Breaking through the difficulties of high price and low production capacity of commercial rockets, "Yushi Space" has completed tens of millions of yuan in angel round financing | 36Kr exclusive.

Written by Liu Jingqiong

Edited by A Zhi

36Kr has learned that Beijing Yushi Space Aerospace Technology Co., Ltd. (hereinafter referred to as "Yushi Space") recently announced the completion of a tens of millions of yuan angel round of financing. This round of financing is led by Linge Venture Capital, with Yingtan Aerospace and Tsinghua Alumni Seed Fund following the investment. The funds raised will be used for the company's rocket product research and development.

"Yushi Space" was established in 2024 and is currently focused on the research and development and manufacturing of large-capacity, low-cost, and fast-reusable liquid rockets. It is currently "the only team in China that adopts a stainless steel rocket + 'chopstick' capture arm recovery solution". The company is committed to breaking the current development dilemma of high prices and low production capacity of commercial rockets, providing customers with the lowest-cost fast-reusable liquid rockets. Its core product, the AS-1 rocket, is in the production stage of the common-bottom tank of the second stage.

The founder and CEO of "Yushi Space", Dr. Tang Wen, said that rockets belong to the category of high-end manufacturing. The ultimate goal of development is to achieve extreme low cost and high efficiency, and all new technology explorations serve these two purposes. The company's products adopt a technical route of stainless steel rocket body structure + liquid oxygen methane power + "chopstick" capture arm recovery technology to create the lowest-cost large-scale liquid reusable rocket in China to serve the future demand for massive satellite networking.

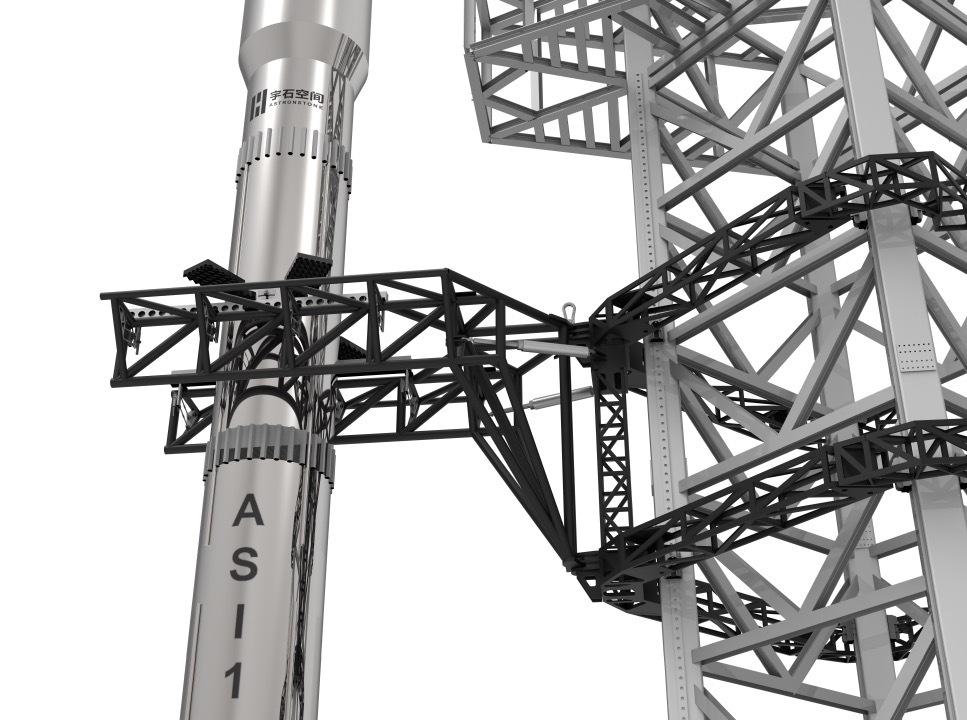

Rendering of Yushi Space AS-1 Rocket

Technical Combo to Solve the 'Final' Problem of Commercial Rockets

In 2023, Xingwang Group and Yuanxin Satellite officially began to carry out satellite networking layout. The two have a comprehensive plan to launch nearly 30,000 satellites. The market scale of hundreds of billions and the huge capacity gap have given commercial rocket companies a once-in-a-decade opportunity.

"The final outcome of commercial rockets is to solve the problems of reusability and high cost. In the future, the commercial rocket company with the lower cost will win the final victory." "Yushi Space" chooses to break the situation with the technical route of stainless steel rocket body structure + liquid oxygen methane power + "chopstick" capture arm recovery.

Traditional disposable rockets dominate the market, and this "high cost and low reusability" model is difficult to meet the needs of the rapid iteration of the current domestic commercial aerospace. In Tang Wen's design, the "Yushi Space" AS-1 rocket will be a low-cost and reusable product, and the key to low cost lies in the use of stainless steel as the rocket body material. Tang Wen introduced, "The traditional rocket body structure mostly uses aluminum alloy material, and the price of the stainless steel material we use is only 1/4 of that of aluminum alloy."

Although stainless steel is superior to aluminum alloy in high temperature resistance and reusability, the doubt that its weight may affect the rocket's carrying capacity has always existed. The solution of the Yushi team is, "Under the condition of ensuring that the structure bears the same load, we first use a thinner stainless steel material; secondly, through the integrated design of the power structure, we seamlessly connect the structural components with different functions to form a complete and continuous force-bearing system, reducing the gap and connection points between the components, thereby reducing the structural weight." According to the design and measured data of the Yushi team: The weight of the rocket structure made of stainless steel material can be basically the same as that of aluminum alloy. Considering the advantages of stainless steel in manufacturing and material costs, under the condition of reuse, it can be said that the use of stainless steel material is the most significant means to reduce the cost of the rocket structure.

