"Yuantian Biology" Completes Nearly 100 Million Yuan Pre-A+ Round of Financing after Signing a Kiloton-level Order for Bio-enzymatic Regenerated PTA | Exclusive Report by 36Kr

Text | Zhang Bingbing

Editor | A Zhi

36Kr learned that Yuantian Biotechnology (Tianjin) Co., Ltd. (hereinafter referred to as "Yuantian Biotechnology") recently announced the completion of a nearly 100 million yuan pre-A+ round of financing. The investors include Beiyang Haitang Fund, Shangshi Capital, Daotong Investment, Liaonon, Ren'ai Group, etc. The funds from this round of financing will be used for the construction of a kiloton-scale production line, product technology improvement, and market expansion.

Founded in October 2022 and located in the Tianjin Economic-Technological Development Area, "Yuantian Biotechnology" relies on the full-industry-chain biomanufacturing platform and ton-scale pilot incubation base of Tianjin University to develop the enzymatic regeneration technology for waste PET, achieving the enzymatic production of recycled rPTA and the industrialization of Rb-PET.

"Yuantian Biotechnology" has completed product verification with multiple international brands and domestic listed companies. Its customers cover industries such as textile and apparel, home textiles, food and beverage packaging, automotive, aerospace, etc. Currently, it has started product sales and signed kiloton-scale orders.

Biological enzymatic rPTA achieves hundred-ton-scale mass production

As one of the most common plastic varieties globally, PET has a wide range of applications. Its recycling can significantly reduce plastic pollution in the ocean and soil, while reducing the dependence on non-renewable resources such as petroleum, and decreasing production energy consumption and carbon emissions. It is crucial for environmental protection and resource conservation.

Currently, the relatively mature PET recycling methods are mainly physical and chemical methods. The physical recycling technology is mature, but it is mainly suitable for high-value raw materials such as PET bottle flakes. Its processing capacity for low-value mixed materials such as fibers is obviously insufficient, the raw materials are limited, and the performance declines after recycling. The chemical recycling process has shortcomings, with a large amount of organic solvents used, a long reaction process, high temperature and pressure, and high energy consumption costs.

As an emerging technology in the field of PET recycling, the biological method shows promising technological potential. Dr. You Shengping, the founder of "Yuantian Biotechnology", introduced that this technology uses hydrolase to achieve the degradation and recycling of PET. It has three major advantages: in terms of raw materials, it has stronger adaptability, can process various PET-containing materials, and achieve full-category recycling; in terms of degradation products, it can generate rPTA and rMEG (recycled ethylene glycol) through in-depth degradation by biocatalysis; in terms of the final product, the Rb-PET product has a high grade and can be applied in a wider range of end products such as fiber grade, food grade, and film grade.

