After over 30 years of exports, the impact of tariffs is limited. "Liaoning Northern Machinery" is accelerating its layout in the aerospace market.

Text | Liu Jingqiong

Editor | A Zhi

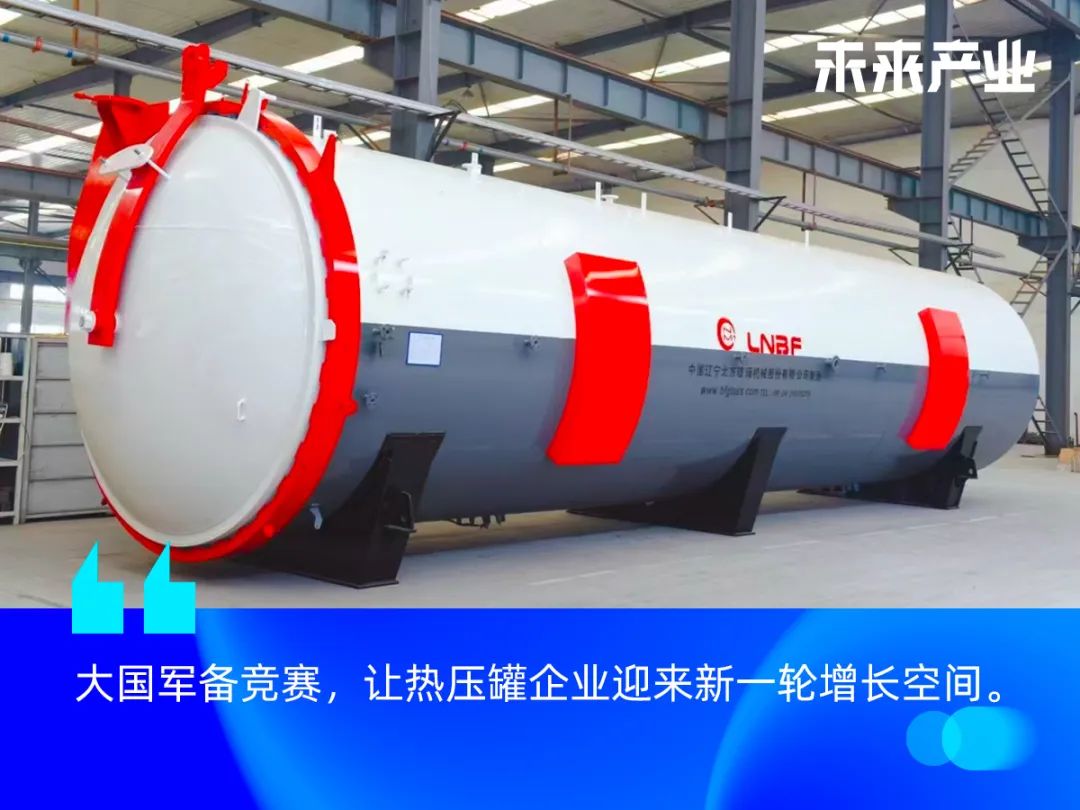

Cover Source | Provided by the enterprise

The continuous escalation of the US "reciprocal tariffs" has triggered a huge shock in the global supply chain. The tariff war is not only an economic means but also a strategic game to restructure the global industrial chain, which cannot end in the short term. However, China's countermeasures and the globalization journey of enterprises have not stagnated. The technology autonomy and market substitution strategies of suppliers at the supply chain end are highlighting the advantages of the system and regional depth.

Liaoning Northern Machinery Co., Ltd. (hereinafter referred to as "Liaoning Northern Machinery"), a "little giant" enterprise specializing in niche markets in Liaoning Province recently contacted by 36Kr Future Industry, used to mainly export autoclave equipment. Currently, it has shifted its overseas sales focus to regions other than the United States, so it has been less affected by this round of tariff shocks.

Liaoning Northern Machinery was founded in 1990 and is a supplier of composite material autoclaves. Its founder and chairman, Zhang Baocheng, is one of the first-generation entrepreneurs in the Chinese glass industry, along with Cao Dewang of Fuyao Group.

In the 1990s, the resin-based composite material industry in China was just starting. Manufacturers had to spend 3 million RMB to purchase autoclaves from Schott in Germany to complete the curing and molding of resin-based composite materials. Zhang Baocheng and his team keenly captured the business opportunity and started the road of self-developed domestic autoclaves, and gradually expanded their application fields to the composite material industry.

It is reported that currently, the market share of Liaoning Northern Machinery's autoclaves in the industry application has exceeded 80%. GKN in the UK, Saint-Gobain in France, Mitsubishi in Japan, PGG in the US, Fuyao, and Tie Mao are all its long-term cooperative customers. Against the background of the country's vigorous promotion of the aerospace industry, Liaoning Northern Machinery is also accelerating its layout in the aerospace market.

The Liaoning Northern autoclave used in the Russian factory of Fuyao Group

Independent control of R & D and manufacturing, products exported globally

An autoclave is a special equipment for the curing and molding of resin-based composite materials. Its internal environment is high-temperature and high-pressure. By precisely controlling the temperature, pressure, and vacuum degree, the curing and molding of high-performance composite material components are realized. Its core function is to meet the strict requirements for uniformity and compactness of resin-based composite materials during the molding process. It has now become the core production equipment in the fields of aerospace, automobile manufacturing, and new energy.

