36Kr Exclusive: A professor from Southern University of Science and Technology starts a business and secures tens of millions of yuan in financing to develop recycled titanium alloy powder.

Author | Zhang Ziyi

Editor | Peng Xiaoqiu

Hardcore Ke learned that Sirui Additive Manufacturing (Shenzhen) Technology Co., Ltd. (hereinafter referred to as "Sirui Additive Manufacturing") announced the completion of a tens of millions of yuan seed round financing. This round of financing is led by "Xiaofanzhuo Ventures" and followed by "Jiayou Fund". Xinpai Capital serves as the exclusive financial advisor for this round of financing.

The funds from this round of financing will be used to promote Sirui Additive Manufacturing to rapidly expand its mass production capacity, increase R & D investment, optimize product performance, reduce costs, and enhance market influence.

Sirui Additive Manufacturing is a technology enterprise that researches, develops, and produces low-cost, high-performance, and environmentally friendly recycled titanium alloy powder and related special metal powders. It was founded and operated by Professor Yan Ming from Southern University of Science and Technology. The metal powder products produced by the company are mainly used in the additive manufacturing fields such as 3D printing and MIM. The company's strategic positioning focuses on the platform-based recycled powder manufacturing and special powder fine-tuning technology. It has now launched a variety of special metal and alloy powder products such as TC4, TA1-4, TA15, Al alloy, Ag alloy, NdFeB, Ta, etc., which are widely used in downstream application scenarios such as 3C electronics, decorative consumer goods, medical, new energy, automobiles, marine engineering, aerospace, etc.

Provided by the enterprise

In the field of additive manufacturing (AM), titanium alloy, as a metal material with high strength, low density, and excellent corrosion resistance, has a wide application field due to its unique properties. With the rapid development of 3D printing technology, the additive manufacturing of titanium alloy can provide more new solutions for the manufacturing of complex components.

Since 2023, the demand for titanium alloy has experienced an explosive growth, mainly concentrated in MIM additive manufacturing and 3D printing enterprises. Data shows that the sales amount of titanium alloy in domestic 3D printing materials ranks first, accounting for 20.2%, and the cost of raw material titanium alloy powder accounts for about 30% of the total cost of 3D printing.

On the one hand, the prices of 3D printing titanium alloy materials have dropped significantly, gradually approaching the requirements of civilian use, and have been used in 3C consumer electronic products such as Apple Watches and Honor mobile phones. On the other hand, with the market growth, a large amount of coarse powder and titanium scrap waste is generated, providing a large amount of raw material supply for recycled powder enterprises.

36Kr has learned that the main manufacturing method of 3D printing titanium alloy powder is the gas atomization powder manufacturing technology. Due to the preparation principle and cost performance and other reasons, this technology is difficult to infinitely reduce the proportion of by-products (coarse powder) (usually as high as more than 40%). A large amount of low-value coarse powder has problems such as difficult recycling and low recycling value, increasing the cost of using powder and 3D printing, and also affecting the profit of the powder manufacturing industry.

The product services provided by Sirui Additive Manufacturing include low-cost recycled titanium powder and high-performance precision-processed titanium powder. The company's technical team has realized the effective recycling and turning "waste" into treasure of titanium/titanium alloy particle waste and titanium scrap through the independently developed metal cold shaping powder manufacturing technology. This technology shapes through physical action without the need for heating, and can convert the recycled material into a near-spherical powder with good fluidity, high purity, low hollow powder rate, and high performance.

In addition, Sirui Additive Manufacturing has a unique technology for post-finishing processing of powder materials. Through means such as pre-deformation and pre-alloying, according to the customer's requirements for the special properties of the molded powder, the powder's own properties such as sphericity, tap density, particle size, and the properties of the molded product such as strength, structure, and composition can be adjusted. Existing products such as ultra-high-strength titanium alloy have a yield strength that is 50% higher than that of the same grade forged parts. This technology helps to promote the application of titanium alloy and other high-performance metal 3D printing in special fields.

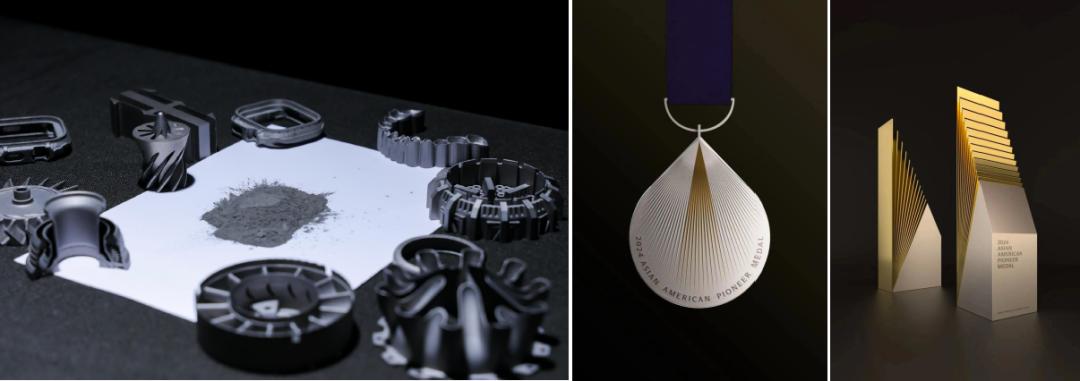

Products made using Sirui Additive Manufacturing powder

Professor Yan Ming said, "It is our long-term pursuit to truly industrialize the technology that the university team has painstakingly researched for many years and promote the application of titanium alloy products."

Dr. Wang Dawei, CEO of Sirui Additive Manufacturing, believes that "Sirui Additive Manufacturing will be committed to exploring the economic value of advanced technologies and expanding the innovative application scenarios of advanced materials such as titanium alloy."

Investor Views:

Xiaofanzhuo Ventures said: The Sirui Additive Manufacturing team has rich scientific research experience and technical accumulation, and has formed its own unique and distinctive technical route in the field of 3D printing titanium alloy and pan-metal materials, which is in line with the current and future social responsibility and the concept of green, low-carbon, and environmental protection, and has successfully realized the mass production and application of this technology in the 3D printing field. We continue to be optimistic about the application of the team's technology and products in downstream related fields, and look forward to Sirui Additive Manufacturing bringing more vitality and opportunities to downstream applications and contributing to the development of 3D printing and new metal materials in China.

Jiayou Fund said: We firmly believe in the future market space of titanium alloy and 3D printing industry. Coupled with the unique cold shaping physical recycling technology of the Sirui Additive Manufacturing team, it is in line with the national development direction of ESG and circular economy. The team with Professor Yan Ming and Dr. Dawei as the core is highly complementary, has accumulated rich scientific research experience and industry resources, and the technology and products have obtained the certification of many industry leading customers. We look forward to Sirui Additive Manufacturing bringing new vitality to the circular economy and 3D printing fields in the future.