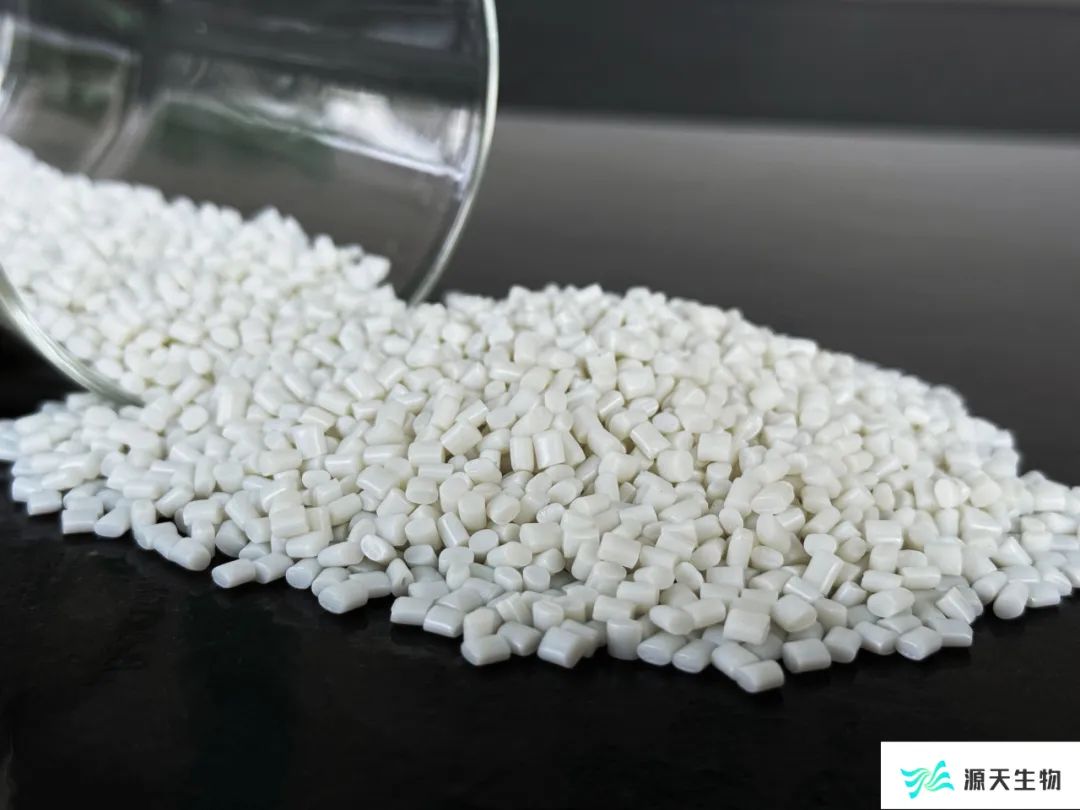

Yuantian Biotechnology's Rb-PET products

"The core advantage of biodegradation lies in the nature of the technology - under normal temperature and pressure conditions, the entire production process uses a full-water system, so it has comprehensive competitiveness in terms of safety. For example, in terms of production safety, employee operation safety, and product application safety, we have significant advantages." You Shengping introduced that the core challenge lies in how to promote this innovative technology from the laboratory to ten-thousand-ton-scale mass production.

The first challenge is the bottleneck problem of enzymes. Natural enzymes have low activity, unstable structures, and are sensitive to reaction conditions. They need to operate under relatively mild conditions and have a long reaction time. In response, based on previous research, "Yuantian Biotechnology" has successfully developed high-performance PET enzyme mutants: on the one hand, it can achieve single-enzyme hydrolysis, saving the cost of enzyme preparations and simplifying the PET enzymatic hydrolysis steps; on the other hand, it uses AI creation technology to achieve the restructuring of the tertiary structure of enzymes and create new enzymes, increasing the enzyme activity by 1920 times and improving the enzyme catalytic efficiency.

The second challenge is how to achieve process scaling up. The world's first 300-ton rPTA production line of "Yuantian Biotechnology" has been in operation for more than half a year, and a 5000-ton production line is under construction. The self-developed systematic process package has become an important barrier. You Shengping introduced: "Different from the situation of small-category products with low cost sensitivity and extensive process management, bulk materials need to compress the cost per ton to the extreme. Even a one-yuan reduction in cost can significantly promote the overall profitability, which requires the process package to be refined to the extreme."

Cost is a frequently mentioned keyword from technology to process, and it is also the third challenge for the large-scale application of biodegradation. The level of cost will affect the choice of market application. In terms of cost reduction, "Yuantian Biotechnology" on the one hand reduces the unit cost through the scale effect with a continuous, automated, and intelligent large-scale production line, and on the other hand works on the industrial chain and technology iteration, promoting standardized cooperation with upstream waste collection enterprises and iteratively improving the catalytic efficiency of enzymes.

"We need to ultimately transform this innovative technology into large-scale production capacity that can penetrate into various scenarios of life, reaching a production scale of millions or even tens of millions of tons." You Shengping summarized.

High-quality recycled materials are recognized by downstream international brands

According to data from Beroe Consulting, in 2024, the global recycled PET market size was 1.051 billion US dollars, and it is expected to reach 1.3817 billion US dollars by 2029. At present, none of the existing PET recycling technology routes can fully meet the market demand.

