"Xingkeyuan" Completes Tens of Millions of Yuan in Angel + Round Financing after Achieving Hundred-Kilogram-Level Mass Production of Silicon-Carbon Anode Materials for Solid-State Batteries | Exclusive Report by 36Kr

Text | Zhang Bingbing

Editor | A Zhi

36Kr learned that Hangzhou Xingkeyuan New Material Technology Co., Ltd. (hereinafter referred to as "Xingkeyuan") recently announced the completion of a multi - million - yuan Angel + round of financing. The investor in this round of financing is Yuanhe Origin. Previously, it had received angel - round investments from Sequoia China Seed Fund, Matrix Partners China, Lingge Venture Capital, Tsinghua Alumni Fund, Yundao Capital, and industrial investors, and Yundao Capital served as its long - term exclusive financial advisor. This round of financing will be mainly used for the development of new - generation products and to break through large - scale mass production based on technological iteration.

Founded in January 2022, "Xingkeyuan" focuses on the production and R & D of silicon - carbon anodes for lithium batteries and is also reserving next - generation nano - silicon technology for solid - state batteries. The team members mainly come from universities such as Tsinghua University, Peking University, and the Massachusetts Institute of Technology, and have many years of practical experience in the fields of nanomaterials, anode materials, solid - state batteries, and equipment manufacturing.

"Xingkeyuan" independently designs and develops new - generation CVD nano - silicon manufacturing equipment, silicon - carbon material synthesis equipment, etc. It has developed a number of process technologies such as nano - silicon products with high dispersibility and easy surface modification and high - specific - capacity anode materials, and has sent samples in bulk to leading manufacturers.

Seize the core nano - silicon raw material and self - develop silicon - carbon anode material technology

Under the explosive growth trend of new energy, lithium batteries face performance bottlenecks such as energy density and charging efficiency. In the field of battery material innovation, finding anode materials with higher specific capacity has become one of the current research focuses. The theoretical specific capacity of silicon - based anode materials far exceeds that of traditional graphite materials, and it can significantly improve the charging and discharging efficiency of lithium batteries, making it an ideal new - type anode material.

However, when silicon is fully lithiated, its volume will expand by 100% - 300%. The huge volume change will cause the material to crack or be damaged, thus affecting the battery's lifespan and performance, which has become the biggest problem in the practical application of silicon - based materials.

The silicon - carbon composite material technology is currently the recognized route to solve this problem. However, in actual production, there is no fixed pattern for its process and mass - production equipment, which has become a breakthrough point for innovative enterprises to compete. Leading international companies such as Group 14 mainly use gas - phase silicon - carbon technology, and its core product SCC55™ has won orders from multiple new - energy vehicle and consumer electronics companies.

Unit gram capacity, initial efficiency, cycle life, and rate performance are important dimensions for evaluating the performance of anode materials. Li Xuegeng, the founder of "Xingkeyuan", believes that the essence of gas - phase silicon - carbon technology is the secondary granulation of high - specific - capacity nano - silicon particles, which takes into account both high initial efficiency and ultra - long cycle performance. The underlying logic is the performance balance brought by ultra - fine nano - silicon. Therefore, the core of "Xingkeyuan"'s differentiated technological path lies in nano - silicon technology.

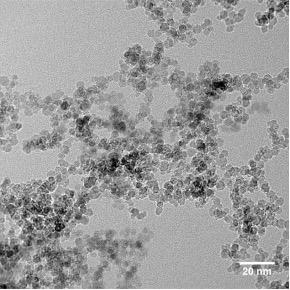

"Our nano - silicon technology has a 20 - year accumulation and can ensure the production of nano - silicon at the nanometer level, which is the team's strongest advantage." According to Li Xuegeng, the founder of Xingkeyuan, the previously developed nano - silicon was mainly used for quantum - dot light - emitting materials in fields such as LEDs and medical display agents. In the field of lithium - battery applications, "Xingkeyuan" can prepare ultra - fine nano - silicon particles smaller than 10 nm and achieve particle - size adjustment between a few nanometers and dozens of nanometers.

Nano - silicon products

Compared with other processes, "Xingkeyuan"'s nano - silicon has a small particle size, a controllable particle - size distribution, no hard agglomeration between particles, and is easier to disperse. It can achieve good dispersion in solutions, having both quantum effects and being not easily broken, thus achieving high specific capacity and long - cycle stability. On this basis, in - situ carbon coating and in - situ doping can reduce the processing difficulty and resistivity of nano - silicon, leaving room for the subsequent development of silicon - carbon anode processes.

"After the ultra - fine and highly dispersed performance is achieved, there are more possibilities for coating, such as carbon coating, ceramic materials, and polymer materials." Li Xuegeng further explained that the team is also increasing investment in the development of pure nano - silicon and composite silicon materials to reduce costs, enabling the products to ultimately have the competitive advantages of low cost, high compaction, high rate, and fast charging.

Stably mass - produce silicon - carbon anode materials and target the application of next - generation solid - state batteries

In the field of new materials, there has never been a shortage of technological breakthroughs in the laboratory. Silicon - carbon anode materials have extremely high requirements for product consistency and stability. To achieve large - scale mass production and commercial application, strong control of production equipment and engineering capabilities is required.

