Valued at over $1 billion, this robot joint company ranks first in global sales | Hidden unicorn

Author | Huang Nan

Editor | Yuan Silai

In the spring of 2025, the opportunities to enter the robotics industry are rapidly slipping away.

In the past, investors who focused on the consumer sector have been scouring robotics projects comprehensively. Projects that were yet to be finalized were completed overnight, and hesitant people suddenly became decisive and bold.

The growth rate of humanoid robot bodies is gradually hitting a bottleneck, and many people are turning their attention to the large and complex industrial chain behind robots.

However, the window of opportunity has narrowed to a mere crack. In the past two years, while the wave of humanoid robots was still brewing beneath the surface, some companies in the upstream industrial chain had already grown into low - key but valuable targets.

Zero Difference Cloud Control is such a case. It was founded in 2016 and specializes in the production and manufacturing of high - reliability and high - precision core components for robots, including robot joints and encoders. In 2018, based on its self - developed high - precision encoders, Zero Difference Cloud Control pioneered the design of standard integrated joint modules and entered mass production. During this period, it completed multiple rounds of tens of millions of yuan in financing, with companies such as Bilin Capital, Amber Capital, and Songbai Investment participating successively. Currently, the company's valuation far exceeds 1 billion yuan.

Long before the emergence of humanoid robots, there had been a large demand for joints in various fields, such as surgical robots and service robots in the medical scenario, and automobile manufacturing and 3C electronics in the industrial scenario.

"When we made the joint size smaller, the humanoid robot market wasn't popular yet," Jia Xiqing, the founder of Zero Difference Cloud Control, told Hard Krypton. "Not only the humanoid robot market, but other industries also have increasingly segmented demands. For example, laparoscopic surgical robots, which have a strong and urgent need, can achieve faster and more precise surgical methods, reduce the wound area, and shorten the healing time. At the same time, they make remote surgery possible, allowing people in remote areas to receive surgical operations from professional doctors."

Zero Difference Cloud Control also represents the current situation of most companies in the industrial chain. They won't leave their fate in the hands of the uncertain humanoid robot industry but instead earn revenue in more mature fields first.

Currently, Zero Difference Cloud Control's products have been applied in various fields, including industrial robots, collaborative robots, surgical robots, logistics robots, bionic robots, and humanoid robots. There are more than 2,000 downstream customers, including leading technology manufacturers, robot companies, and automobile manufacturers at home and abroad. The cumulative shipment of robot joints is nearly 50,000 sets, and its sales volume ranks first in the industry.

According to Jia Xiqing, in the current revenue structure of Zero Difference Cloud Control, the joints used in industrial, logistics, and medical scenarios contribute the largest proportion of revenue, accounting for nearly 50% in total. In addition, the sales of humanoid robots account for nearly 15% and have been growing rapidly in the past two years.

It can be seen that the greatest advantage of Zero Difference Cloud Control is its stability. They rely on existing customers to maintain a lower limit, while humanoid robots provide an unknown upper limit and open up greater room for imagination. According to data from Gongyan Research Network and GGII, the demand for robot joint modules in China reached 2.2417 million sets in 2024 and is expected to increase to 4.8201 million sets by 2030, with the market scale potentially exceeding 68.927 billion yuan.

"Currently, the demand from humanoid industry customers for integrated joints mainly focuses on smaller volume, lighter weight, higher load capacity, and reliability. At the same time, when entering the consumer interaction scenario, how to further reduce costs has become the key. In the short term, this is also the main direction of our product iteration. We believe that as robots are more widely used in daily life, there is still huge development potential in the joint market to be further explored," said Jia Xiqing.

Harmonic and planetary reducer joints will coexist in the long term

Whether it's industrial robots and collaborative robots participating in quality inspection and cargo handling on the production line, service robots providing guidance and navigation in shopping malls, or humanoid robots performing on the Spring Festival Gala stage, the precise operation of joints is indispensable behind every smooth and accurate movement.

The performance of joints directly determines the precision, speed, and flexibility of a robot's movement. In different types of robots, due to differences in the operating environment and task requirements, the joint configuration and key components used also vary. Among them, the common shape design mostly adopts a modular approach, integrating motors, reducers, drivers, encoders, and other sensors into a power output unit.