From the perspective of market opportunities, the European and American markets have promoted the rapid development of green materials through policies and consumer demand. The EU's Carbon Border Adjustment Mechanism imposes additional tariffs on high-carbon products, directly stimulating the demand for low-carbon materials. Leading brands at home and abroad are actively embracing better recycled materials based on the ESG concept.

Jiang Gangwen, the co-founder of "Yuantian Biotechnology", introduced that the core demands of customers include performance comparable to virgin materials, cost competitiveness, and certification endorsements for environmental protection and safety, which are also the competitive advantages of "Yuantian Biotechnology". "Our customers are all top brands at home and abroad, and they welcome us very much. Because the quality of our products can reach the level of petroleum-based virgin materials, there is no problem with the application at the client end, and they can be used immediately after testing."

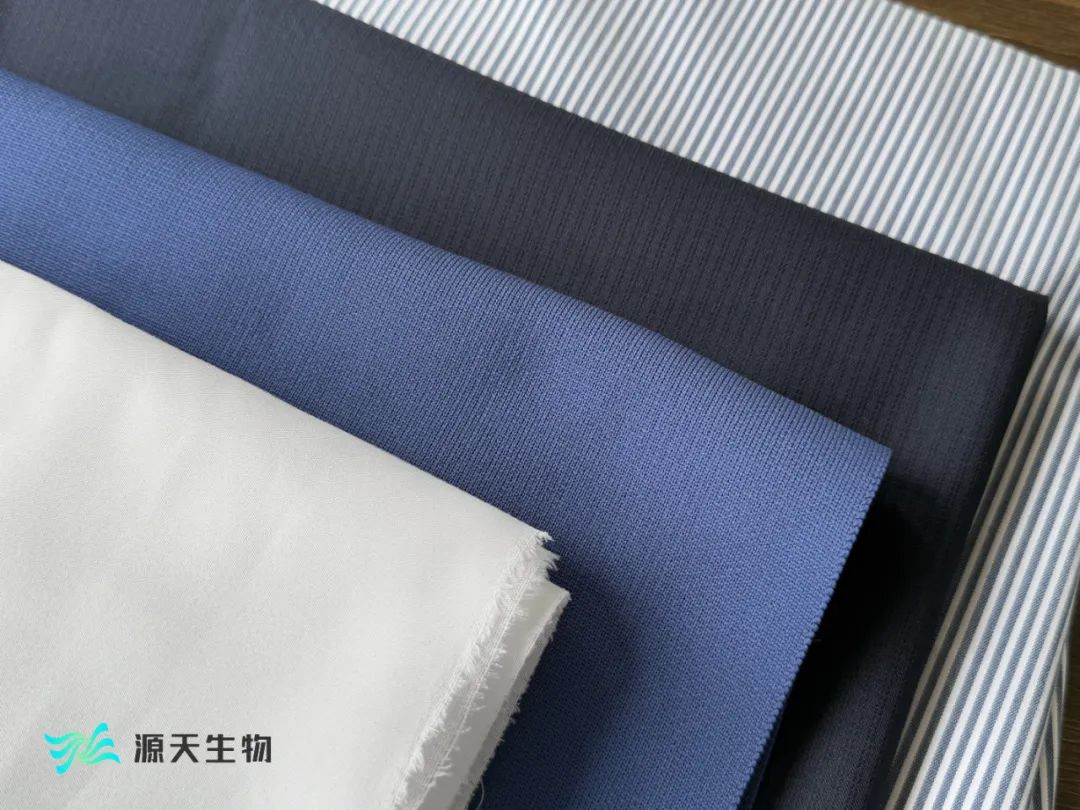

Yuantian Biotechnology's recycled material products

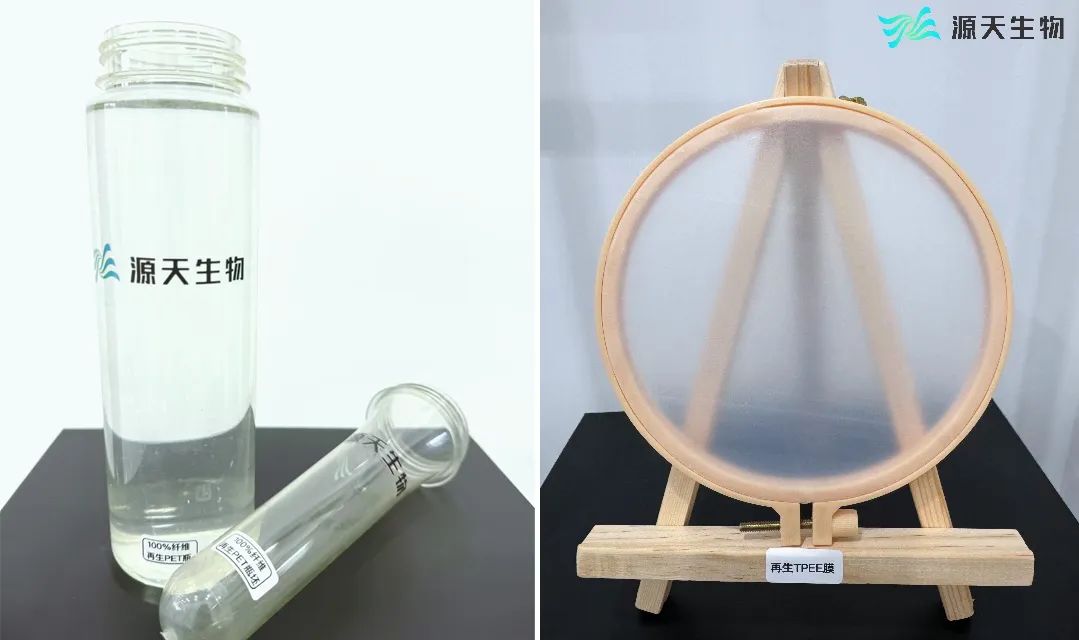

In addition to product cooperation, "Yuantian Biotechnology" is also carrying out closed-loop recycling cooperation with partners. The customers provide raw materials such as waste fibers, and "Yuantian Biotechnology" uses the biological enzymatic hydrolysis technology to decompose them into rPTA and rMEG monomers, and then re-polymerizes them into Rb-PET chips, realizing a complete Textile to Textile cycle. In May 2024, "Yuantian Biotechnology" successfully produced the world's first enzymatically recycled T-shirts/sneakers/PET bottle flakes/PET films, which is of great significance for promoting the recycling of waste fibers.

Yuantian Biotechnology's enzymatically recycled sneakers and clothing

Yuantian Biotechnology's enzymatically recycled PET bottles and PET films

