From "domestic substitution" to "global competition": The strength of "Made in China with Intelligence" behind the nine new products of Genesis.

"Machine tools" are machines that manufacture other machines and are the cornerstone of the manufacturing industry. However, for a long time, the domestic high - end CNC machine tool market has been mainly occupied by foreign brands. At the CIMT 2025 China International Machine Tool Exhibition, we saw a group of domestic machine tool enterprises that are continuously climbing towards the high - end market and constantly pursuing technological innovation, which are attracting wide attention.

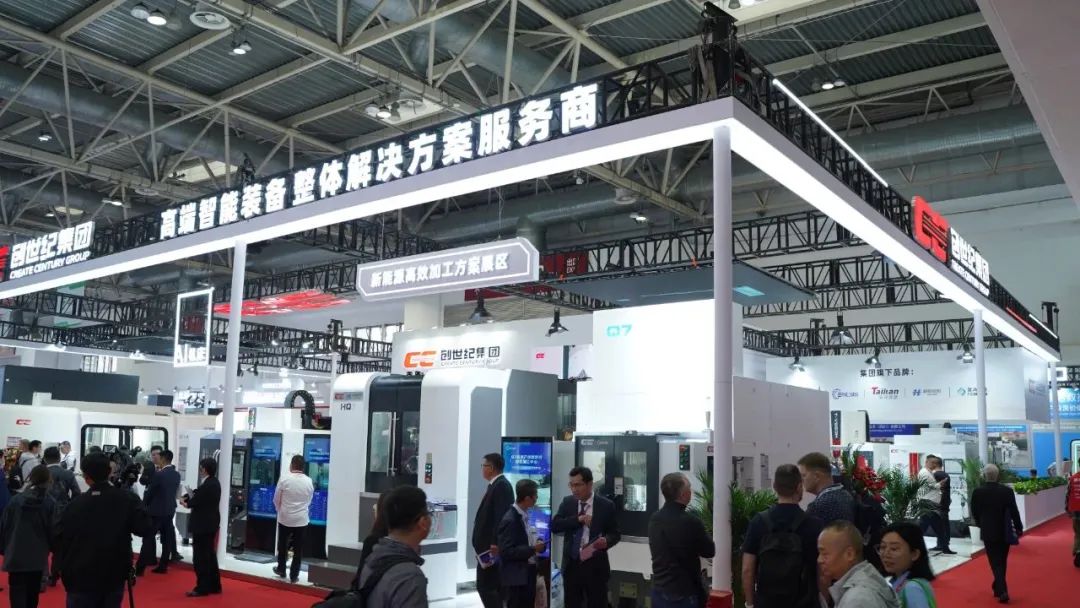

Genesis Group is one of them. At the CIMT 2025 exhibition site, Genesis launched 9 new - generation high - intelligent machine tools and demonstrated a number of innovative achievements, including AI intelligent control systems and multi - axis linkage technology.

What the multiple innovative achievements represent is not just a more intelligent and efficient machine tool solution. The product evolution of "machine tools" has a more important meaning behind it, which is to let the world feel the charm of "Made in China with Intelligence", promote "Made in China with Intelligence" from "domestic substitution" to "global competition", and achieve industrial upgrading.

Launch 9 New Products, Demonstrating R & D Strength

Genesis has already achieved "dancing with the world".

At the CIMT 2025 exhibition site, various types of machine tools exhibited by Genesis, such as AI intelligent machine tools, five - axis vertical machining centers, five - axis drilling and tapping machines, and multi - head engraving machines, were surrounded and inquired by many on - site audiences.

The 9 series of machine tool products launched this time cover models such as high - speed drilling and tapping centers, vertical machining centers, horizontal machining centers, five - axis linkage machining centers, seven - axis machining centers, and multi - head machining centers, which are widely used in strategic industries such as new energy, 3C electronics, automobile parts, humanoid robots, and low - altitude economy.

According to Zhang Han, a technical expert from the Central Research Institute of Genesis Group, the core technical highlights of the 9 new products include an intelligent control system based on AI algorithms, which can realize self - optimization of processing parameters and self - diagnosis of faults. Through the industrial Internet, it can achieve equipment interconnection and remote collaboration, dynamically compensate for processing errors, and achieve "autonomous perception, autonomous decision - making, autonomous control, and autonomous learning", improving the processing accuracy to the micron level;

Many of the new products also have multi - axis linkage technology, which breaks through the bottleneck of complex surface processing and meets the high - difficulty requirements of fields such as aerospace and precision molds. Moreover, by optimizing the power system and thermal management design, it achieves a balance between high performance and low power consumption, reducing energy consumption by 20% - 30%.

Among the AI series of machine tools, the high - speed drilling and milling machining centers represented by the T - 500B and the vertical machining centers represented by the T - V856S are already industry best - selling products with cumulative sales of over 100,000 and over 40,000 units respectively. The T - 500B is also the champion product of the 7th National Manufacturing Single - item.

