Alle wollen liefern, wer liefert tatsächlich? Eine Frage mit drei Fragezeichen.

The number of exhibitor companies has increased from 800 to 1,200, representing a year-on-year growth of 50%. A total of 14.81 billion yuan was financed, and 19,000 robots and related products were sold. Humanoid robots have taken the "C-position" for the first time, reaching a share of 42%, surpassing the share of industrial robots (38%). The remaining 20% is accounted for by service robots, special robots, and other categories, all of which showcase their strengths in the "New Force" camp.

On August 12, the 2025 World Robot Conference ended. This year, the Yizhuang National Exhibition Center was significantly more crowded than last year.

Behind the excitement and noise lies the common psychological state of companies – caution, anxiety, and the hard-to-express "delivery pressure." Today, the capital market is no longer easily impressed by the word "anthropomorphic," and customers are no longer interested in hearing how powerful the model is and how impressive the parameters are. Instead, they are interested in whether this robot can be delivered on time and operate reliably on their production lines.

In other words, after the rapid technological demonstrations, robot brands are facing a more realistic test.

Therefore, we can break down the "delivery" into three quantifiable questions:

Order processing: Who has signed purchase orders (PO) in hand?

Application scenario processing: Can the robot operate 24/7 in a real working environment?

Financial processing: Is the robot revenue of listed companies separately reported in the financial statements, and what is the proportion?

Let's look at the industry developments revealed by this year's World Robot Conference together with these three questions.

Who gets the orders?

At this year's conference, the commercial progress of humanoid robots was in the spotlight. Several leading companies publicly announced their order successes, attracting the industry's attention.

According to statistics, by early August, Yushu Technology had won 68 orders, Unitree Robotics had won 16, and Zhipu Robotics had won 9 projects so far. The number of projects these companies have won this year is close to or exceeds that of the entire last year.

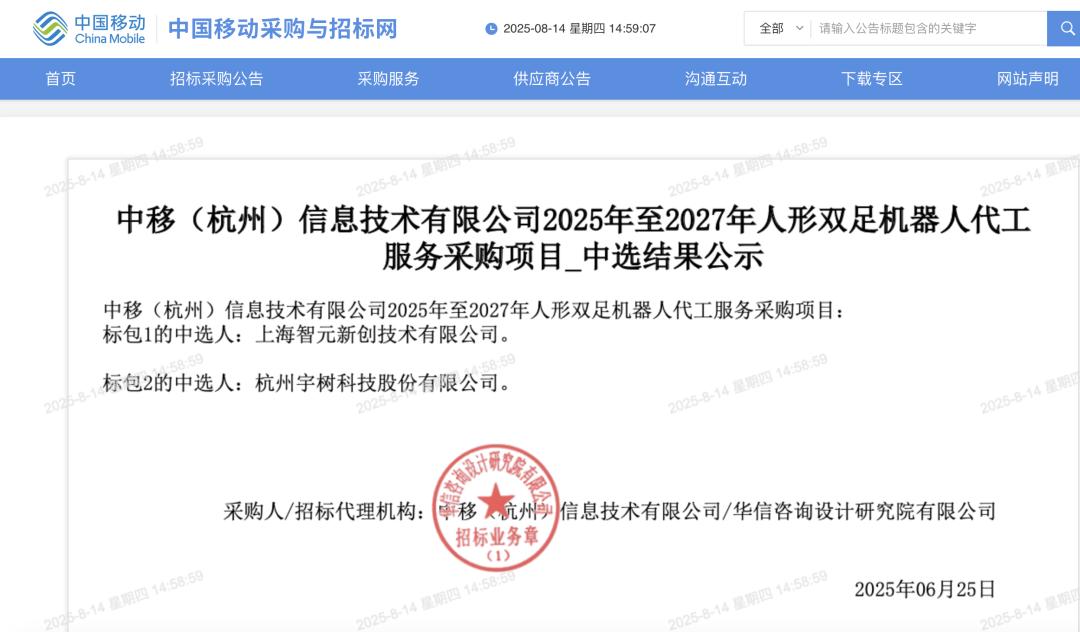

In mid-July, China Mobile launched a procurement project for humanoid robot products worth a total of 124 million yuan. Finally, Zhipu Robotics and Yushu Technology were selected as the contractors. Zhipu Robotics won an order worth 78 million yuan and is supposed to deliver 200 sets of full-size bipedal humanoid robots, with the tax-included unit price being about 390,000 yuan. Yushu Technology won an order worth 46.05 million yuan and is supposed to deliver 200 small humanoid robots, with the tax-included unit price being about 230,000 yuan. Thus, the previous record for the largest single order volume of humanoid robots in China was set.

According to the information made public on China Mobile's procurement and bidding platform, Zhipu Robotics and Yushu Technology have won the project "Order service for the manufacturing of bipedal humanoid robots of China Mobile (Hangzhou) Information Technology Co., Ltd. from 2025 to 2027." The robots procured here will be mainly used for research, inspection, and service applications.

Recently, the established humanoid robot company Unitree Robotics also won a large procurement order for robot equipment worth a total of 90.5115 million yuan, breaking the previous industry record. Dongfeng Motor recently signed a contract with Unitree Robotics and plans to test Unitree's humanoid robots in its factory. The new automaker NIO has also tested Unitree Robotics' Walker S humanoid robot in its factory.

According to the "Announcement on the awarding of the robot equipment procurement project" published on the public bidding and awarding platform in China on July 18, Unitree Technology won the robot equipment procurement project of Miyi (Shanghai) Automotive Technology Co., Ltd. (abbreviated as "Miyi") worth 90.5115 million yuan.

