, which are independently developed.

In terms of form, Midea's humanoid robots are divided into wheel - legged robots similar to human form and fully humanoid bipedal robots according to different usage scenarios.

For the factory field, Midea and its subsidiary KUKA Robotics have jointly developed a wheel - legged robot. Its chassis uses heavy - duty AGV technology, which makes the operation and movement more stable and can be seamlessly integrated into the factory's automated production line. This robot targets several application scenarios, such as the maintenance of factory equipment, the execution of fixed inspection tasks, including monitoring the oil status of equipment, the safety of fire - fighting facilities, the temperature, humidity, and noise level in the factory; and participating in standardized operation processes such as equipment loading and unloading and material handling.

In the past, Midea has built six lighthouse factories, mainly relying on industrial robots to promote the automation process of intelligent manufacturing. Official data shows that intelligent manufacturing has increased labor productivity by 28%, reduced unit costs by 14%, and shortened the order delivery cycle by 50%.

After introducing humanoid robots, Midea plans to further improve the flexibility and automation level of the manufacturing process. Taking the screw - screwing scenario as an example, the operating efficiency of the current humanoid robot is basically the same as that of production line workers. Through the design of differentiated product structures, Midea will continue to explore ways to improve production efficiency and optimize the total cost of ownership (TCO) in the factory.

For the retail store scenario, it is expected that Midea's humanoid robots will go to the store end in the second half of the year to perform tasks such as product introduction, gift distribution, coffee making and delivery, enhancing the in - store experience and attracting customers. In addition, the humanoid - like robot jointly developed by Midea Group and KUKA will start working in Midea's digital and intelligent factory in May this year.

Midea's humanoid robot prototype

Regarding the core home appliance business, Xi Wei, the person - in - charge of the humanoid robot innovation center at Midea's Central Research Institute, pointed out that the intelligentization and robotization of home appliances will be a major trend in the future home appliance industry.

The current industry development faces double bottlenecks. On the one hand, the space for iterative innovation focusing on performance parameters of traditional home appliances is becoming increasingly narrow. On the other hand, smart home technology has long centered around IOT technology to achieve device interconnection but has remained at the primary stage of "passively responding to commands", making it difficult to meet users' in - depth needs for active services.

"The essence of home appliance robotization is to transform the passive service of traditional home appliances into active service by introducing intelligent functions," Xi Wei said.

Xi Wei told 36Kr that the realization of home appliance robotization still faces three major technical challenges: first, the limitations of sensors, as the existing sensor types and accuracy are insufficient to build a complete home - scene perception network; second, the lack of edge computing power and reasoning ability, as complex decision - making logic needs to rely on the robot's brain or large - model technology to break through the bottleneck of local computing; in addition, there is the problem of scene adaptation of robot technology, as the mechanical structure design and motion control ability have not been deeply integrated into home appliance products.

In response to the above pain points, Midea also has a systematic technical layout. For example, it has released the Meiyan large - model at the algorithm level. In terms of intelligent agent technology, it is developing the technology platform HomeAgent (Meiban) to achieve the in - depth integration of natural language processing and home - scene decision - making. In terms of computing power infrastructure, according to different home scenarios and AI requirements, it offers a series of platforms with differentiated configurations of low, medium, and high computing power. Then, in terms of home appliance robotization technology, it promotes multi - modal perception technology and more intelligent, structured, and robotic - related designs, and launches the Homebots product matrix.

According to official data disclosed in February, the business revenue of Midea's robotics and automation segment has exceeded 30 billion yuan.

Xi Wei said that Midea plans to first introduce carriers with basic embodied intelligence into the home scene, promote the integration of home appliances and robotization technology, and launch a product matrix of embodied intelligent home appliances, such as embodied intelligent refrigerators, embodied intelligent ovens, and embodied intelligent vacuum cleaners. At the same time, based on the ultimate form of the future home ecosystem, on the basis of realizing the embodied intelligence of home appliances, new intelligent carriers such as humanoid - like or fully humanoid robots will be introduced to undertake various daily household tasks such as floor cleaning, clothes washing, item organization, and meal cooking.

When these humanoid robots and embodied intelligent home appliances work together, they will build an efficient, convenient, and intelligent future home ecosystem.