The maximum temperature difference is 60 degrees. How to ideally solve the problem of using vehicles in low temperatures in winter?

Written by Angel Li

Edited by Qin Li

When driving a new energy vehicle in winter, what is the function that consumes the most power? The first response of many car owners is the air conditioning.

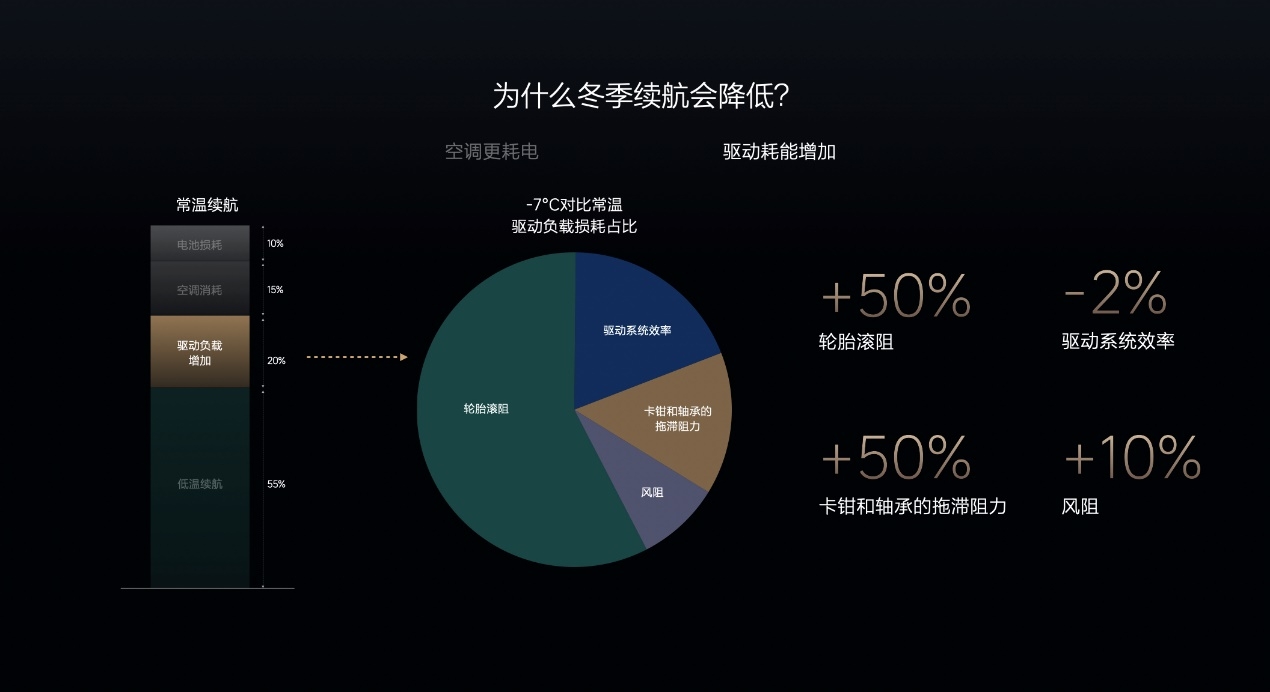

Recently, at the Ideal Auto Winter Vehicle Technology Day, Tang Huayin, the person in charge of the vehicle's electric products of Ideal Auto, introduced that the air conditioning consumption accounts for 15%, and the battery loss accounts for 10%. These are important reasons for the generally "shrinking" range of new energy vehicles in winter.

In addition to the air conditioning, which is a major power consumer, Tang Huayin also said that in a low-temperature environment, the physical properties of materials such as tires change, which will also bring a great driving resistance, resulting in increased energy consumption. For example, at minus 7°C, the tire rolling resistance will increase by 50% compared to the normal temperature state, and the vehicle wind resistance will increase by 10%.

Source: Official

In response to the various pain points of using vehicles in winter, Ideal Auto has made a series of optimization plans on the pure electric model MEGA and the extended-range model Ideal L6.

For example, the slow heating of the vehicle cabin and the uneven temperature distribution are the pain points for many users when using vehicles in winter. Tang Huayin said that in the severe winter in the north, for new energy vehicles to reach a comfortable temperature, the maximum temperature difference that needs to be crossed is 60 degrees.