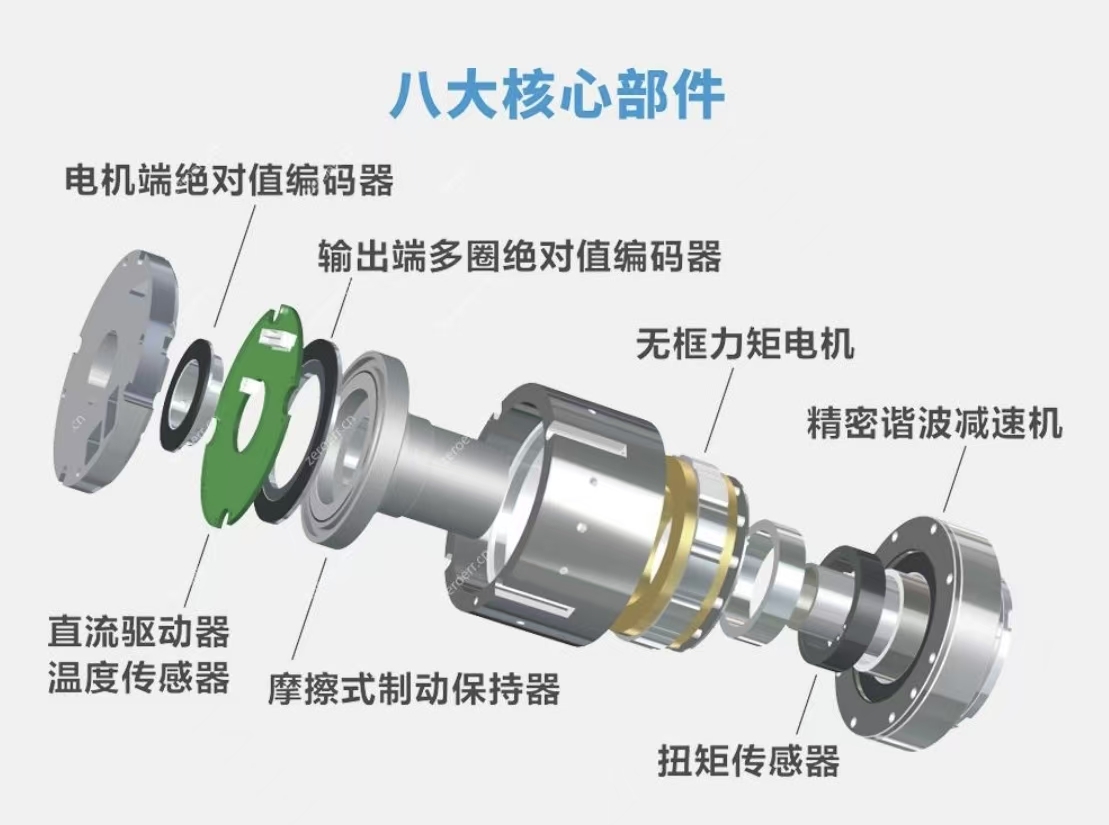

Looking at the composition of Zero Difference Cloud Control's joint components, it is generally composed of an absolute encoder at the motor end, a multi - turn absolute encoder at the output end, a frameless torque motor, a harmonic reducer, a brake retainer, a servo driver, and a torque sensor.

Core components of Zero Difference Cloud Control's motor (Source/Enterprise)

Among these, the encoder is equivalent to a precise "angle feedback system" of a machine. It can monitor the position of the robot joint in real - time and feed this information back to the control system.

In Zero Difference Cloud Control's eRob series of joint module products, absolute encoders with a repeat positioning accuracy of ±7 arc - seconds and an absolute positioning accuracy of ±15 arc - seconds are built into both the motor end and the output end of the reducer, forming a full - closed - loop position control to avoid the impact of backlash, wear, and manufacturing errors of the reducer on the positioning accuracy of the robot joint. This is currently the harmonic robot joint with the highest precision and fastest response speed in the industry.

Take medical robots as an example. Medical robots are mostly used for in - human surgeries, so they have extremely strict requirements for indicators such as repeat positioning accuracy, power consumption and heat generation, safety protection, and torque control of core components.

In humanoid robots, the self - developed encoder of Zero Difference Cloud Control can achieve more precise control of joint positions, ensuring that robots can accurately reach the target position during operations such as material handling and parts assembly, thereby improving production efficiency and product quality. This can be applied in scenarios such as parts assembly on automobile parts production lines.

Product picture of Zero Difference Cloud Control (Source/Enterprise)

Currently, there are mainly three transmission methods for the "torso" and "limbs" of humanoid robots: harmonic reducers, planetary reducers, and planetary roller screws. Planetary roller screws are used for linear drive, while joints driven by harmonic reducers or planetary reducers are used for rotational motion.

Planetary reducers have strong load - bearing capacity, can withstand large torques and loads, and have relatively low costs. When applied on a large scale, they can reduce the overall equipment cost. However, the single - stage transmission ratio of planetary reducers is relatively small, making them more suitable for heavy - load working conditions and motion structures with relatively low precision requirements.

"One of the advantages of planetary reducers is that China has a complete industrial chain foundation, and the relevant processing equipment has a large presence in the domestic machining industry. In addition, the structure of planetary reducers is simple, and the design can be flexibly modified. Its gears can be easily integrated with other components of the joint in the design," pointed out Jia Xiqing.

However, for humanoid robots, which have complex structures and a large number of joints (more than 40), joints are required to not only have a sufficiently high power density but also be strictly controlled in terms of volume and weight to fit the compact body of humanoid robots. Therefore, planetary reducers may be somewhat lacking in this regard, while harmonic reducers show their significant advantages. Harmonic reducers can achieve a larger transmission ratio in the same space and enable robots to perform fine - operation tasks through higher transmission precision and smaller backlash.

