Breaking through import monopoly and achieving hundred - ton - scale mass production of key semiconductor powder materials, "Xici New Energy" completed nearly ten million yuan in Angel + round financing | Exclusive from 36Kr

Text | Zhang Bingbing

Editor | A Zhi

36Kr learned that Beijing Xici New Energy Technology Co., Ltd. (hereinafter referred to as "Xici New Energy") recently completed an angel + round of financing of nearly ten million yuan. The investment was jointly made by Jinqiao Fund, Shuimu Venture Capital, Shangshi Capital, and the industrial investor shareholding platform Xici Zhongyou. The funds will be mainly used to supplement the working capital of the synthetic quartz sand mass production line.

Founded in 2019, "Xici New Energy" focuses on the preparation technology of key powder materials for platform - level third/fourth - generation semiconductors. It has deployed multiple products such as aluminum nitride, silicon carbide, and synthetic quartz sand, which are widely used in fields such as semiconductor substrates, chip thermal management, and special structural parts. The founder, Ding Xifeng, has obtained a bachelor's degree and a doctorate from Tsinghua University and has been engaged in chemical engineering - related work.

Currently, "Xici New Energy" has built a hundred - ton - level synthetic quartz sand mass production line and pilot lines for silicon carbide and aluminum nitride powders. The products are supplied to leading customers. After the customer consistency verification is completed, it is expected to enter the mass - production stage in the second half of 2025.

I. Pioneering the Organic - Inorganic Polymer Gel Method to Self - Develop High - Purity and Low - Cost Synthetic Quartz Sand

High - end powder materials such as synthetic quartz sand and silicon carbide belong to the upstream of the third/fourth - generation semiconductor industry chain. Among them, synthetic quartz sand is the key raw material for manufacturing quartz crucibles and quartz profiles. As the "container" for single - crystal silicon growth, the quartz crucible determines the quality of silicon wafers; quartz profiles are used in all aspects of chip manufacturing to ensure process accuracy.

For a long time, high - quality synthetic quartz sand for semiconductors has relied on imports, and Japan's Mitsubishi Chemical has a monopoly position globally. Dr. Ding Xifeng, the founder of "Xici New Energy", introduced that Mitsubishi Chemical's production process is the hydrothermal method, which uses organosilicon for hydrolysis under high temperature and high pressure. This method produces products with high purity and strong particle uniformity. However, the problem is that the cost is too high, so the selling price of synthetic quartz sand has always remained high.

In the "Industrial Structure Adjustment Guidance Catalog" of the "14th Five - Year Plan", high - purity quartz raw materials are listed as encouraged products for key breakthroughs. Domestic enterprises have also tried to use various technical routes to achieve domestic substitution of synthetic quartz sand, including the sol - gel method, chemical vapor deposition method, and water glass ion - exchange method. However, since the above technical routes cannot balance quality and cost or are difficult to achieve mass production, the quartz sand used in high - end fields has never achieved domestic substitution.

"We applied the polymer technology in organic polymers to inorganic powder materials across industries and developed the polymer gel method, taking into account factors such as purity, quality, and cost." Ding Xifeng further introduced that the polymer gel method of "Xici New Energy" uses relatively cheap silicon - containing industrial by - products as raw materials, polymerizes them in an aqueous solution, polymerizes them into polymer precursors at normal temperature and pressure, and then obtains high - purity synthetic quartz sand products through high - temperature treatment.

The polymer gel method reduces the cost of raw materials and overall equipment investment on the one hand. On the other hand, during the polymerization process, the polymer units can form low - boiling - point complexes with impurities in the raw materials, which are removed during the high - temperature calcination stage, thus solving the problem of powder purity.

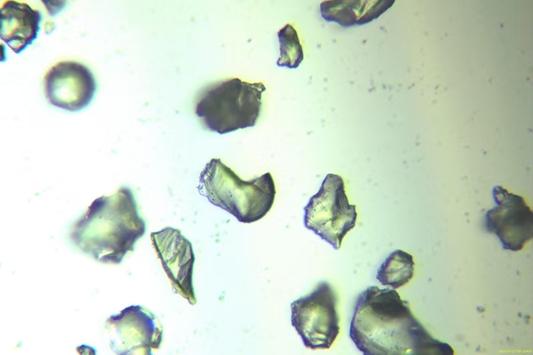

High - purity synthetic quartz sand products of "Xici New Energy"

"Xici New Energy" has currently mass - produced two high - purity synthetic quartz sand products with different purity specifications: the 5N8 - grade product for partially replacing imported natural quartz sand and the 7N - grade product for replacing imported synthetic quartz sand. The particle size distribution of the products can be adjusted between 75μm and 200μm, and the cost is significantly reduced.