Jiao Jichao, the vice-president of Unitree Robotics, revealed at the WRC conference that the company will deliver about 500 industrial humanoid robots this year, which will be mainly used for moving, sorting, and quality control in industrial scenarios. The customers are mainly automakers, 3C, and semiconductor companies.

Among the new players, Songyan Power has shown particularly outstanding performance. In July this year, it announced that it would mass-produce and deliver 105 humanoid robots in a month, making it the first Chinese company to exceed the mark of 100 delivered units in a month. The company "made a name for itself" at the beginning of the year through a humanoid robot marathon race. One month after the race, it received over 2,000 order offers with a contract value of over 100 million yuan. Thus, after Yushu Technology, Songyan Power is the second Chinese company to reach the threshold of "1,000 sold units" and is firmly in the forefront of commercial development. It is known that currently, nearly 100 Zhipu Expedition A2 - W robots are installed in the Fuling Precision Factory and are actually "working."

It can be said that today, it is clear "who has the orders," from the concentrated procurement of state giants to the mass delivery of startups.

Of course, "order processing" is not only carried out for humanoid robots. The leading players in the service robot field also have impressive results to show.

Li Tong, the founder of Keenon Robotics, recently revealed that the company has installed a total of over 100,000 robots of all kinds. Since the beginning of this year, the order development has been rapid, especially in the overseas market, where the order volume has increased by at least 50% compared to last year. Keenon's strategy is pragmatic - "let the orders precede the technology": It doesn't limit itself to whether they are industrial, service-oriented, or medical robots, but instead first selects "easy jobs" that can be achieved with the current technology. This pragmatic strategy has helped them quickly generate a large number of orders and has also proven that there is indeed an urgent need in certain niche scenarios.

On an international level, the race for order processing is a global phenomenon.

Tesla has been highly visible in the public since the announcement of the Optimus humanoid robot project. Elon Musk claims that thousands of robots will be mass-produced in 2025 and that production will increase exponentially in the following years. European automotive giants also don't want to be left behind: At the beginning of this year, BMW entered into a partnership with the humanoid robot startup Figure and plans to test the company's robots in its factory in South Carolina.

It is predictable that obtaining the "real" orders is only the first step. Whether these orders can be successfully fulfilled and the robots can be delivered on time will be the touchstone to test the strength of the companies.

The "application scenario delivery" is the real test

So far, many of the robots delivered this year are mainly operating in relatively favorable environments. According to statistics, the current humanoid robot orders mainly fall into the area of interactive services such as performances, reception, and guiding in exhibitions. Clearly, there is still a long way to go before robots are directly involved in complex industrial production tasks. Many robots are more like "showpieces" or attention-grabbers: They greet customers in branches, work as guides in tourist areas, or dance and show martial arts at conferences.

Compared with the situation last year when there were "many humanoid robots but few functioning" in the exhibition hall, today almost every manufacturer can report on the actual application scenarios of its robots. The transition from technology demonstration to mass production has begun. However, most of these application scenarios are still at the level of non-core demonstrations and are not urgently needed jobs in actual production.

Of course, the situation is changing. Some robots are finally starting the "7 - day - 24 - hour" test.

The order project won by Unitree Robotics from an automotive technology company requires that its industrial humanoid robots be integrated into the production line and take on tasks such as moving components. At the conference, Unitree also presented five humanoid robots. The Walker S2 relies on "automatic hot - swapping of batteries," and the S1 has carried out sorting and collaborative moving on a simulated production line, demonstrating the working model of "auxiliary robot + main robot." The company has publicly set the goal of "1,000 delivered units" for the whole year and reported an order worth nearly 100 million yuan. Obviously, it wants to be the first to complete the "delivery." However, insiders revealed that the current experiments in industrial scenarios are still "application demonstrations at local workplaces" - in other words, it is still just a decoration and not a decisive player on the production line.

The procurement project taken over by Zhipu Robotics and Yushu Technology from China Mobile focuses more on public service scenarios. The customized bipedal robots will be used in the branches of the telecommunications provider to greet customers. Although these scenarios are not rigid industrial workplaces, they still place real requirements on the stability, recognition ability, and responsiveness of the robots. Also, it is known that currently, nearly 100 Zhipu Expedition A2 - W robots are installed in the Fuling Precision Factory and are actually "working."

Outside the industrial field, the humanoid and quadruped robots of Yushu Technology are also gradually opening the window for the "7 - day - 24 - hour operation" test. Its products have been used in university laboratories such as Sun Yat - sen University and Shenzhen University for research and teaching. They have also been procured by water supply companies and science museums for security inspections and public presentations. Overseas, Yushu has also signed a procurement contract with an American warehousing and logistics company and will deliver hundreds of quadruped robots to it for warehouse inspections. These robot dogs are designed for long - term autonomous patrols and are naturally suitable for high - frequency and demanding tasks.

In addition, Yinhe General integrates its wheeled robots into "unmanned pharmacies" and lets them actually work there. At the same time, feasibility studies are being carried out in scenarios such as power inspections and factory logistics. The wheel - legged robots of Seer Intelligence automatically transported goods in a simulated conveyor belt environment at the conference without remote control, showing the stability and efficiency of a "silent worker." The "Xiaomai" robot of Magic Atom, which is only responsible for ringing the bell and announcing the time in meetings, is praised by the audience as the robot that "acts most like a work colleague" because it is "punctual, stable, and unobtrusive."

DJI continues its consistent strategy. Its industrial drones and ground robots are distributed in several exhibition areas and perform tasks such as high - altitude inspection, AI recognition, and autonomous work. They don't take the limelight but are always reliable.

It can be said that in many areas outside the industry, the "continuous operation of robots" is turning from vision into reality.

Let's look at the global development: Figure AI was not present at the conference, but its company value is already approaching 4 billion US dollars. It has a partnership... (The text seems to be incomplete here.)