Financing Premiere | Mass production via 3D printing accelerates. Bolli Advanced Materials completes over 200 million yuan in Series B financing.

Author: Hanhai

Editor: Azhi

36Kr learned that recently, Suzhou Boliy New Material Technology Co., Ltd. (hereinafter referred to as "Boliy New Material") completed its Series B financing, raising over 200 million RMB. Led by Luzhou Aviation Development Group and Zhilai Investment, with multiple strategic investors participating, and existing shareholders GSR Ventures, Oasis Capital, and Zhongxin Innovation further increasing their stakes. The funds from this round of financing will be used to accelerate the R & D of 3D printing mass - manufacturing technology, the construction of factories, and the exploration of AI technology applications in the 3D printing industry.

Accelerate Factory Construction and Achieve Mass Production of 3D Printed Shoes

Since its establishment, Boliy New Material has been committed to the R & D of 3D printing materials centered around elastomer materials and the mass - manufacturing of 3D printed products. To solve the problem of slow traditional printing speed, it developed the HALS (Hindered Asynchronous Light Synthesis) 3D printing technology, which boosts the printing speed to 20 - 100 times that of traditional technology, providing a foundation for Boliy New Material to achieve mass - manufacturing of 3D printed products. Currently, the 3D printing terminals developed by Boliy New Material based on this technology are mainly applied in fields such as medical, consumer, sports equipment, education, and cultural and creative industries.

It has been four years since the previous round of financing (July 2021) until this new investment. During this period, Boliy New Material mainly focused on process upgrading, factory construction, and business expansion exploration. Boliy New Material's first factory was built in 2020. As of May this year, factories have been established in Suzhou, Wuhu, Yangzhou and other places. To achieve mass production on a million - level scale, Boliy New Material has built an intelligent cloud factory system. The intelligent cloud factory simplifies, intelligentizes, and enables real - time production management through a central production management system.

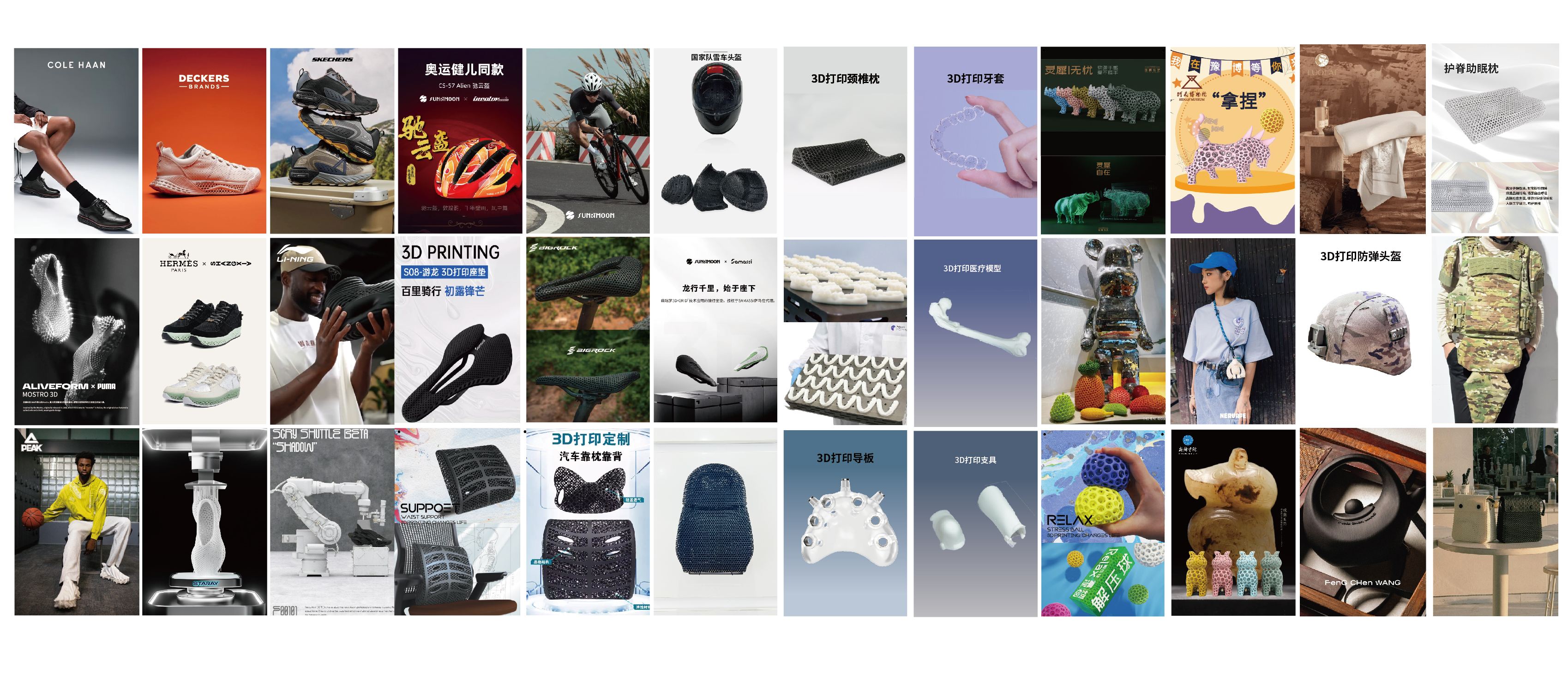

3D Printed Shoes

3D printed shoes are an important part of Boliy New Material's business. Currently, its 3D printed shoe solutions cover modules such as shoe accessories, midsoles, one - piece shoes, trial shoes, and shoe molds. The production of shoes has achieved high - speed growth for four consecutive years. In terms of product categories, it includes sports shoes, leather shoes, slippers, marathon shoes, outdoor stream - crossing shoes, safety shoes, labor - protection shoes, etc. Partner brands include domestic and international sports brands such as Li Ning, Peak, and Skechers. The mass production of 3D printed shoes has been listed by the Ministry of Industry and Information Technology as a typical case of the first batch of 3D printing additive manufacturing application scenarios in China.