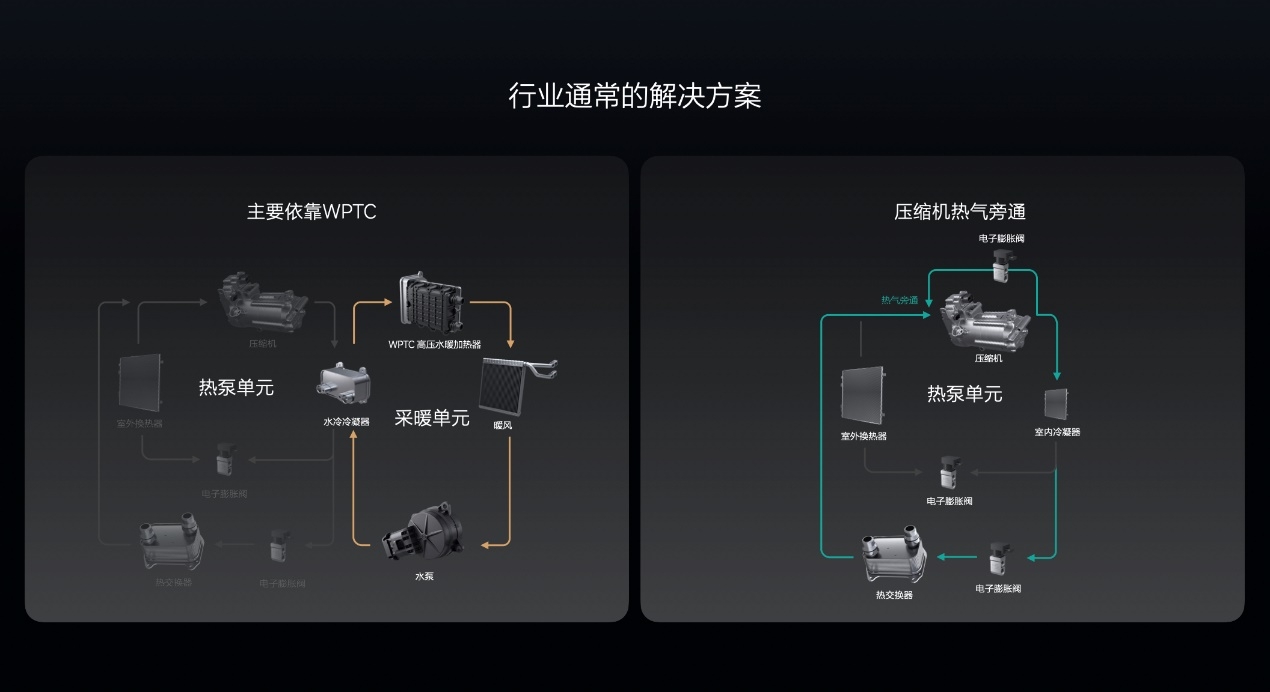

For this reason, Ideal has put a lot of effort into the thermal management system responsible for heating. According to Ideal Auto, at present, most electric vehicles in the industry have two conventional solutions for winter heating. The most widely used is PTC (heater, used to generate heat sources for battery or occupant compartment heating) to directly heat water or air for heating, which is simple and fast. However, to meet the heating needs in colder areas in the north (such as minus 20 degrees), the volume, weight, and energy consumption will increase significantly; In addition, some car companies use the self-heating of the electric compressor for heating, but this heating method has a slow heating speed in the initial stage, a high compressor speed, and a large noise.