"Xingkeyuan" chose to self - develop production equipment and aimed at large - scale industrialization from the beginning. Li Xuegeng said: "All our technological equipment is designed for ton - level production. We never do production at the level of dozens or hundreds of grams. Because if the engineering problems are not solved, there will be problems with the product later. So we have strong engineering capabilities and a solid foundation, which is different from other companies in the market."

It is reported that the CVD production equipment self - made by "Xingkeyuan" can achieve continuous production. After the equipment is ignited, only by continuously introducing silicon precursors and carbon sources can carbon - coated nano - silicon materials be continuously produced. As long as the process parameters are set exactly the same, the materials can be continuously produced, without the problems of poor batch consistency and stability. In addition, the silicon - carbon composite materials developed by "Xingkeyuan" have better compression resistance than gas - phase silicon - carbon. On the basis of ensuring the current initial efficiency, they can also realize composite functional materials, making the product's conductivity and fast - charging performance more prominent.

Currently, "Xingkeyuan" is focusing on the verification stage of the pilot - scale production, and has achieved stable production and delivery of ultra - fine nano - silicon and nano - silicon powder materials at the hundred - kilogram level, realized large - scale in - situ coating processes, and the preparation technology of various in - situ doped composite materials. At the same time, in response to the differentiated needs of different customers, "Xingkeyuan" has developed universal base materials suitable for both aqueous and oily systems, and the results have been delivered to multiple customers, including leading enterprises in the industry, for quality testing.

According to a relevant research report from CITIC Securities, with the expansion of application scenarios and the increase in the blending ratio, silicon - carbon anode materials are expected to gradually enter the stage of accelerated industrial introduction and increasing demand. It is estimated that the global demand for silicon - carbon anode materials is expected to reach 60,000 - 70,000 tons in 2026.

"The combination of solid - state batteries with high - end demand scenarios such as low - altitude economic drones, electric vehicles, artificial intelligence, and robots has extremely high requirements for battery performance, which in turn has paved the way for a large market and opportunities for us." Li Xuegeng analyzed that after the launch of next - generation solid - state batteries, ultra - high - specific - capacity power batteries have higher requirements for fast charging, which is a prerequisite for occupying a larger market.

Based on this, "Xingkeyuan" will adopt the idea of prioritizing R & D. In response to customer needs, it will invest a large amount of resources in the R & D of new - generation products. It will also cooperate with leading enterprises to launch universal products that can serve multiple solid - state battery manufacturers, and continuously optimize product processes based on usage requirements to obtain customers with stable products. At the same time, in terms of industrial layout, it will look for areas to build kiloton - level production lines to further release production capacity.

Views of the investors:

Le Jinxin, a partner at Yuanhe Origin: China's lithium - battery technology continues to lead the international wave, developing in a safer, more efficient, and greener direction. Yuanhe Origin highly focuses on breakthroughs in advanced materials and processes in this field and delivers core value to the industrial chain. The Xingkeyuan team has a completely independent and innovative technological route and industrialization experience in the R & D and preparation of nano - silicon and composite silicon - carbon materials. Its products are expected to provide stable performance in all - solid - state batteries, enabling downstream customers and even China's lithium - battery industry to maintain a leading position globally. We also look forward to deeply participating in the global layout of China's new - energy industry based on our investment in Xingkeyuan and related projects.

Cao Jishan, the founding partner of Yundao Capital: Yundao Capital highly recognizes the strategic foresight and technological breakthrough capabilities of the Xingkeyuan team in the field of new materials. It has built a full - chain technological barrier from the preparation of nano - silicon raw materials to the mass production of silicon - carbon composite materials. The technical indicators of its ultra - fine silicon particles smaller than 10 nm have reached the international leading level, providing an innovative solution to break through the industrialization bottleneck of silicon - based anodes. The development strategy of universal base materials also shows strong commercial extensibility and will be fully applied in large scenarios such as smart cars, embodied intelligence, and drones in the future. We will continue to leverage our advantages in industrial resource integration to help Xingkeyuan seize the first - mover advantage in the new - energy material revolution and grow into a globally competitive benchmark enterprise.

36Kr Future Industries

"36Kr Future Industries" continuously focuses on urban development, industrial transformation, and the implementation of innovation and entrepreneurship projects. For media coverage, please contact wangfengzhi@36kr.com by email or scan the code to contact the author.

In addition, 36Kr officially launched the "36Kr Corporate Investment Guide Internal Reference" this year. Relying on its deep accumulation in the economic circle's industrial clusters, regional key promotion plans, and investment promotion fields, 36Kr provides in - depth, detailed, timely, and exclusive comprehensive information services to government departments, providing them with efficient and accurate industrial project internal references; it also helps project parties match industrial funds, connect with key contacts, and quickly integrate into new industrial ecosystems.

This article is from the WeChat official account "36Kr Future Industries". Author: Zhang Bingbing, A Zhi. Republished by 36Kr with permission.