With its annual revenue growing sixfold, this metal 3D printing company secures nearly 100 million yuan in early-stage financing | Exclusive from 36Kr

Text | Lin Qingqing

Editor | Yuan Silai

36Kr learned that "Rongspeed Technology", a provider of metal wire feeding additive manufacturing equipment and services, has recently completed a new round of Pre - A++ financing worth tens of millions of RMB. This round of financing was invested by Ceyuan Ventures, and the funds will be mainly used for deepening the R & D of DED wire feeding technology, introducing core talents, and conducting multi - field scenario - based cooperation.

It is reported that in the past year, "Rongspeed Technology" has successively received three rounds of financing, with a total financing amount of nearly 100 million RMB. The investors include Ceyuan Ventures, Suzhou Xianze Laitai Investment, Qizhen Jiuzhi, as well as early investors Jihe Ventures and Mingshi Ventures. Yibai Capital serves as the long - term exclusive financial advisor.

Founded in 2020, "Rongspeed Technology" is a solution service provider focusing on the field of metal wire feeding additive manufacturing. It mainly focuses on three core business segments: additive manufacturing equipment, printing services, and additive manufacturing software. It independently develops laser wire feeding/arc additive manufacturing equipment, provides DED additive manufacturing software such as process monitoring and path planning, and supports printing services for more than 30 types of metal materials to meet the ultra - automation needs of industrial production.

Currently, the metal 3D printing industry is gradually emerging. Tianfeng Securities pointed out that metal additive manufacturing technology will become the mainstream trend in the future. In particular, the DED (Directed Energy Deposition) wire feeding technology, as an important branch, is regarded as a key technology for the upgrading of industrial manufacturing. According to statistics from the Zhongyan Puhua Industrial Research Institute, the market scale of China's metal 3D printing equipment reached 3.171 billion RMB in 2023, and it is expected to exceed 9.5 billion RMB by 2030. The global metal additive manufacturing market is expected to grow from 4.7 billion US dollars in 2024 to nearly 60 billion US dollars in 2034.

However, the iteration of the core DED wire feeding equipment in China is slow, and the popularization of technology application is low. The market is still in the initial growth stage. It can be said that there are few companies engaged in this technology globally, and only a few in China.

The existing pain points in the industry mainly lie in the high cost, long cycle, and serious material waste of traditional manufacturing processes in the manufacturing of medium - and large - sized components. The existing 3D printing technologies also have difficulty meeting the market demand in terms of cost, accuracy, and speed.

Xu Fangda, the general manager of "Rongspeed Technology", told 36Kr that he witnessed and experienced the original technology accumulation stage of the DED wire feeding technology from the prototype to industrialization abroad, and his doctoral thesis was also focused on super - large - scale 3D printing. "The market for medium - and large - sized components mainly relies on casting and forging processes, which take a long time. 3D printing technology can significantly reduce the time, lower the cost, and improve the manufacturing process."

Based on this, the "Rongspeed Technology" team initially focused on two major directions: wire arc additive manufacturing (WAAM) and wire laser additive manufacturing (WLAM), and launched a domestic metal additive manufacturing solution. The main products developed include the laser wire feeding additive manufacturing platform Laser One, Robo L1, and the arc additive manufacturing equipment S - T - A - R series.

Among them, Laser One is currently the only multi - laser coaxial wire feeding additive manufacturing equipment in China that meets the mass - production standards, successfully filling the market gap for WLAM additive manufacturing equipment in China. It can be used for printing requirements with smaller sizes and higher precision. The S - T - A - R series of equipment performs excellently in the mass - production of large - scale industrial molds and has the production capacity for large - scale industrial molds such as propellers, ring - vertical rib components, and valve bodies.

The multi - laser coaxial wire feeding additive manufacturing technology VEAM of "Rongspeed Technology"

In terms of the core technology route, it is reported that the self - developed multi - laser coaxial wire feeding technology VEAM of "Rongspeed Technology" has successfully overcome the difficulties of domestic laser wire feeding additive manufacturing technology. This technology uses a fully self - developed six - laser coaxial wire feeding 3D printing system, and is equipped with a Matrix array laser controller to achieve independent control of multiple beams, ensuring more uniform energy distribution. It has the advantages of high precision (roughness up to 5μm), high efficiency (deposition rate of 1kg/h), and low cost. Based on the VEAM technology, the self - developed super - integrated laser wire feeding additive manufacturing system L1 Lite is composed of a multi - laser drive box, a laser deposition head, and a push - pull wire system module, realizing the integration of five systems of water, gas, wire, light, and electricity, and improving the comprehensive performance of the system.