Source: Official

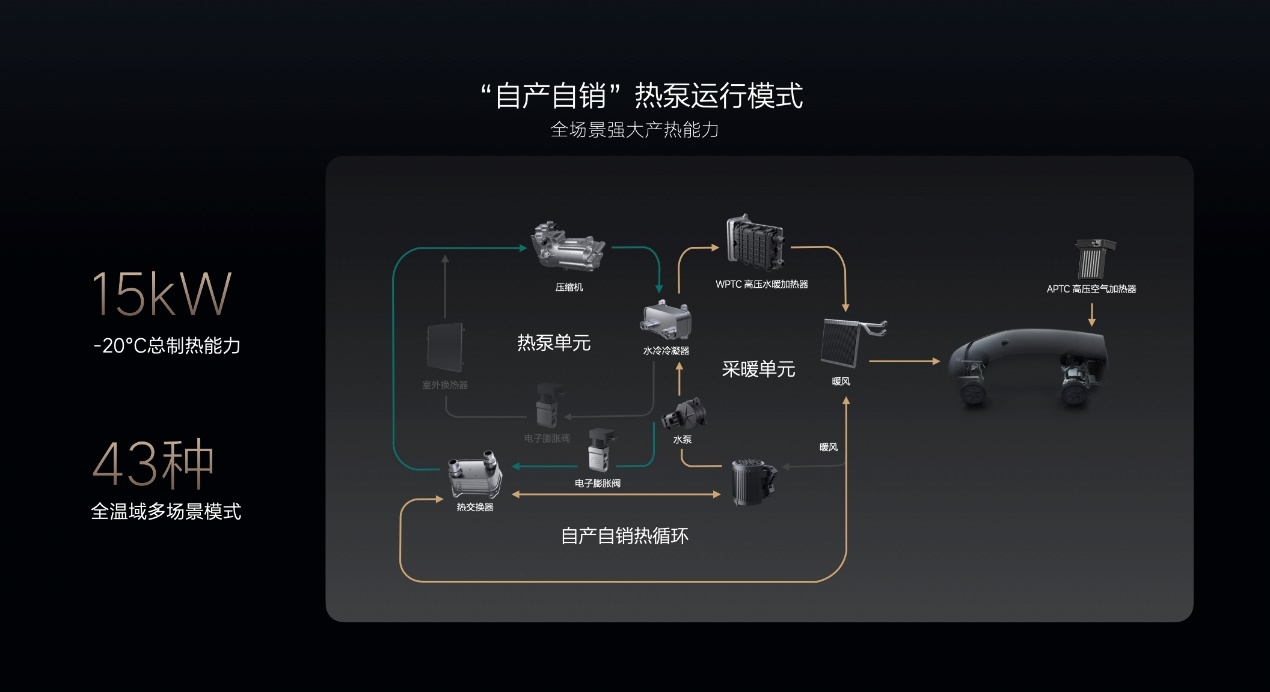

In order to solve the drawbacks of these two conventional solutions, the Ideal MEGA adopts a self-developed multi-source heat pump system, and 43 modes can deal with energy allocation in multiple scenarios. For example, for the problem of poor heating effect of the air conditioning at low temperatures, it can be quickly heated by the compressor's "self-production and self-sale": using the coolant with a still relatively high temperature after the air conditioning heating to quickly heat the refrigerant, activate the heat pump unit, and enable the electric compressor to generate additional heating capacity. The comparison of the heating capacity of this solution with the industry's conventional practices: faster heating speed and greater peak heating capacity.

Source: Official

After solving the problem of air conditioning heating, Ideal Auto has also proposed a series of "increasing income and reducing expenditure" solutions for the vehicle's battery power: reducing air conditioning consumption on the premise of ensuring the comfort of the cockpit, and increasing the source corresponds to the improvement of the battery's low-temperature discharge capacity.

At the "reducing expenditure" level, Ideal has made self-developed innovations in the architecture of the vehicle thermal management system. For example, when commuting in the morning in winter, in the urban driving conditions, Ideal's thermal management architecture can directly use the electric drive to heat the cabin instead of using the battery for heating, which is about 12% more energy-efficient than the traditional battery heating scheme.

This is inseparable from Ideal's integrated design of thermal management components. According to Ideal, the thermal management integrated module of the Ideal MEGA integrates 16 main functional components such as pumps, valves, and heat exchangers, greatly reducing the number of components, reducing the pipeline length by 4.7 meters, and reducing the pipeline heat loss by 8%. On the extended-range model, the Ideal L6 is also equipped with the industry's super integrated module extended-range heat pump system, which solves the problem of space arrangement.

While reducing expenditure, Ideal also aims at the "increasing income" of the battery discharge capacity in a low-temperature environment.