During the process of process scaling - up, "Xici New Energy" addressed the problem of uneven quality from small - scale tests, pilot tests to mass production from both scientific and engineering aspects. On the one hand, the team solved the underlying problems based on the understanding of the core mechanisms of processes such as addition polymerization and dehydration condensation. On the other hand, with the team's engineering experience, it solved engineering problems such as heat and mass transfer during the chemical engineering scaling - up process.

II. Synthetic Quartz Sand is on the Verge of Mass Production, Promoting the Mass Production of Silicon - Series Products

Through the platform - level technology of powder synthesis by the polymer gel method, "Xici New Energy" has now deployed two product lines: silicon and aluminum. Among them, the silicon series includes high - purity synthetic quartz sand, semiconductor - grade 4H - silicon carbide powder, and ceramic - grade 3C - silicon carbide powder; the aluminum series is aluminum nitride powder, a thermal conductive material for third/fourth - generation semiconductors, which can be widely used in fields such as semiconductors, optical fiber communications, the photovoltaic industry, and precision optical devices.

"Our powder materials are basic materials in the upstream of the industry chain. In applications in different industries, the requirements for powders are similar. For example, in the silicon carbide industry, whether it is new energy vehicles or UHV power transmission, there are various silicon carbide devices, but the requirements for the silicon carbide material itself are almost the same." Ding Xifeng analyzed. Currently, the overall market situation of the semiconductor industry is on the rise. In the next 3 - 4 years, "Xici New Energy" will focus on expanding customers in the semiconductor industry.

As products aiming for domestic substitution, the key factors that customers consider are stability and cost - effectiveness. "We are quite confident about cost - effectiveness. Now we have just entered the customer's supply chain, and customers definitely need some time to evaluate the stability of our products. Only when the performance of each batch can be kept stable will they start large - scale substitution." Ding Xifeng believes that the polymer gel method combines traditional and mature chemical processes, with relatively good process maturity. At the same time, continuous production is maintained for quality control, which will ensure that the stability of the entire product is verified by the market.

Mass production line of "Xici New Energy"

In this process, "Xici New Energy" is also continuously cooperating with upstream and downstream enterprises in the industry chain to consolidate its competitive advantage. Upstream in the industry chain, it cooperates with leading enterprises to stabilize the raw material supply; downstream in the industry chain, it introduces industrial investment parties during the mass - production stage to expand market applications and bind major customers.

Currently, "Xici New Energy" has sent samples to the leading first - tier suppliers in the industry, received small - batch test orders, and started supplying to some leading customers. Ding Xifeng expects that a large number of stable procurement orders will start after the customer consistency verification is completed, and it will enter the mass - production stage in the second half of 2025. The overall revenue is expected to reach the ten - million - yuan level in 2026, and with the production of silicon carbide and aluminum nitride products in 2027, the revenue will further increase.

In terms of future planning, "Xici New Energy" will expand its market share in the domestic semiconductor industry, bind important customers, and strive to achieve full - load production of the existing production lines next year. On the other hand, it will promote the transition of silicon carbide from the pilot stage to the mass - production line, and strive to build a silicon carbide mass - production line next year and enter the trial - production stage.

36Kr Future

"36Kr Future Industry" continuously focuses on urban development, industrial transformation, and the implementation of innovation and entrepreneurship projects. For media coverage, please contact wangfengzhi@36kr.com by email or scan the QR code to contact the author.

In addition, 36Kr officially launched the "36Kr Corporate Investment Guide Internal Reference" this year. Relying on its deep accumulation in the economic circle industrial clusters, regional key promotion plans, and investment promotion fields, 36Kr provides in - depth, detailed, timely, and exclusive comprehensive information services to government departments, providing them with efficient and accurate industrial project internal references; helping project parties match industrial funds, connect with key contacts, and quickly integrate into the new industrial ecosystem.

This article is from the WeChat official account "36Kr Future Industry". Author: Zhang Bingbing, A Zhi. Published by 36Kr with authorization.