In terms of the power solution, different from the mainstream power solution using liquid oxygen kerosene, "Yushi Space" chooses liquid oxygen methane. Tang Wen believes that "The liquid oxygen methane engine solves the problem of easy coking and carbon deposition of the liquid oxygen kerosene engine, which can extend the service life, reduce the maintenance frequency, and is more suitable for the reuse of rockets. The cost of methane is relatively low, and the combustion process of methane and liquid oxygen is stable, which is easier to improve the reliability of the engine."

Considering the rapid reuse of rockets, in terms of the recovery method, "Yushi Space" abandons the traditional landing leg solution and adopts the "chopstick" capture arm recovery solution. "This makes the rocket structure simple, easier to maintain, and has a greater carrying capacity (the rocket's carrying capacity is increased by more than 15%), and the rocket using the chopstick capture arm recovery has more advantages in cost." Tang Wen added. In fact, the members of the "Yushi Space" team have been deeply engaged in the research of recovery landing point control technology since 2017, and the flight test verification has been completed in 2019.

The combination of the stainless steel rocket body and the liquid oxygen methane dual low-temperature power advantage can better exert the performance advantage of the stainless steel structure under low-temperature conditions. At the same time, the stainless steel rocket and the chopstick recovery technology cooperate with each other. The former provides an economic basis for the rapid iteration of the recovery technology, and the latter further consolidates the low-cost advantage. This set of technical combos is the route choice that "Yushi Space" believes is the closest to the final outcome of commercial rockets at present.

Aiming at Large-Diameter Liquid Rockets to Accelerate Technology Implementation

Rockets are used to launch satellites, and the demand in the satellite market will inversely affect product design. The scale of China's low-orbit satellite communication constellation is close to 30,000, and the networking construction will only begin in the second half of 2024. In order to meet the networking needs, at least about 7 tons of carrying capacity is required for one rocket to launch multiple satellites, and small solid rockets are difficult to achieve such a large carrying capacity.

Therefore, since its establishment, "Yushi Space" has targeted the largest market demand for commercial rockets and plans to launch its first product, the AS-1, as a large-diameter liquid rocket. It is reported that the AS-1 rocket has a diameter of 4.2 meters, a one-time carrying capacity of more than 15 tons, and a recovery carrying capacity of more than 10 tons; the one-time launch cost can be as low as 20,000 yuan/kg, and the recovery launch unit price is 10,000 yuan/kg, which is lower than the market average level. Currently, domestic rockets have not yet achieved recovery and reuse. The recovery and reuse cycle of the first stage of the rocket with the landing leg solution is 30 days, while the AS-1 rocket that "Yushi Space" is about to launch can shorten the reuse cycle of the first stage to 10 days, while taking into account the characteristics of high carrying capacity, low launch cost, and rapid reuse.

When it comes to commercialization layout, Tang Wen introduced the "To B Foundation, To G Breakthrough, To C Potential Accumulation" stepped development strategy that "Yushi Space" plans to implement. The ToB market is the main battlefield. Yushi will provide "chartered" launch services for low-orbit satellite Internet constellation enterprises, and this type of enterprise requires a normalized launch capability of about 100 rockets per year; at the same time, Yushi also provides "chartered + shared" mixed launch services for remote sensing, communication satellite, and detector enterprises. The ToG market is the long-term strategic fulcrum. Yushi hopes to give full play to the advantages of technical costs and provide solutions for national engineering projects. The ToC market is the future ecological entrance with great growth potential.

The team is another highlight. "Yushi Space" has an entire team that is the first in the country to realize the technical route of stainless steel rockets. The team has a composite background of liquid rockets in Chinese and foreign aerospace institutes and commercial rocket companies, as well as aerospace robots, including top talents in the fields of rocket overall, structure, power, and recovery. Dr. Tang Wen firmly believes that "The future commercial aerospace must be inclusive, attracting a large number of top talents in physics, mechanics, materials science, and robotics to cross-border integrate. The company's co-founder team with me as the core will adopt an open attitude to attract talents from China's advantageous high-end manufacturing industry and guide the transformation to commercial aerospace through the training of the talent echelon."

The founder and CEO, Dr. Tang Wen, graduated from the School of Aerospace Engineering, Tsinghua University, with 14 years of experience in liquid rocket power and structure. He has achieved the first stainless steel liquid oxygen methane rocket prototype and static ignition in China. Earlier, Dr. Tang Wen has fully experienced the rocket development of the CZ-5, the largest liquid rocket with the largest carrying capacity in China, and the CZ-7, the liquid rocket for the cargo of the Chinese Space Station, within the Aerospace Research Institute No.1. The CTO, Dr. Tian Jichao, graduated from the School of Astronautics, Harbin Institute of Technology, with 15 years of experience in overall liquid rocket work.

Unlike traditional start-up companies, "Yushi Space" has an entire entrepreneurial team. Based on the past technical, resource, and experience reserves and high coordination, it has a clear and reliable overall design plan and has begun to carry out the production and testing of the rocket structure. It is reported that the second-stage tank of its core product, the AS-1 rocket, will be completed by the end of the month, which will also be the fastest efficiency for a private rocket company from establishment to the production of large structural components. Before the end of the year, the company also plans to complete the second-stage static ignition, the first-stage structure manufacturing of the first flight rocket, and the ground verification test of the "chopstick" capture system.