"Jinke Machine Tools" has received a 50 million RMB Series A financing from the Industrial Mother Machine Industry Investment Fund to accelerate the localization of high-end compound five-axis machine tools. | 36Kr Exclusive

Author | Lin Qingqing

Editor | Peng Xiaoqiu

36Kr has learned that recently, the compound five-axis machine tool manufacturer "JinKe Machine Tool" has completed its Series A financing, with an amount of 50 million yuan. The investor in this round is the Industrial Mother Machine Industry Investment Fund, and MuChen Capital serves as the financial advisor for this round and in the long term. The Industrial Mother Machine Industry Investment Fund was established in 2022, with a fund management scale of 15 billion yuan. It is a national industrial fund dedicated to supporting the development of the entire industrial chain of industrial mother machines.

"JinKe Machine Tool" was founded in 2005, with its headquarters located in Jiangmen City, Guangdong Province. It focuses on intelligent manufacturing of machine tools and customized industry solutions. The high-end five-axis machine tool products it researches, develops, and manufactures are widely used in multiple industries such as civil aerospace, automobiles, new energy, medical treatment, jewelry, and molds.

The global manufacturing industry is accelerating its transformation towards intelligence and automation. With the continuous improvement of processing accuracy and efficiency requirements in high-end manufacturing industries such as aerospace and automobiles, the market demand for five-axis machine tools, as a high-end equipment capable of achieving complex processing tasks, continues to grow.

According to statistics from the Straits Research report, the global machine tool market will reach approximately 120.19 billion US dollars in 2024, and it is expected to increase to 129.2 billion US dollars by 2025. As the world's largest producer and consumer of machine tools, the market size of China's CNC machine tools in 2023 is about 200 billion yuan. Among them, the number of high-end machine tools represented by five-axis CNC machine tools in the high-end equipment manufacturing accounts for only about 10 - 15%, with the overall market at 20 - 30 billion yuan, and most of them are foreign brands.

Currently, the domestic machine tool industry still faces the problem of insufficient stability, especially in the popularization of multi-industry applications. Although the gap between domestic machine tools and international brands in performance and functionality is gradually narrowing, there is still room for improvement in stability and the richness of application cases. The high-end machine tool market has extremely high requirements for stability and compounding. Most domestic enterprises are concentrated in the mid-to-low-end market, and the high-end market still relies on imports.

The founder of "JinKe Machine Tool", Kuang Jinfu, once served as a technical instructor in the school-run factory in the early years. "At that time, the domestic manufacturing industry relied on imports for high-end equipment, with high equipment costs and difficult maintenance. We saw the gap between domestic and imported equipment, as well as the potential of the high-end equipment market. Although the domestic machine tool industry has occupied the mainstream in traditional fields such as manual milling machines, foreign equipment has entered the numerical control and automation stage. This gap provides a broad space for the development of domestic machine tools."

Based on this, "JinKe Machine Tool" mainly targeted the high-end market at the beginning of its establishment. Through independent research and development of core components and in-depth secondary development of the numerical control system, it is committed to solving the stability problem of high-end machine tools. Its main product line covers multiple high-end CNC machine tool series, including compound five-axis machining centers, five-axis machining centers, horizontal five-axis machining centers, precision mold machining centers, vertical machining centers, CNC double-head boring machines, and engraving machine tools, etc.

Among them, it is understood that the five-axis machining center series, such as the JK80 five-axis milling and turning compound machining center, is in a leading position in the industry and is widely used in industries such as aerospace, automobiles, new energy, medical treatment, and jewelry. Horizontal five-axis machining centers such as JK80 - 5AXIS and JKG1600 - 5AXIS have passed the selection of famous and high-quality high-tech products in Guangdong Province in 2024. Zhou Shufen, the co-founder of "JinKe Machine Tool", further introduced, "The company is one of the few domestic enterprises that focus on compound machine tools. By integrating multiple processes into one device, it can reduce customer equipment investment and production costs."