However, it is undeniable that the biodegradation technology route is still in its early stage. The leading French company Carbios is also scaling up its industrialization. The PET biological recycling plant jointly built with Indorama Ventures is under construction. After completion, it will have the capacity to process 50,000 tons of post-consumer PET waste per year, equivalent to 2 billion bottles or 300 million T-shirts.

At the same time, different from the mature markets in Europe and the United States, the relevant policies for PET recycling in China are mainly encouraging, lacking mandatory measures. The growth of market demand requires more product technology to drive it.

This is an opportunity for overtaking on a curve and also a challenge for innovative enterprises. You Shengping admitted that facing the future production scale target of millions of tons, "Yuantian Biotechnology" is still in the pilot test stage. The next core task is to build a 5000-ton production line and at the same time secure more orders from leading customers to strive for hundreds of millions of yuan in revenue.

36Kr Future Industries

"36Kr Future Industries" continuously focuses on urban development, industrial transformation, and the implementation of innovation and entrepreneurship projects. For media coverage, you can contact wangfengzhi@36kr.com by email or scan the code to contact the author.

In addition, this year 36Kr officially launched the "36Kr Enterprise Investment Guide Internal Reference". Relying on its deep accumulation in the economic circle industrial cluster, regional key promotion plans, and investment promotion fields, 36Kr provides in-depth, detailed, timely, and exclusive comprehensive information services to provide government departments with efficient and accurate industrial project internal references; it helps project parties match industrial funds, connect with key contacts, and quickly integrate into the new industrial ecosystem.

This article is from the WeChat official account "36Kr Future Industries". Author: Zhang Bingbing, A Zhi. Republished by 36Kr with permission.