Through in - depth integration with AI, it not only reduces the warm - up time and improves production efficiency but also can effectively predict the interference of workpieces, tools, and fixtures, increase the service life of tools, and ensure the healthy operation status of the machine tool in real - time. Simply put, compared with traditional machine tool equipment, intelligent machine tools become smarter, more stable in performance, and more reliable in quality through AI empowerment.

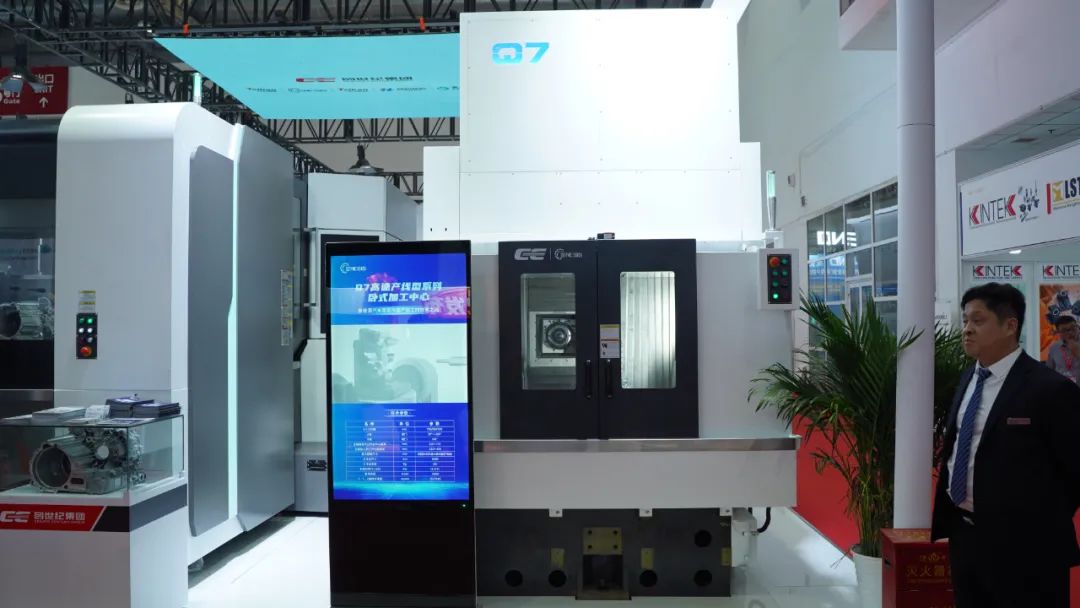

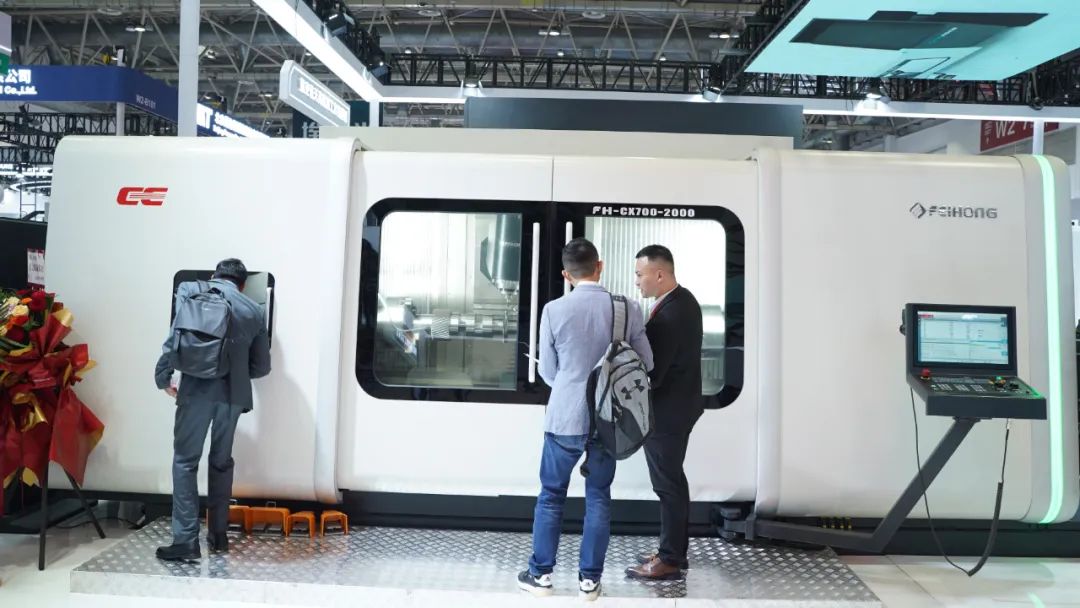

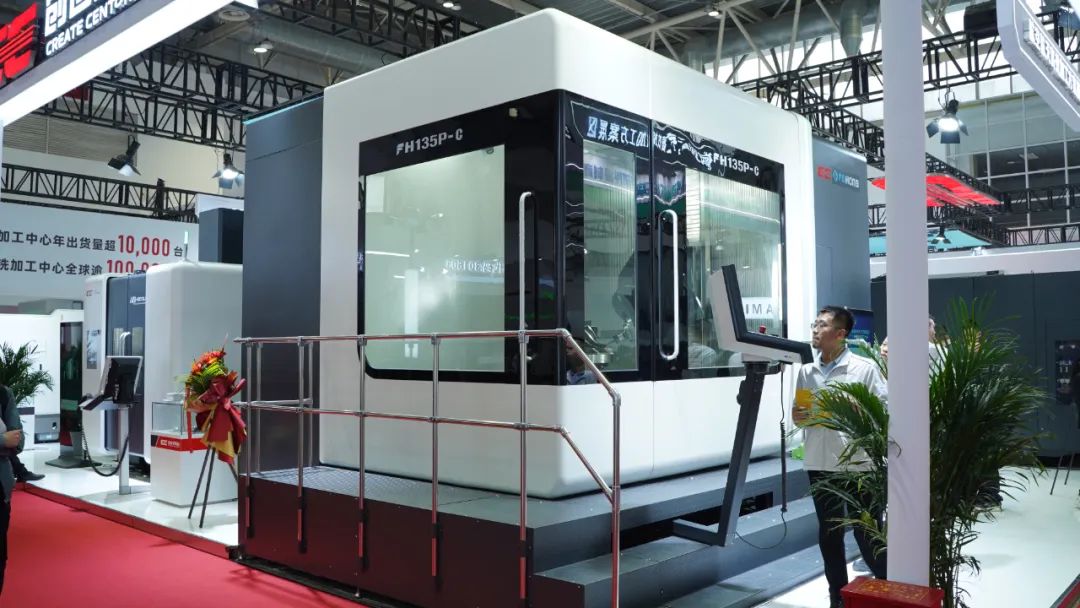

Meanwhile, Genesis also launched a number of five - axis series products, including the high - speed horizontal five - axis machining center Q7, the vertical five - axis machining center V - 800U, the five - axis linkage milling and turning compound machining center FH - 135P - C, and the seven - axis linkage turning and milling compound machining center CX700 - 2000. Among them, the seven - axis linkage design can realize the compounding of various processing functions such as turning, milling, drilling, and boring, achieve the processing of large and complex parts, and complete multiple processing tasks through one clamping, significantly improving processing efficiency and part accuracy and reducing clamping errors.

Five - axis and seven - axis are also typical features of high - end machine tool equipment, which are widely used in fields such as aerospace, shipbuilding, energy equipment, and the automobile industry, and can meet the efficient processing needs of complex parts. The successful independent R & D of relevant products represents that domestic machine tools are constantly catching up with the international top level. The improvement of the international competitiveness of domestic machine tools will also provide strong support for China's industrial and high - end manufacturing industries.

Years of R & D, Achieving Leadership