In addition, 36Kr learned that the "Rongspeed Technology" team has also comprehensively improved the printing quality and automation level of the platform by optimizing each subsystem, and self - developed a software management system AMtwin integrating functions such as process monitoring, path planning, and simulation. It is worth mentioning that the "Rongspeed Technology" team can achieve all - round monitoring and automatic correction of key parameters in the printing process in terms of full - stack engineering capabilities, ensuring the traceability of the quality of the entire process.

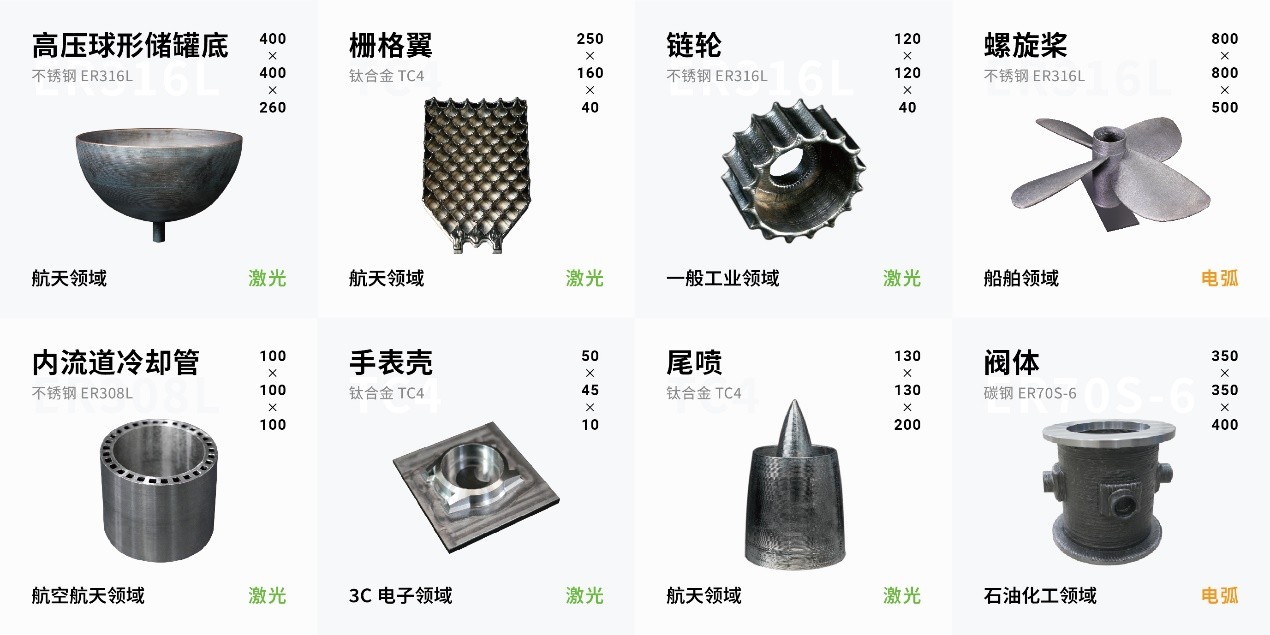

In addition, the company has delivered more than 600 DED wire feeding printed products in total, with a total delivery weight of more than 12,000 kg. It has more than 20 sets of wire feeding additive manufacturing platforms, supports printing of more than 30 types of metal materials, and will continue to launch new products this year.

Some finished products of metal 3D printing by "Rongspeed Technology"

Xu Fangda said, "Next, we will focus on two major directions. One is to launch a new generation of laser wire feeding equipment to break through the limits of deposition efficiency and accuracy. The other is to cooperate with leading customers to explore more application scenarios of DED technology in emerging fields such as construction and new energy."

In terms of the team, Xu Fangda, the general manager of "Rongspeed Technology", graduated from Harbin Institute of Technology with a bachelor's degree, and from the University of Bath in the UK with a master's and a doctoral degree. He has worked in several world - renowned research institutes and technology companies, with rich industrial R & D experience. Most of the core team members also come from well - known universities and enterprises at home and abroad, such as Harbin Institute of Technology, Beckhoff in Germany, Inovance Technology, SAIC, and Geely.