Jia Xiqing told Hard Krypton that Zero Difference Cloud Control focuses on joints using the harmonic reducer solution. Its joints are small in volume and light in weight, which coincides with the requirements of the lightweight structure of humanoid robots. Moreover, harmonic reducers have extremely high transmission precision and a large single - stage transmission ratio, ensuring extremely high precision in the joint movement of robots.

Of course, the current harmonic solution still has its limitations. On the one hand, harmonic reducers are limited by high thresholds for processing equipment, large capital investment, strict processing technology requirements, and more critical technical challenges such as materials, heat treatment, and tooth profile design. Enterprises need to invest a large amount of capital and manpower in R & D and technology accumulation. On the other hand, in the current situation where mass production of humanoid robots is difficult to achieve, harmonic reducers, as core components, also face the contradiction of being unable to reduce costs in the short term and having limited large - scale applications.

"In recent years, China has been accelerating the reduction of the gap between standard harmonic reducers and imported ones. However, it is still very difficult to achieve in - depth customization of harmonic robot joints like the planetary solution at present," Jia Xiqing admitted. "Currently, enterprises are still trapped in the chicken - and - egg dilemma: in - depth customization requires large - volume orders, and large - volume orders require in - depth customized prototypes for testing first. In addition, the price of harmonic reducers is about five times that of planetary reducers, which further limits the larger - scale application of harmonic robot joints."

Jia Xiqing believes that the different performances of harmonic and planetary transmission methods in terms of service life, impact resistance, noise, and failure forms make it difficult for the market to determine which transmission method is better in the short term. Harmonic and planetary reducer joints will coexist in the long term, and choosing the appropriate transmission method according to the final requirements of the humanoid robot in different scenarios is still the optimal solution.

Standardization + Multiple models, wide range of applicable scenarios

According to the "2024 Research Report on the Chinese Humanoid Robot Industry", according to different mass - production scales, the cost reduction of humanoid robots can be roughly divided into three stages: for small - scale production of thousands of units, the cost can be reduced by 20% - 30% to about $100,000; for production of tens of thousands of units, the cost can be reduced by 50% to $50,000; for large - scale mass production of hundreds of thousands to millions of units, the cost can be reduced by 70% - 80% to $20,000 - $30,000.

Once mass production is achieved, the market for core components represented by joints will also experience explosive growth. Shipment volume is the core of the marginal effect. Therefore, to cover as many users as possible, Zero Difference Cloud Control has released multiple models of joints to meet the needs of different fields and application scenarios, including the main eRob straight - tube Type I series and the eRob corner Type T series.

In terms of size, the smallest module of the eRob joint module has a diameter of only 70mm and a maximum allowable torque of 70Nm, while the largest module has a diameter of 170mm and a maximum allowable torque of 1180Nm. Compared with other joint modules with the same load - bearing capacity in the market, it has the smallest volume. This characteristic of achieving high - torque output with a small size has significant advantages in practical applications.

For example, in the logistics and warehousing scenario, users will choose the smallest module of the joint to drive the robot in a limited environment, meeting the need for flexible operation in a narrow warehousing space. In surgical robots, a smaller joint volume can reduce the spacing between multiple surgical robotic arms, allowing various surgical instruments to perform operations through a smaller wound. In addition, a smaller joint volume also provides the possibility for the external dimensions of humanoid robots to gradually approach those of real human bodies.

For downstream customers, Zero Difference Cloud Control helps enterprises quickly complete the assembly of robots by building standardized and multi - model joint modules, saving a large amount of manpower and time costs in the selection, design, procurement, and assembly of hundreds of mechanical and electronic devices, enabling robot companies to truly focus on the development of robot bodies and applications.

Zero Difference Cloud Control's self - owned production workshop (Source/Enterprise)

In recent years, the trend of domestic substitution of robot joints has become increasingly strong, and the long - term dependence on imports is gradually being broken.

Jia Xiqing told Hard Krypton that except for some chips that need to be imported, all core components of Zero Difference Cloud Control are currently from self - developed and domestic supply chains, including harmonic reducers, encoders, drivers, frameless torque motors, and control software algorithms.

"Complete domestic substitution is the manufacturing goal of our products. Currently, we are also testing domestic chips internally. We believe that in the near future, we will definitely not be affected by the 'chokepoint' problem," said Jia Xiqing.

In addition, the company has multiple production workshops, including a five - axis precision machining workshop, a testing workshop, and a precision assembly and testing workshop. It conducts a full inspection of the backlash, rigidity, noise, transmission precision, and jitter of each joint module after loading. After assembly, the joint will enter the internal testing workshop for testing under various working conditions, such as simulating the operation of industrial robot joints under different loads and rotation speeds, to avoid product failures after they enter the market.

The sudden popularity of the humanoid robot track has brought the supply chain behind it to the forefront. However, for these companies, the most stable source of cash will not come from the humanoid robot industry. To survive the cycle, they still have to rely on customers with more mature commercialization. Serving these customers is also a more important topic at present.