"Machine tools" are an industry strongly supported by national policies. The "Made in China 2025" plan proposes that by 2025, the domestic market share of high - end CNC machine tools and basic manufacturing equipment will exceed 80%.

According to the statistics of the Straits Research report, the global machine tool market reached approximately $120.19 billion in 2024 and is expected to increase to $129.2 billion in 2025. As the world's largest machine tool producer and consumer, the market scale of China's CNC machine tools was approximately 200 billion yuan in 2023. Among them, the proportion of high - end machine tools represented by five - axis linkage CNC machine tools in high - end equipment manufacturing was only about 10% - 15%, and the overall market was between 20 billion and 30 billion yuan, with foreign - funded brands accounting for the majority.

According to the data of the Zhongshang Industry Research Institute, Chinese CNC machine tool enterprises are mainly positioned in the mid - low - end market. Although the penetration rate of high - end products is increasing, it is still at a relatively low level. In 2024, the localization rates of mid - and low - end CNC machine tools were 65% and 82% respectively, while that of high - end CNC machine tools was 6%.

In fact, in the global machine tool market, Japan, Germany, the United States, and China occupy a relatively large market share. China's machine tool industry has formed a relatively complete industrial system. However, due to its late start, compared with the world's advanced level, it is still "big but not strong". High - end products and core components mainly rely on imports, which makes China still face the problem of being "stuck in the neck" in the field of high - end CNC machine tools.

In other words, in the competition pattern of China's high - end CNC machine tool industry, foreign - funded enterprises occupy a dominant position, while domestic enterprises play the role of catch - up. However, as a group of domestic enterprises represented by Genesis accelerate their transformation and upgrading and make breakthroughs in domestic high - end CNC machine tools, this gap is constantly narrowing.