Taking lithium iron phosphate batteries as an example, Li Xiang, the CEO of Ideal Auto, once publicly stated that using lithium iron phosphate batteries in extended-range hybrids and plug-in hybrids is a disaster, mainly because the voltage measurement of this battery is unstable, which will disrupt the control strategy, etc.

At the Winter Vehicle Technology Day, Ideal technicians also introduced that when many lithium iron phosphate battery users use vehicles in winter, the dashboard clearly shows that there is still power, but suddenly there are situations such as loss of speed or even "breakdown". The root cause of this problem is that the lithium iron phosphate battery power is not accurately estimated.

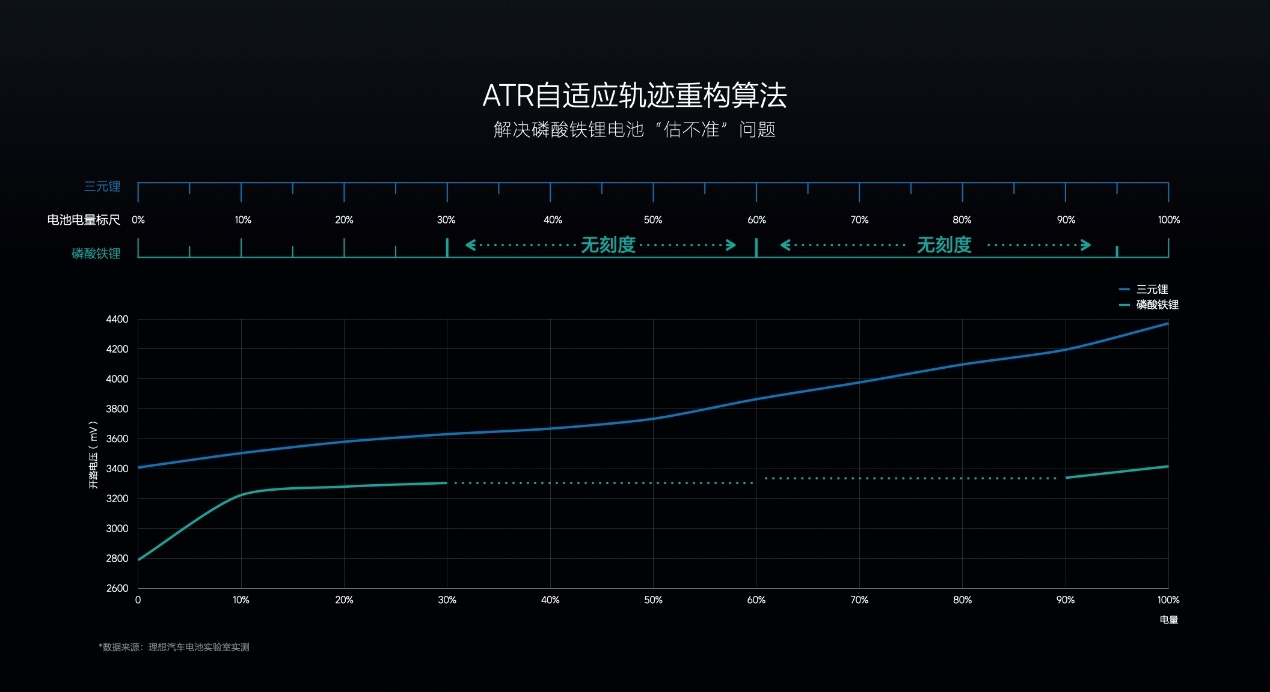

"Inaccurate calculation and weak in low temperature" are the pain points of lithium iron phosphate batteries. According to Ideal technicians, the main reason for the inaccurate estimation of lithium iron phosphate battery power is the few battery calibration opportunities. In contrast, the power of ternary lithium batteries is relatively easy to observe, because its open-circuit voltage and remaining power usually have a one-to-one correspondence, and the power can be accurately estimated by measuring the voltage.

Source: Official

However, lithium iron phosphate batteries are completely different. The same open-circuit voltage may correspond to multiple power values, making it difficult to calibrate the power. Many car companies will recommend that users fully charge the battery regularly for power calibration. However, users of extended-range or plug-in hybrid models are not used to fully charging the battery, making the lithium iron phosphate battery power calibration even more difficult.

