With an academician on board and a professor from Shanghai Jiao Tong University as an entrepreneur, this company is accelerating the leapfrog development of domestic welding and joining process equipment.

Author | Wu Ruoyu

Editor | Peng Xiaoqiu

Yingke has learned that Shanghai Zhirong Industrial Equipment Co., Ltd. (hereinafter referred to as "Zhirong Equipment") has completed a total of tens of millions of yuan in seed and angel rounds of financing. The angel round was led by Zhongying Venture Capital. The financing funds will be mainly used for new product R & D and market expansion.

Zhirong Equipment focuses on the fields of industrial welding, new connection processes, and intelligent equipment, and continuously promotes the R & D and production of high-performance connection technologies, quality control equipment, and software. The self-developed friction self-piercing riveting (F-SPR), resistance riveting welding (RRW) technical equipment, and intelligent resistance spot welding quality monitoring equipment of the company effectively solve the problems of domestic lightweight material connection and online monitoring and control of the quality of spot weld joints. The products are mainly used in fields such as automobile body-in-white, power batteries, aerospace, rail transit, and low-voltage electrical appliances.

The establishment of Zhirong Equipment is inseparable from the Thin Plate Structure Manufacturing Research Institute of the School of Mechanical Engineering at Shanghai Jiao Tong University. In 1996, Academician Lin Zhongqin founded this institute. Facing the major national needs and the main economic battlefield, a series of "industry-university-research-application" technological innovations and incubation transformations of manufacturing processes and equipment for metal and non-metal thin plate materials have been carried out, and now several enterprises have been incubated. Zhirong Equipment originated from the Advanced Welding and Connection Research Group of the institute, focusing on the R & D of innovative welding and connection process equipment and software for thin plate structures. Later, with the support of the Shanghai Intelligent Manufacturing Functional Platform, after a series of business incubations, it was officially established in 2019.

Against the background of carbon neutrality, the development trend of structural lightweighting of traditional vehicles has become increasingly clear. Taking new energy vehicles as an example, through the lightweight structure transformation, energy consumption and emissions can be effectively reduced, and the cruising range can be extended at the same time. Research shows that for every 100 kg reduction in vehicle body weight, the fuel consumption of traditional fuel vehicles per 100 kilometers can be reduced by 0.4 L, and the cruising range of new energy vehicles can be increased by 10%. The automotive lightweight technology has also been included in "Made in China 2025" and has become a key direction for industrial development.

However, the application of lightweight technology must break through the world problem of connecting lightweight brittle materials and heterogeneous material hybrid structures. Due to the poor weldability and connectability of lightweight materials and the different physical and chemical properties of different materials, traditional connection process manufacturing technologies are facing great challenges and it is difficult to meet industrial needs.

Looking at the development situation abroad, even though European and American manufacturers started earlier, key connection technologies such as self-piercing riveting (SPR), flow drill screwing (FDS), and blind riveting have been maturely applied in the thin-walled structures of vehicles. However, with the composite application of lightweight materials such as aluminum alloy, high-strength steel, cast aluminum, magnesium alloy, and thermoplastic/thermosetting composites, these traditional processes also have pain points such as serious riveting cracking, poor airtightness, inability to connect heterogeneous materials, and low process efficiency.

Therefore, the market urgently needs to solve the problem of connection technology adaptation when new materials such as cast aluminum, aluminum plates, aluminum profiles, magnesium alloys, and carbon fiber composites are applied on a large scale in high-end precision manufacturing fields such as automobiles, rail transit, and aerospace. At the same time, domestic enterprises can also take this opportunity to get rid of their dependence on imported equipment or imitation of imported equipment, and truly achieve a leapfrog development of domestic welding and connection equipment.

Zhirong Equipment has independently developed a new F-SPR (Friction-SPR) process and equipment to address the pain points of mixed connection of new materials and multi-materials. It balances the contradiction between the low ductility nature of materials and the large deformation requirements of riveting, solves the problem of riveting cracking of low-ductility light alloys, and realizes damage-free, crack-free, and defect-free connection of multi-materials. The process technology and equipment have complete independent intellectual property rights.