Like other high-end industrial equipment, autoclaves once relied heavily on imports. After decades of development, the domestic production of autoclaves has broken through multiple technical bottlenecks and gradually achieved domestic substitution. Various manufacturers have also emerged in the market, but few have the full-chain design and production capabilities. "Liaoning Northern Machinery is one of them, and we are also continuously promoting the intelligent upgrade of autoclaves," Zhang Hengze, the assistant to the chairman of Liaoning Northern Machinery, told 36Kr Future Industry.

In addition to 100% independent control of the full chain of autoclave design, production, and manufacturing, complete qualifications are another competitive advantage of Liaoning Northern Machinery. Currently, the company has obtained pressure vessel design and manufacturing license certificates from multiple overseas regions such as the US ASME, EU CE, Southeast Asian MOM, Russian EAC, and Malaysian DOSH. This is also an important prerequisite for its products to be exported to regions such as Europe, Southeast Asia, the Middle East, and Africa.

According to Zhang Hengze, Liaoning Northern Machinery is currently the autoclave manufacturing enterprise in China with the most export pressure vessel design and manufacturing qualifications. It has also obtained the Chinese A2-level pressure vessel design and manufacturing license certificate. "The A2-level qualification is the highest qualification that private enterprises can obtain. Our products can cover the range from 0 to 100 megapascals. In the autoclave industry, there are only 2 enterprises in the country that can independently master the entire process of design, production, and manufacturing and hold the A2 qualification at the same time, and we are one of them." Zhang Hengze added.

Currently, in addition to selling autoclaves to domestic and foreign enterprises, Liaoning Northern Machinery is also continuously undertaking the customized autoclave requirements for scientific research exploration and commercial delivery of in-system units.

The "reciprocal tariffs" reversely promote the growth of the domestic market, and the future focus is on aerospace

In the 1990s, Liaoning Northern Machinery produced its first autoclave equipment. Considering that the domestic civil composite material market was still in the cultivation stage at that time, the founding team made a strategy of "focusing on exports while developing the domestic market in parallel."

Currently, the products of Liaoning Northern Machinery have been sold to Russia, Japan, Europe, Southeast Asia, the Middle East, Africa, and other places, with an annual export volume of hundreds of units. In the domestic market during the same period, the company has also established long-term and stable cooperative relationships with some cutting-edge technology units, and its products have been widely used in the fields of military industry, aerospace, rail transit, construction, automobiles, and photovoltaics.

An autoclave with a diameter of 5 meters and a length of 24 meters provided for a Russian military industry unit

"Most of our orders come from overseas customers." Although affected by certain tariff shocks, Zhang Hengze is still optimistic about the company's export business. "Because the team shifted its overseas sales focus to other mainstream markets except the United States early on, and even if the new tariff costs are added, our autoclaves still have advantages in terms of quality, service, and cost-effectiveness."

If the trade war further escalates, the arms race between major powers will also speed up, and the development of the domestic aerospace market will be more rapid. This is also the business field that Liaoning Northern Machinery is currently focusing on expanding. In fact, meeting the requirements of "intelligence, high temperature and high pressure, and large size" for its production is also the future development trend of the autoclave industry.

Currently, the aerospace industry mostly uses autoclaves with a temperature of 250 degrees and a pressure of 1.2 megapascals to structure epoxy resin composite materials. With the increasing application of high-temperature-resistant thermoplastic composite materials such as PI (polyimide) and PEEK (polyetheretherketone) in the aerospace industry, according to the company's team prediction, when the domestic aerospace equipment is upgraded in the future, the industry's parameter requirements for domestic autoclaves will rise to more than 400 degrees and 4.5 megapascals, and the diameter of the container will also increase to 6 meters and above.

Facing the parameter requirements of greater pressure and larger size, how to control the temperature uniformity is a problem that domestic autoclave manufacturers must consider. Generally speaking, domestic enterprises have not caught up with German enterprises in temperature uniformity control. Liaoning Northern Machinery's upgrade plan is based on multiple self-developed technologies, connecting to Deepseek to repeatedly optimize and iterate the algorithm, and launching an exclusive multi-fan through-type autoclave. This product can solve the problem of decreased temperature uniformity when the autoclave is too long. The team's test data shows that for composite materials with special shapes, the temperature uniformity of this autoclave is significantly improved. It is reported that hundreds of such products have been running stably for 24 hours.

In terms of the size of workpieces, the largest general autoclave in the world is manufactured by Schott in Germany, with a specification of 9 meters in diameter and 60 meters in length, which can meet the production needs of super-large components such as rocket bodies and large aircraft fuselages. Currently, the effective diameter range of mainstream autoclaves in China is from 2 meters to 7 meters, and the length is mostly between 10 meters and 30 meters.

According to Zhang Hengze, Liaoning Northern Machinery has currently completed the self-developed design of an autoclave with a diameter of 8.5 meters and a length of 30 meters, which is suitable for the fields of aerospace, military industry, and automobiles. Deepening the service for the aerospace industry and accelerating the R & D innovation and manufacturing upgrade of domestic autoclaves will also promote domestic autoclave enterprises to enter a new growth cycle.