In recent years, Genesis' high - end products have achieved rapid development: In 2021, Genesis launched innovative products such as the S series and SE series general - purpose drilling and milling machining centers; in 2022, it launched the V - 200U and V - 400U vertical five - axis machining centers, the DH - 63 double - workbench horizontal machining center, and the HQ5 high - efficiency horizontal machining center; in 2023, it launched the high - efficiency vertical machining center T - V850, the V - 500U, V - 650U, and V - 800U vertical five - axis machining centers, and the DMT400 gantry vertical machining center...

Now, Genesis' high - end intelligent equipment business has formed multiple series, including drilling and milling machining centers, vertical machining centers, horizontal machining centers, gantry machining centers, engraving and milling machining centers, profile machining centers, CNC lathes, swiss - type lathes, and five - axis machining centers.

In just a few years, the coverage of multiple high - end products would not have been possible without Genesis' R & D investment in high - end products. According to the financial report, in 2024, the company had 370 R & D personnel, and the annual R & D investment reached 124 million yuan.

Currently, through continuous technological R & D breakthroughs, Genesis' products have accumulated multiple advantages in terms of comprehensive product performance, technological level, cost - effectiveness, and local services in the 3C industry, with strong brand influence and market competitiveness, leading the industry in market share;

In the general product fields such as humanoid robot joints, automobile parts, automation equipment, mechanical processing, mold processing, parts processing, rail transit, medical devices, and the new energy vehicle field, the relevant products deployed by Genesis have also been widely recognized by customers.

High - speed Growth in Performance, Leading with Dual - wheel Drive

With long - term accumulation and hard work, the continuous investment in product R & D has also enabled Genesis to find a path for high - quality enterprise development in a market where the low - end machine tool market is relatively saturated and high - end machine tools rely on imports.

Data shows that in 2024, Genesis achieved a total revenue of 4.605 billion yuan, a year - on - year increase of 30.49%; the net profit attributable to the parent company was 237 million yuan, a year - on - year increase of 22%; the annual sales revenue of the advantageous product, the 3C drilling and milling machining center, reached 1.926 billion yuan, a year - on - year increase of 197.43%; the R & D and sales of high - end machine tools such as five - axis CNC machine tools and large - scale horizontal machining centers made substantial progress, with annual sales of 200 million yuan, a year - on - year increase of 39.09%...

As time entered 2025, Genesis continued this development momentum. Its just - released first - quarter report for 2025 shows that during the reporting period, it achieved a revenue of 1.048 billion yuan, a year - on - year increase of 22.37%; the net profit attributable to the parent company was nearly 100 million yuan, a year - on - year increase of 66.51%; the net profit attributable to the parent company after deducting non - recurring gains and losses was 94 million yuan, a year - on - year increase of 145.43%.

The performance of each business line is remarkable. The quarterly sales revenue of the advantageous product, the 3C drilling and milling machining center, reached 410 million yuan, a year - on - year increase of 26.60%; the sales of high - end CNC machine tools increased significantly, and the proportion continued to rise, with sales revenue reaching 46 million yuan, a year - on - year increase of 21.62%; the revenue of other general products (including vertical machining centers, engraving and milling machining centers, gantry machining centers, profile machines, CNC lathes, swiss - type lathes, etc.) was approximately 600 million yuan.

The continuous competitive technological R & D and innovation ability has become Genesis' core competitive advantage. Years of R & D investment have enabled Genesis to be in a leading position in the industry in terms of product matrix construction and core technology autonomy. Genesis pointed out that in the R & D investment layout, it will focus on increasing the R & D resource tilt towards new products and core functional components, while focusing on forward - looking technology exploration, basic theoretical research, and applied technology transformation. In just the first quarter of 2025, its R & D investment exceeded 30 million yuan, a year - on - year increase of 43.17%.

Specifically, first, focus on tackling key problems in the field of high - end CNC machine tools to meet the precision processing needs of industries such as 5G communication, semiconductors, and aerospace for high - end equipment; second, customize and develop adaptive solutions according to customers' personalized needs; third, expand the general - purpose product sequence to achieve wide coverage in the fields of precision processing and intelligent manufacturing; fourth, rely on digital simulation technology and the industrial Internet platform to implement intelligent upgrading and iteration of existing products, and promote the products to extend vertically in the direction of high precision and high reliability.

It is worth mentioning that with the improvement of the product line and product strength, Genesis has also found a second growth curve overseas, and its products are moving from "domestic substitution" to "global competition".

In fact, in recent years, with the improvement of the performance of domestic CNC machine tools and the gradual improvement of the industrial chain, the localization speed of CNC machine tools has been accelerating. More and more domestic machine tool enterprises have begun