Self-piercing friction riveting equipment and rivets

In terms of market verification, Zhirong Equipment has reached a cooperation with leading power battery manufacturers to jointly research a new connection process for power battery trays of new energy vehicles. The preliminary product proofing and testing have been completed, and it is about to enter the mass production stage. Regarding the application of lightweight material connection in body-in-white, the company has also established connections with new energy vehicle manufacturers. In the aerospace field, the company has carried out proofing tests with COMAC to promote the on-board application of the technology. In the rail transit field, it has completed a fixed-point cooperation with CRRC system enterprises and is expected to apply the process in the new generation of lightweight rail transit products, which will realize the replacement of the traditional blind riveting process by Zhirong Equipment's self-developed process equipment.

Principle and application scenarios of self-piercing friction riveting process

"For example, the traditional blind riveting process for connecting aluminum alloys requires pre-drilling holes, removing debris, and then manual blind riveting. Not only is the sealing performance insufficient, but there are also risks of poor joint appearance and corrosion. Our process equipment can effectively solve the problems of double-sided protrusion and corrosion of blind riveting joints, and there is no need for pre-drilling holes. The two steps of heating penetration and riveting welding are completed simultaneously, shortening the process time of one spot weld from 3 - 5 minutes to less than 3 seconds." Lei Haiyang, the general manager of Zhirong Equipment, added.

Zhirong Equipment has also extended its business to the scenario of intelligent detection of spot weld quality. The automation rate of the existing welding workshops in the automotive industry is very high, but the post-weld inspection still relies on manual off-line sampling for a series of actions such as chisel inspection, ultrasonic inspection, or destructive inspection, which is very backward in terms of industrialization efficiency and cost control. Moreover, the steel body-in-white of automobiles is mainly made by welding stamped parts made of galvanized steel sheets or hot-formed steel sheets. Resistance spot welding, as the most important connection method in the steel body-in-white, accounts for more than 80% of the vehicle's connection processes. Manual sampling inspection of spot weld quality is inefficient, and the accuracy and coverage are insufficient. In addition, the widespread application of high-strength steel materials such as galvanized sheets and hot-formed steel in the body-in-white has led to serious welding spatter, resulting in a harsh environment in the welding workshop and manual grinding after parts welding, which is seriously incompatible with industrial development.