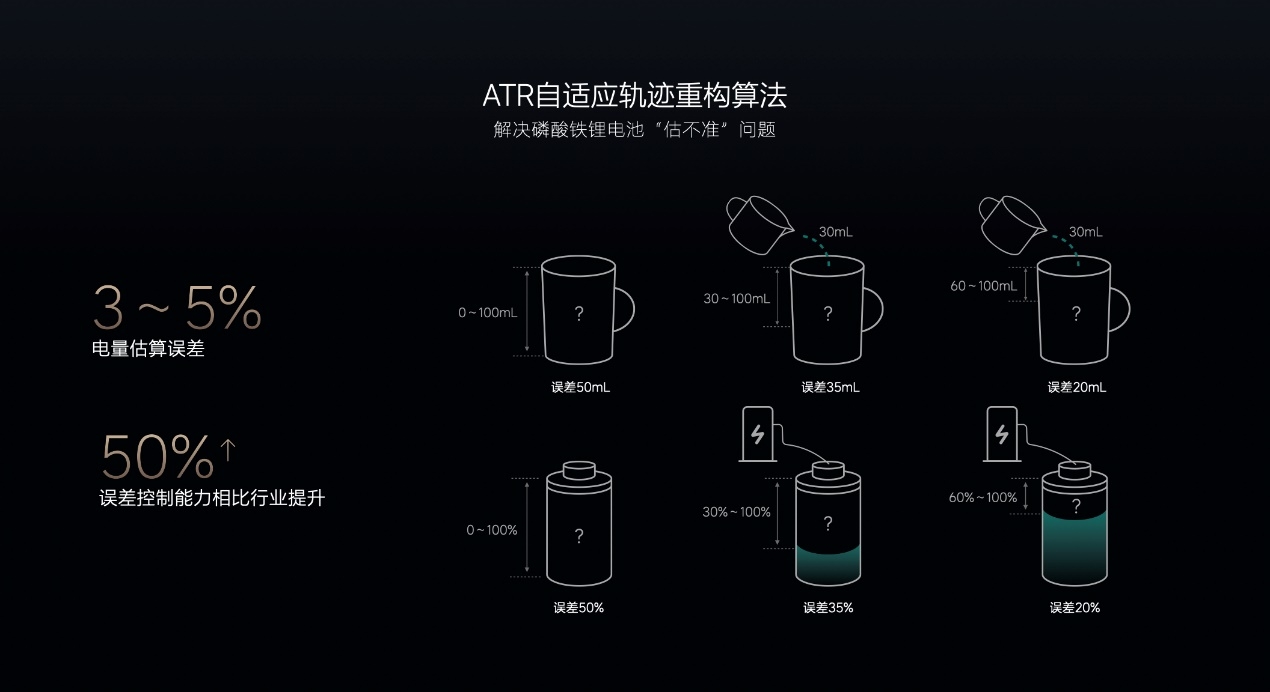

And accurately estimating the power is the prerequisite for using lithium iron phosphate batteries well. For this reason, Ideal said that it has developed the ATR Adaptive Trajectory Reconstruction Algorithm and is the first to apply it on the Ideal L6 model equipped with lithium iron phosphate.

According to Ideal, this algorithm can automatically calibrate the power according to the charging and discharging change trajectory during the owner's daily vehicle use. Even if the user does not fully charge for a long time, the power estimation error can be kept within 3% to 5%, which is more than 50% higher than the industry's conventional level.

Source: Official

In response to the "weak in low temperature" problem, according to Ideal, in the low-temperature winter, the battery discharge capacity is weakened, and the range extender of the vehicle will start in advance when the remaining power is relatively high. This requires further improving the low-temperature discharge capacity of the battery.