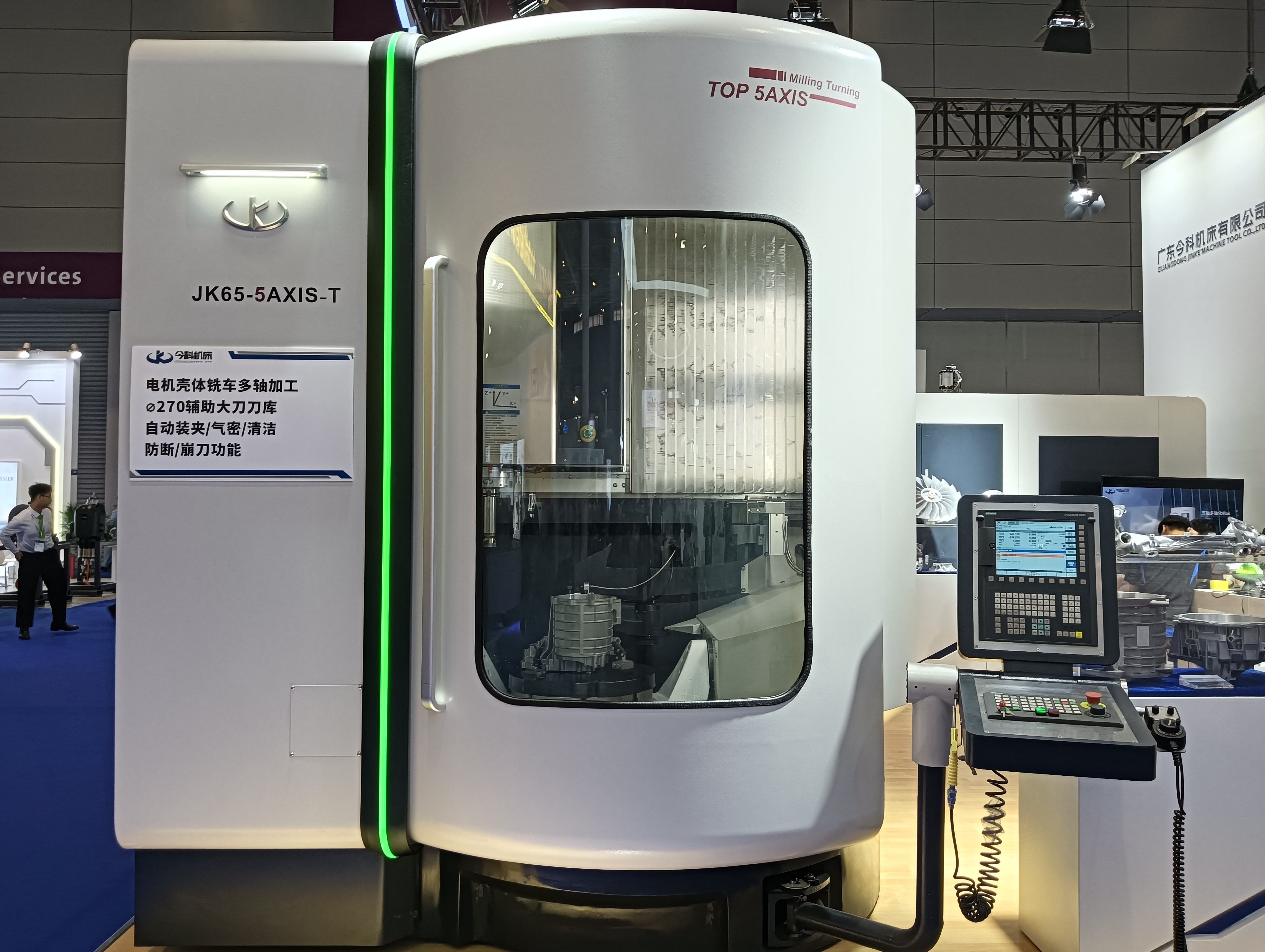

Compound Five-Axis CNC Machine Tool JK65

Among them, the uniBLOCK series and the low center of gravity series are the characteristic products of "JinKe Machine Tool". The former highlights the integral casting bed and the high-rigidity cradle structure, while the latter achieves high-precision and high-rigidity processing through the low center of gravity design and the short overhang Y-axis structure.

From the perspective of the core technical route, the machine tool products of "JinKe Machine Tool" mainly focus on multi-axis, compounding, intelligence, and unmanned operation. Zhou Shufen told 36Kr, "The company has independently developed core components such as precision compound spindles, high-rigidity five-axis turntables, and built-in turntable fixtures, and has carried out secondary development of the CNC system to achieve a highly integrated multi-axis compound function."

It is worth mentioning that, ""JinKe Machine Tool" has achieved the complete interchangeability and high-quality and efficient mass production of machine tool components through self-developed precision working mother machines and ultra-precision guideway grinders."

Currently, the main customers of "JinKe Machine Tool" cover industries such as precision molds, automobiles, new energy vehicles, and medical devices. In the future, the company will focus on the aerospace and military industry.

In addition, "JinKe Machine Tool" plans to focus on the development of intelligent machine tools in the next few years to create an intelligent manufacturing ecosystem. Zhou Shufen believes that, "The domestic machine tool industry is currently in the stage of development from multi-axis to compounding and intelligence. Although the mid-to-low-end market is relatively mature, the high-end machine tool market is still in a critical period of stability improvement and popularization of multi-industry applications. Although the gap between domestic enterprises and international brands in the performance and functionality of high-end machine tools is gradually narrowing, there is still room for improvement in stability and the richness of application cases."

In terms of the team, the founder of "JinKe Machine Tool", Kuang Jinfu, has more than twenty years of industry experience in machine tool technology research and development and enterprise management. The company is equipped with a nearly 30-person R & D team, externally hired technical experts, and possesses a number of core patent technologies.