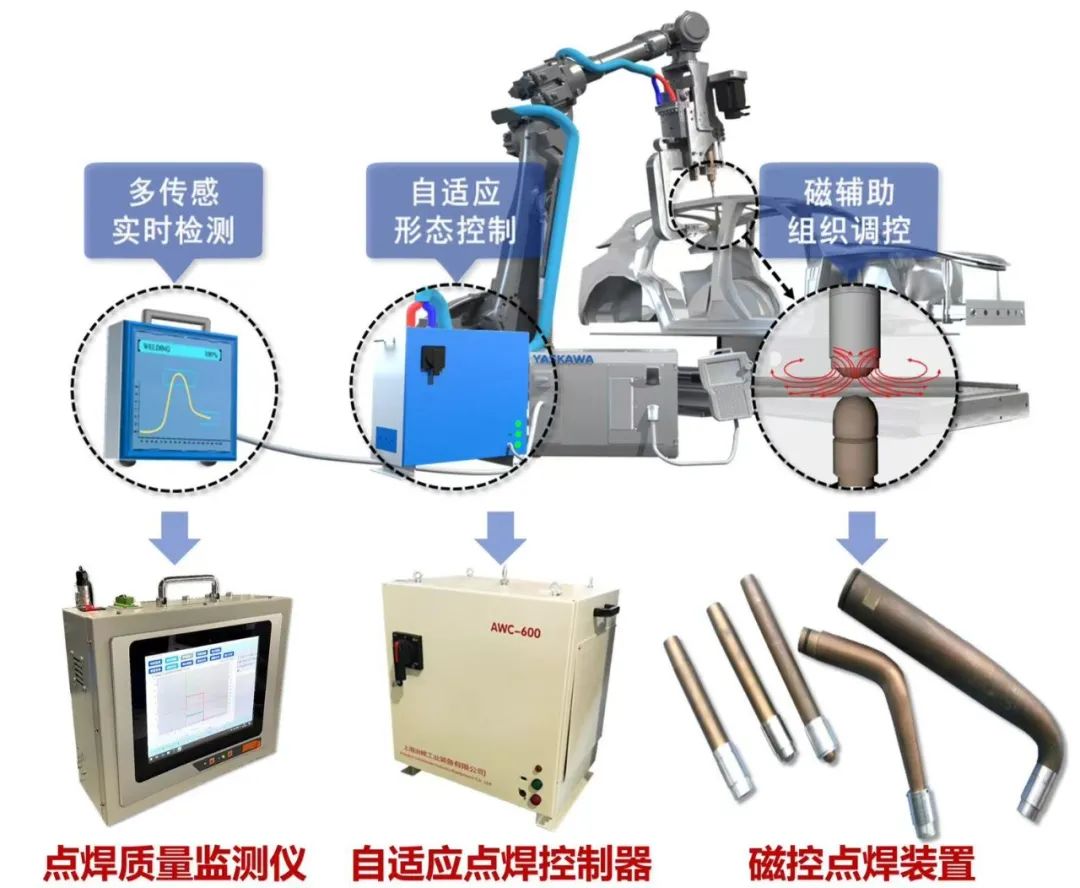

To fill this market gap, Zhirong Equipment has independently developed an intelligent control technology for the quality of resistance spot welds and launched an intelligent resistance spot welding equipment (FusionSmart AWC). It uses a model algorithm combining mechanism and AI for online automatic full inspection of quality + intelligent real-time quality control, achieving millisecond-level real-time tracking and adaptive control with an accuracy rate of over 99%. The intelligent equipment can detect problems in advance, saving man-hours and costs for maintenance or rework, and transforming the traditional manual off-line inspection and adjustment into automatic online prediction and monitoring, which is suitable for scenarios with high-precision and high-reliability requirements. The products have been applied in enterprises in the fields of automobiles, aerospace, and rail transit.

Intelligent resistance spot welding series products

On the supply chain side, Zhirong Equipment has the ability to design, produce, install, and debug the above equipment, and self-produces core process consumables such as rivets, and will complete overall production expansion in the future. "From the basic process, core technology, overall structural design to process consumables and the equipment itself, we are all independently controllable, which effectively ensures the stability and controllability of the overall product," Lei Haiyang said. The independent controllability of the product design in the early stage also largely determines the cost control in the later stage.

In terms of the team, Professor Li Yongbing, the chairman and chief scientist of the company, is a National Outstanding Youth Fund winner and also serves as the director of the Thin Plate Structure Manufacturing Research Institute. The core team has been deeply involved in the field of thin plate welding and connection for more than 20 years, and all core members graduated with a doctorate from Shanghai Jiao Tong University. Zhirong Equipment has a well-established talent echelon and is a leading R & D team in the field of point connection globally. It has experience in the R & D of new processes, technology application, software development, and the development and implementation of intelligent equipment, and can develop new fasteners and equipment in a short time to achieve effective material connection.

Zhirong Equipment has perfect experimental and inspection means, including robot spot welding systems, robot arc welding systems, SPR, FDS, F-SPR, and Clinch, and provides static mechanical performance testing areas, fatigue mechanical performance testing areas, metallographic preparation areas, and metallographic observation areas to support the company's process development and new material technology adaptation needs. The company also actively responds to the trend of AI empowering the manufacturing industry, and uses industrial application models to assist enterprises in optimizing the closed-loop from product design, process parameters in the early stage to quality inspection in the later stage, realizing the full-link connection of welding and connection in specific business scenarios.

In the future, Zhirong Equipment is planning to develop connection technologies for the same and different lightweight materials such as magnesium alloys, carbon fiber composites, and engineering plastics, as well as welding and connection process simulation software, which will be the focus of the company's next development. At the same time, the business will expand to fields such as low-voltage electrical appliances and low-altitude economy. Especially in the low-altitude economy, drones and eVTOL have an urgent demand for efficient connection of lightweight materials.

Investors' views:

Zhongying Venture Capital said, We have always been concerned about new technologies in the field of intelligent manufacturing and found that lightweighting is a definite trend in the automotive, rail transit, and aviation industries. The F-SPR process, which was first developed internationally by Professor Li Yongbing, the founder of Zhirong, solves the problems of riveting cracking, poor airtightness, and slow speed of lightweight materials, especially low-ductility light alloys (such as aluminum and magnesium alloys) in these industries, achieving "penetrating without breaking and welding without leakage", leading technological breakthroughs in the field of point connection. Since investing in Zhirong, the company's business progress and execution ability have exceeded expectations, and it has reached cooperation with industry leaders in each application field. We also look forward to Zhirong expanding more product categories, implementing more scenarios, and empowering Made in China to move onto the international stage with technology.

Image source on the homepage | Provided by the enterprise

Typesetting | Liu Siya

This article is from the WeChat public account "Yingke", author: Wu Ruoyu. Republished by 36Kr with permission.