Applications of High - Performance Materials in Consumer and Industrial Fields

In the consumer field, Boliy New Material's elastomer materials bring new possibilities for improving product comfort and functionality. Taking its application in footwear products as an example, this material has excellent mechanical properties and resistance to bending fatigue, reliable safety performance, and outstanding ventilation and shock - absorption characteristics. Its special molecular structure can efficiently absorb the impact force when the foot lands, providing good shock - absorption effects and effectively reducing joint damage caused by sports. At the same time, the highly breathable design of the material allows air to circulate freely inside the shoe, expelling the moisture generated by the feet in a timely manner, keeping the feet dry and comfortable at all times, and bringing an unprecedented comfortable experience to consumers during sports.

In addition to footwear, this elastic material is also applied in products such as bicycle seats and shock - proof helmets. In shock - proof helmets, its energy - absorption characteristics can effectively disperse the impact force, protecting head safety; when applied to bicycle seats, it can dynamically disperse pressure according to the human sitting posture, making users less likely to feel tired during long - distance cycling. Compared with traditional materials, the newly developed elastomer bio - based material of Boliy New Material is superior in terms of durability and environmental protection, providing strong support for the upgrade of daily life and sports safety products.

For industrial products, heat dissipation and lightweighting are key factors in improving product performance and competitiveness. In the manufacturing of industrial parts, this elastomer bio - based material can effectively conduct heat. For example, when applied to the shells of some products, its special lattice structure, chemical composition, and microstructure can quickly dissipate the heat generated by electronic components, avoiding problems such as performance degradation and shortened lifespan caused by overheating of the equipment, and significantly improving the stability and reliability of the equipment. In terms of lightweighting, for weight - sensitive fields such as robot manufacturing and aerospace, Boliy New Material's high - performance materials greatly reduce the weight of components while ensuring high strength. Taking the production of humanoid robots as an example, using Boliy's 3D printed multi - layer structured honeycomb composite material (including related technologies of elastomer bio - based materials), this material has multiple characteristics such as high elasticity and performs excellently in shock absorption, lightweighting, and heat dissipation. Data shows that it has a high energy absorption rate and strong deformation recovery ability, which not only improves the mobility of the robot, making its movements more flexible and agile, but also reduces energy consumption and extends the battery life.

Application Scenarios

When it comes to the company's future development plan, Wang Wenbin put forward the concept from AIGC to AIGT (Artificial Intelligence Generated Terminal Products): "By collecting product usage data through the Internet of Things to feed back to the AIGC algorithm, a dynamic closed - loop of 'design - manufacturing - iteration' is formed. On the basis of AIGC significantly improving the R & D and design efficiency, after the 3D printing intelligent cloud factory is connected to the AIGT system, cross - regional production capacity scheduling can be achieved, and overseas customized orders can be completed within 48 hours from 'design - printing - global delivery'."

In addition to continuously increasing production capacity, achieving the transformation from AIGC to AIGT in the 3D printing industry will be Boliy New Material's next goal.

Investors' Views:

Yuan Zhiqiang, Chairman of Luzhou Aviation Development Group:

As a leading non - metallic additive manufacturing enterprise with outstanding R & D capabilities, a stable market scale, and strong demand for expansion, investing in Boliy New Material to build a mass - production base in Luzhou will fill the gap of Luzhou Aviation Development Group in non - metallic additive manufacturing, help build a production capacity agglomeration area for the non - metallic additive manufacturing industry, promote the exploration of application scenarios such as 'additive manufacturing + medical', 'additive manufacturing + consumer goods', and 'additive manufacturing + consumer electronics', and drive the construction of the industrial ecosystem and large - scale development.

Hao Wenju, Partner of Zhilai Investment:

Investing in Boliy New Material is a strong proof of our long - term optimism about the track of the integration of 3D printing and artificial intelligence. From a longer - term perspective, the combination of 3D printing and artificial intelligence will completely reshape the entire manufacturing industry landscape.

In the foreseeable future, with the continuous advancement of technology, 3D printing will gradually break through the current application boundaries. In the high - end manufacturing field, such as the manufacturing of precision electronic equipment, traditional manufacturing processes face dual challenges of precision and efficiency when dealing with the production of small and complex parts. Boliy New Material's 3D printing technology, combined with intelligent control and optimization realized by artificial intelligence, can manufacture electronic parts with more delicate structures and more excellent performance, meeting the demand for the continuous miniaturization and high - performance development of electronic products.

In the medical and health industry, the combination of 3D printing and artificial intelligence also holds great potential. Through in - depth analysis of patients' medical imaging data, artificial intelligence can precisely design personalized implants and medical devices, which can then be quickly manufactured with the help of 3D printing technology. This can not only improve the accuracy and efficiency of medical services but also bring a better treatment experience to patients, promoting the medical industry to move towards personalization and precision.