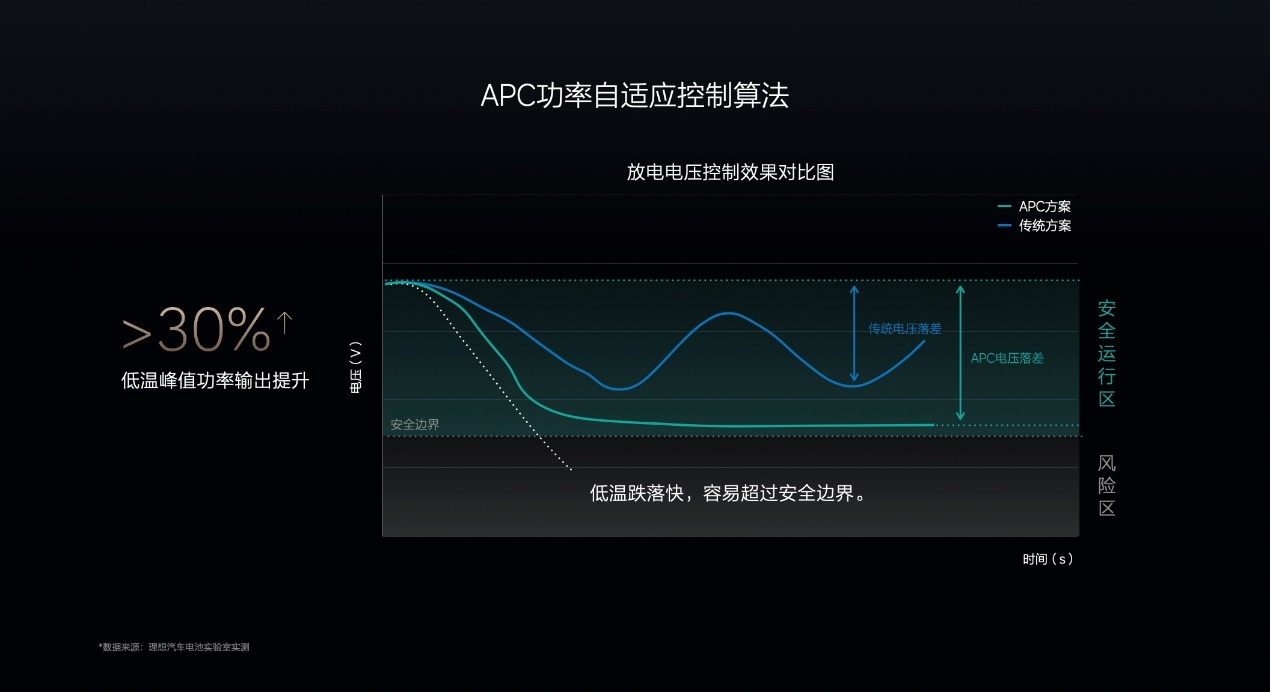

Ideal personnel said that the principle of battery discharge and output power is similar to the discharge of water from a dam. The greater the voltage "water level" drop during discharge, the greater the output power. However, once the voltage is lower than the safety boundary, it will affect the battery life. And the low temperature will cause greater voltage fluctuations than the normal temperature environment, so the industry usually uses a more conservative power control algorithm to limit the voltage drop during battery discharge at low temperatures.

In response to this problem, Ideal has launched the APC Power Control Algorithm. Through a high-precision battery voltage prediction model, it can perform millisecond-level predictions of the battery in future working conditions, and can release the power to the maximum extent within the safety boundary. This enables the battery peak power of the Ideal L6 in a low-temperature environment to increase by more than 30%, and the discharge power before the range extender starts to increase by more than 12%.

Source: Official

On the pure electric model MEGA, Ideal has also jointly developed 5C battery cells with CATL to reduce the internal resistance level of the battery cells, not only achieving the low heat generation requirement during supercharging, but also improving the available power at low temperatures.

For example, Ideal has disassembled the battery cells into three levels and a total of 17 internal resistance components, and optimized them one by one. Finally, the low-temperature impedance of the MEGA 5C battery cells has been reduced by 30%, and the power capacity has been correspondingly increased by more than 30%. At the same time, using CATL's Kirin architecture also enables the Ideal MEGA to have a battery thermal management system with a large heat exchange area, and the entire heat exchange area is 5 times larger than the original bottom cooling solution.

In addition, Ideal has also designed a set of intelligent pre-cooling and preheating algorithms, which can keep the MEGA at the optimal charging temperature. For example, after setting the navigation route to the supercharging station, the vehicle can adjust the battery preheating start time and preheating water temperature adaptively according to the real-time battery status. When the vehicle arrives at the station, the battery temperature can be in the optimal range.